Very interested. Any material would be good, but if given choices SS would be good. Keep us posted. Thx.As I said, bare with me and when the first is done I’ll post photos and if people like what they see we can take it from there?

I’ll be fully transparent on material & machining costings.

Daniel,

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mr Riggs Hydraulic Clutch Conversion

- Thread starter Bewarethemoon

- Start date

Mrriggs used cast iron for his slave body and some sort of SS for the piston I believe? So something like SS seems sufficient, but I’m certainly not a metals expert by any stretch. I know brakes will use cast for housings and SS for the actual pistons. Anyone know what might drive those choices? I’d be happy with whatever works

Mrriggs used cast iron for his slave body and some sort of SS for the piston I believe? So something like SS seems sufficient, but I’m certainly not a metals expert by any stretch. I know brakes will use cast for housings and SS for the actual pistons. Anyone know what might drive those choices? I’d be happy with whatever works

Casting refers to the manufacturing process not the material used e.g. cast, forged, machined etc.

On a large scale a manufacturer would choose to ‘cast’ a calliper body as it would be more cost effective. On a smaller scale a manufacturer may choose to ‘machine’ the same part, take Hel Performance for example, a company local to me who can machine you a custom calliper. Their products are often used in BSB.

Mr Riggs slave cylinder body was machined out of steel, can’t remember the specific grade off hand.

Daniel.

Last edited:

Ahh, of course, that all makes perfect sense. Thanks Daniel!

A couple of years back when I was in university I took a product development elective for my engineering degree. I wanted to do something XS related and at the time there was another thread on the Mr Riggs style clutch doing the rounds so I thought it would be handy to look into something like that.

So I ended up writing a report, cant remember how long but prob 10k words at least going through the whole thing from start to finish, calculating the forces involved, diameters of slave cylinders, the materials, o-rings, surface finish, tolerences, processes etc. I made some spreadsheets and did some drawings, even 3d printed some prototypes and stuff.

It was a pretty decent body of work, the only problem is, all my university stuff is currently at my moms house about 70 miles away and here in Ireland we cant travel more than 5kms till at least April so I'm afraid I'm no help until at least then.

So I ended up writing a report, cant remember how long but prob 10k words at least going through the whole thing from start to finish, calculating the forces involved, diameters of slave cylinders, the materials, o-rings, surface finish, tolerences, processes etc. I made some spreadsheets and did some drawings, even 3d printed some prototypes and stuff.

It was a pretty decent body of work, the only problem is, all my university stuff is currently at my moms house about 70 miles away and here in Ireland we cant travel more than 5kms till at least April so I'm afraid I'm no help until at least then.

I'd say aluminum would work fine, 6061 more specifically. Pretty much every factory clutch slave is aluminum, most calipers are aluminum now. And the aftermarket slaves for ducati/aprillia etc are aluminum.

Mine was made from 516 stainless because it was available.

Mine was made from 516 stainless because it was available.

StainlessJust so I can start to get the ball rolling, what would you guys prefer these made from?

Stainless?

6061 or similar?

Or Titanium if you’re feeling fancy?

Daniel.

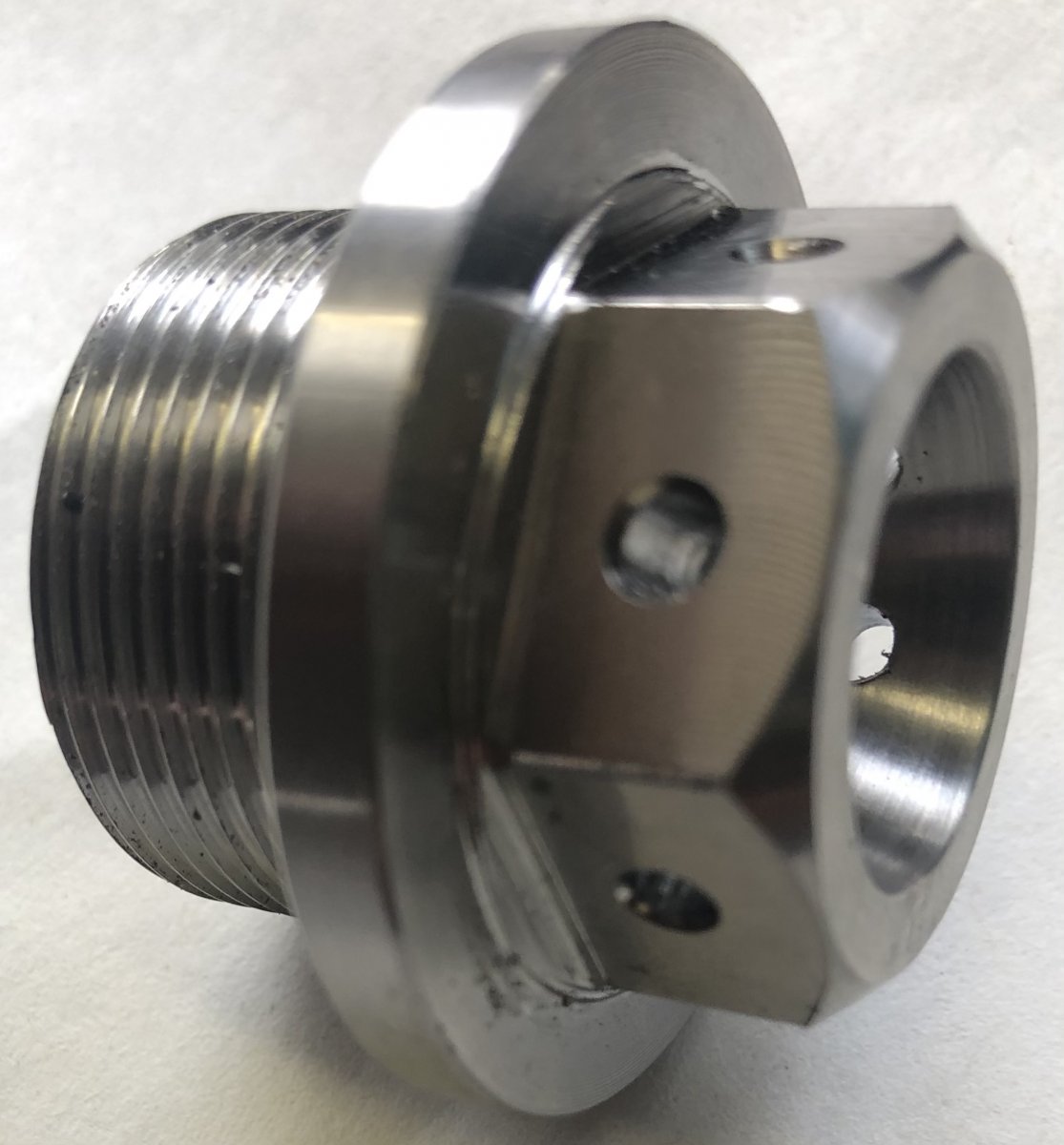

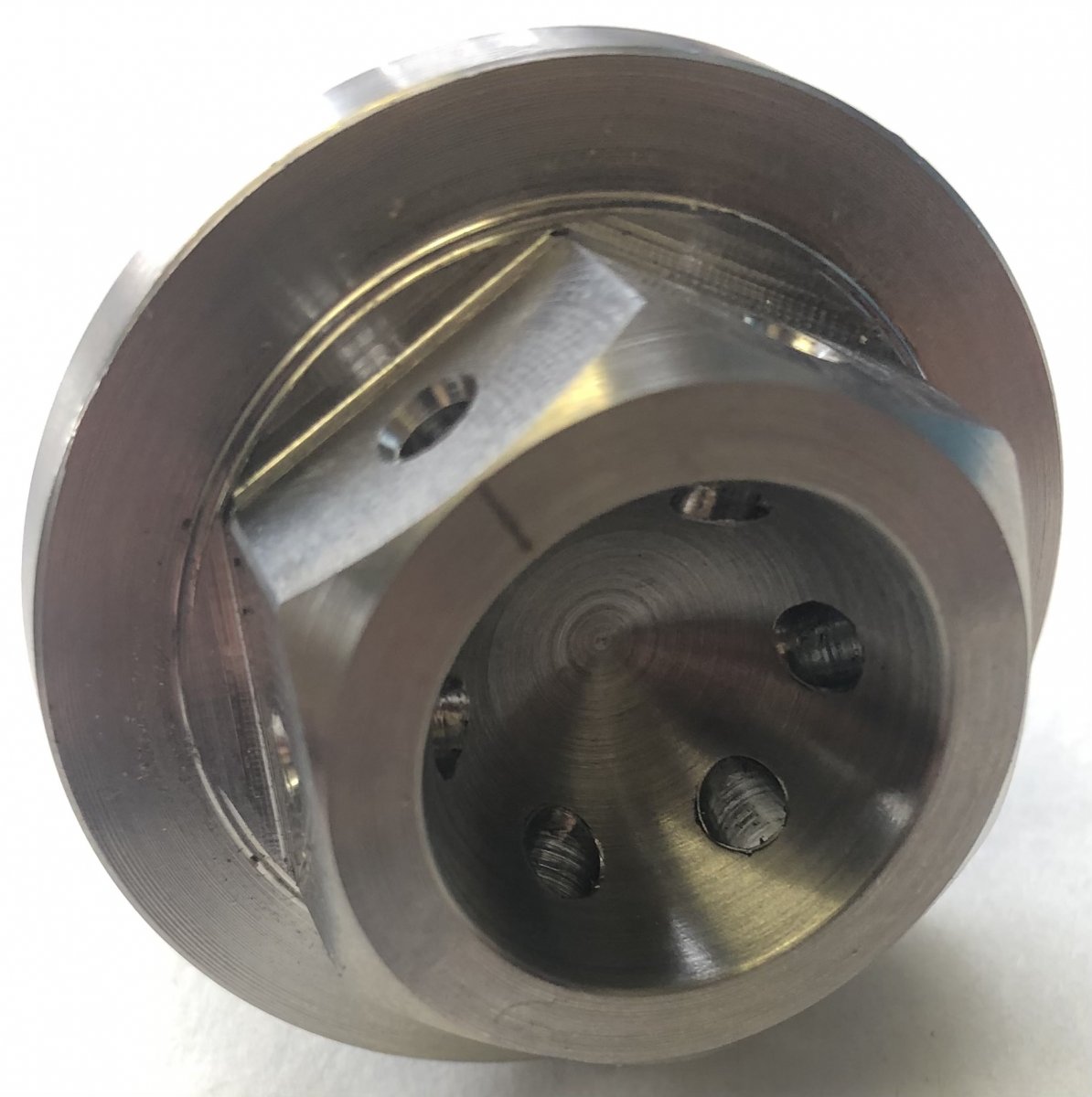

Slightly off topic but I thought it may be interesting to those concerned, if only to show my machinist friends ability.

A Titanium ‘race’ sump drain plug I had him make, there’s a 20mm x 3mm Neodymium magnet pressed into the bottom.

A Titanium ‘race’ sump drain plug I had him make, there’s a 20mm x 3mm Neodymium magnet pressed into the bottom.

Nice. I like all things shiny!Slightly off topic but I thought it may be interesting to those concerned, if only to show my machinist friends ability.

A Titanium ‘race’ sump drain plug I had him make, there’s a 20mm x 3mm Neodymium magnet pressed into the bottom.

View attachment 186317 View attachment 186318 View attachment 186319

Seems Stainless is the preferred material?

I’ve been in contact with my guy to see what he has, along with some Bronze for the little press in pushrod bushing.

Who knows guys, we may end up with some F1 off cuts on our hands here, I’ll wait and see.

Daniel.

I’ve been in contact with my guy to see what he has, along with some Bronze for the little press in pushrod bushing.

Who knows guys, we may end up with some F1 off cuts on our hands here, I’ll wait and see.

Daniel.

Daniel - Are you working on a similar slave cylinder as the one done by Mr. Riggs?

Yes, almost identical really, just a couple minor alterations.

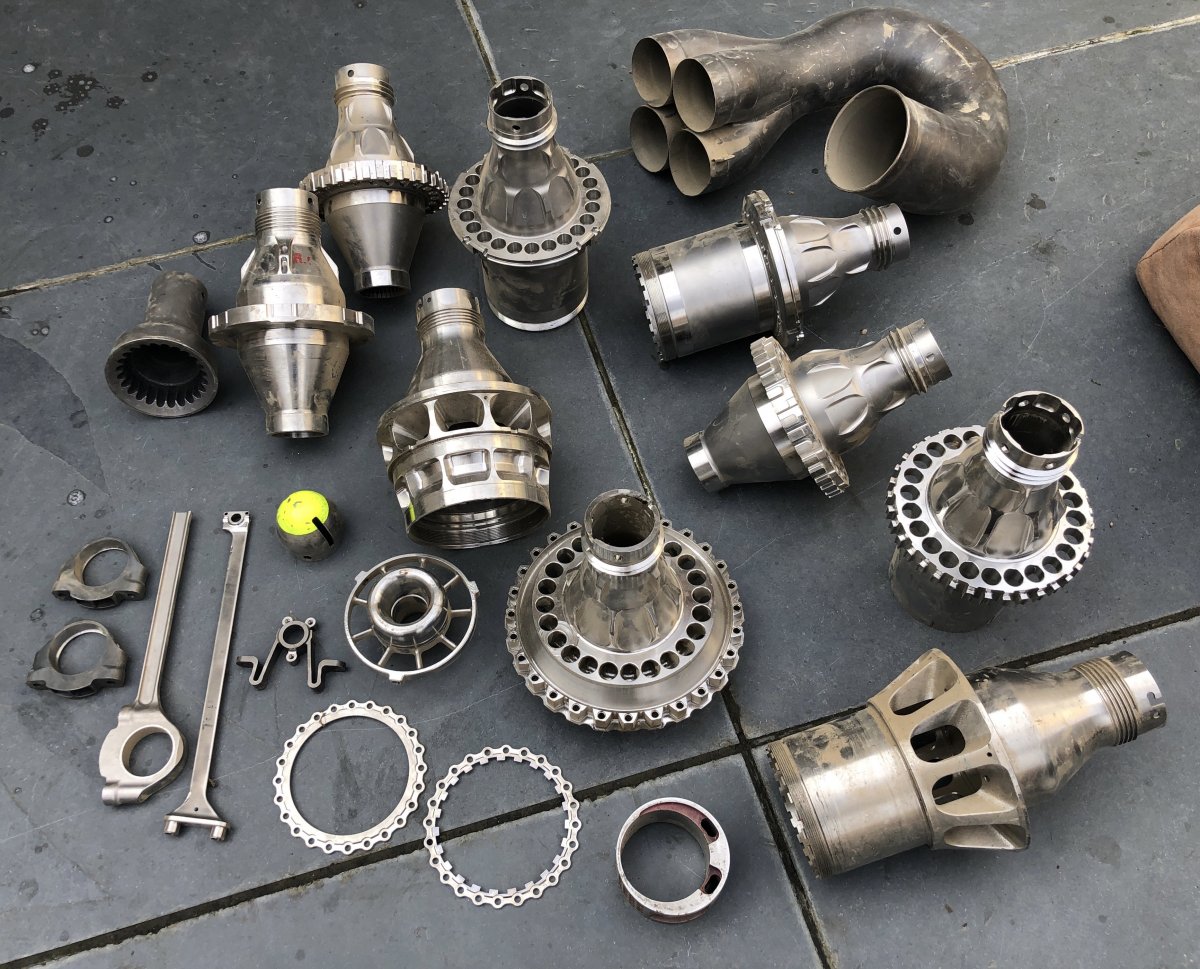

These are a photos of a few of the F1 ‘odds’ my metal guy has laying around. Thought this might be of interest to some.

Daniel.

Daniel.

SEd27

XS650 Addict

Would be interested as well, provided the pricing was right. This said, I realize there may be a bit of a premium on a small batch run.

Purchased an Aprilia slave to work on a conversion, but buggered the piston. Found out it is almost impossible to get a replacement (without purchasing the entire assembly).

As well, the small sample of research I did on the the Aprilia forums found that many were complaining about the stock units leaking.

Purchased an Aprilia slave to work on a conversion, but buggered the piston. Found out it is almost impossible to get a replacement (without purchasing the entire assembly).

As well, the small sample of research I did on the the Aprilia forums found that many were complaining about the stock units leaking.

Last edited:

/These are a photos of a few of the F1 ‘odds’ my metal guy has laying around. Thought this might be of interest to some.

Hope Mr. Stroll doesn't see these photos. We could a whole nuther copying investigation though I don't see any brake ducts

Hoping F1 tv has coverage of testing next week.

Would be interested as well, provided the pricing was right. This said, I realize there may be a bit of a premium on a small batch run.

Purchased an Aprilia slave to work on a conversion, but buggered the piston. Found out it is almost impossible to get a replacement (without purchasing the entire assembly).

As well, the small sample of research I did on the the Aprilia forums found that many were complaining about the stock units leaking.

This is just a very rough figure as I won’t know more until we make the first but I wouldn’t expect I’ll be able to offer them for much less than $150.

Daniel.

Is that for the slave cylinder only or a kit with lines etc.This is just a very rough figure as I won’t know more until we make the first but I wouldn’t expect I’ll be able to offer them for much less than $150.

Daniel.

I wasn’t intending on supplying hydraulic line.

I was intending on supplying the slave assembly complete with banjo bolt, crush washer and a bleed nipple, along with a circlip for mounting.

As I’ve said this is just a very rough preliminary estimation and I won’t be able to be more accurate until I have had mine made.

That being said I feel $150 is quite a low price, considering a kit used to be for sale on TwinsInn.de for $300 (that did include hydraulic line). There was also a poll a while back and general consensus seemed to be that people were comfortable with $150-200.

But please tell me your thoughts, I’m open to feedback and this will be first venture.

Daniel.

I was intending on supplying the slave assembly complete with banjo bolt, crush washer and a bleed nipple, along with a circlip for mounting.

As I’ve said this is just a very rough preliminary estimation and I won’t be able to be more accurate until I have had mine made.

That being said I feel $150 is quite a low price, considering a kit used to be for sale on TwinsInn.de for $300 (that did include hydraulic line). There was also a poll a while back and general consensus seemed to be that people were comfortable with $150-200.

But please tell me your thoughts, I’m open to feedback and this will be first venture.

Daniel.

For me, the less I have to do to, the better to source all the required parts. Maybe once you finalize the manufacturing of the slave, you could offer the cylinder by itself or a plug and play kit.I wasn’t intending on supplying hydraulic line.

I was intending on supplying the slave assembly complete with banjo bolt, crush washer and a bleed nipple, along with a circlip for mounting.

As I’ve said this is just a very rough preliminary estimation and I won’t be able to be more accurate until I have had mine made.

That being said I feel $150 is quite a low price, considering a kit used to be for sale on TwinsInn.de for $300 (that did include hydraulic line). There was also a poll a while back and general consensus seemed to be that people were comfortable with $150-200.

But please tell me your thoughts, I’m open to feedback and this will be first venture.

Daniel.

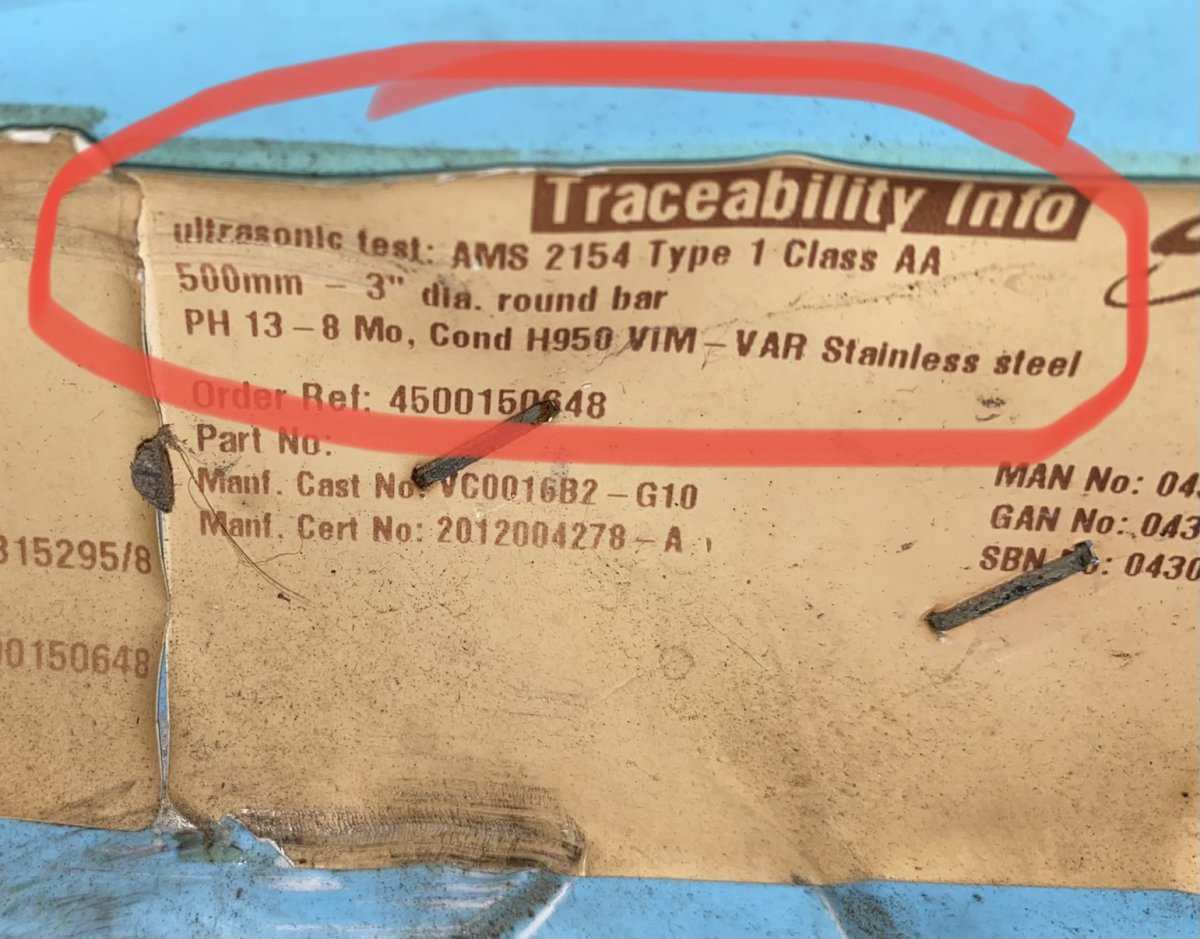

Spoke to my metal guy and I’ve bought some material.

We have 13-8 Stainless for the slave body and piston, from the F1 Mercedes team no less!

And something called Toughmet-3 TS160 a Copper-Nickel-Tin alloy for the press in pushrod bushing

https://materion.com/products/high-performance-alloys/toughmet/toughmet-tempers

Daniel.

We have 13-8 Stainless for the slave body and piston, from the F1 Mercedes team no less!

And something called Toughmet-3 TS160 a Copper-Nickel-Tin alloy for the press in pushrod bushing

https://materion.com/products/high-performance-alloys/toughmet/toughmet-tempers

Daniel.

Similar threads

- Replies

- 25

- Views

- 2K