https://www.xs650.com/threads/video-of-my-potters-wheel-tank-tumbler-cleaner.62917/

Link to my tank tumbling cleaning thread above, wherein I put abrasive materials inside a tank and tumble it in order to clean the inside.

I have used Harbor Freight resin media and their ceramic media. Both work. Will clean a tank enough that it is perfectly suitable to be put into use.

However, I would like to make a tank that is SPOTLESS.

The problem is that both of those HF medias cannot get into the tiny pits. This pic is a HUGE blow-up, it makes it look worse than it really is, but nontheless, the surface gets cleaned very well, but the pits hold their rust. The media just can't get in there. I've tried adding Play Sand to the mix, but it doesn't help -- tumbling is not like blasting sand at 90 PSI.

The next thing I want to try is short drywall screws. The problem with them is they only have a single sharp point.

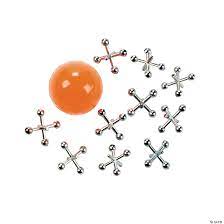

What would be ideal would be something like jacks, but with all points, and all the points being very sharp.

I know this is a long shot, but can anyone think of anything that exists like what I want?

If not, my next try will be with the drywall screws.

Link to my tank tumbling cleaning thread above, wherein I put abrasive materials inside a tank and tumble it in order to clean the inside.

I have used Harbor Freight resin media and their ceramic media. Both work. Will clean a tank enough that it is perfectly suitable to be put into use.

However, I would like to make a tank that is SPOTLESS.

The problem is that both of those HF medias cannot get into the tiny pits. This pic is a HUGE blow-up, it makes it look worse than it really is, but nontheless, the surface gets cleaned very well, but the pits hold their rust. The media just can't get in there. I've tried adding Play Sand to the mix, but it doesn't help -- tumbling is not like blasting sand at 90 PSI.

The next thing I want to try is short drywall screws. The problem with them is they only have a single sharp point.

What would be ideal would be something like jacks, but with all points, and all the points being very sharp.

I know this is a long shot, but can anyone think of anything that exists like what I want?

If not, my next try will be with the drywall screws.