Bought it thx! I think I’ll put it in the ‘76.You may have better luck searching for a whole left cover. Here's one from Canada for not too bad a price .....

https://www.ebay.com/itm/304353114018?hash=item46dcdbf7a2:g:9-cAAOSw32lYzt8b

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New addition to the garage

- Thread starter bosco659

- Start date

I figured you did when I went to look at the link.

I see you did an edit and added questions to your post #99. No need to weld up the original arm hole, just drill another closer to the center of rotation. The late arm was the same part, just had the hole drilled closer in .....

The distance from the center is the same on the XS400 "1L9" worm so you could get a measurement for the hole location. Early 650 worms were even shorter and while that did give better plate separation, it made for a very hard lever pull. I tried one but only briefly because of that.

Yes, the XS400 "1L9" worm is clocked a little differently but a small, easy mod makes it work. See post #65 here for details .....

https://www.xs650.com/threads/200-special.51454/page-4

The distance from the center is the same on the XS400 "1L9" worm so you could get a measurement for the hole location. Early 650 worms were even shorter and while that did give better plate separation, it made for a very hard lever pull. I tried one but only briefly because of that.

Yes, the XS400 "1L9" worm is clocked a little differently but a small, easy mod makes it work. See post #65 here for details .....

https://www.xs650.com/threads/200-special.51454/page-4

Did you use a belt sander to remove the 1mm?I see you did an edit and added questions to your post #99. No need to weld up the original arm hole, just drill another closer to the center of rotation. The late arm was the same part, just had the hole drilled closer in .....

View attachment 207346

View attachment 207347

The distance from the center is the same on the XS400 "1L9" worm so you could get a measurement for the hole location. Early 650 worms were even shorter and while that did give better plate separation, it made for a very hard lever pull. I tried one but only briefly because of that.

Yes, the XS400 "1L9" worm is clocked a little differently but a small, easy mod makes it work. See post #65 here for details .....

https://www.xs650.com/threads/200-special.51454/page-4

No, I simply worked the top of the nylon worm against some coarse sand paper laid on a plate of glass .....

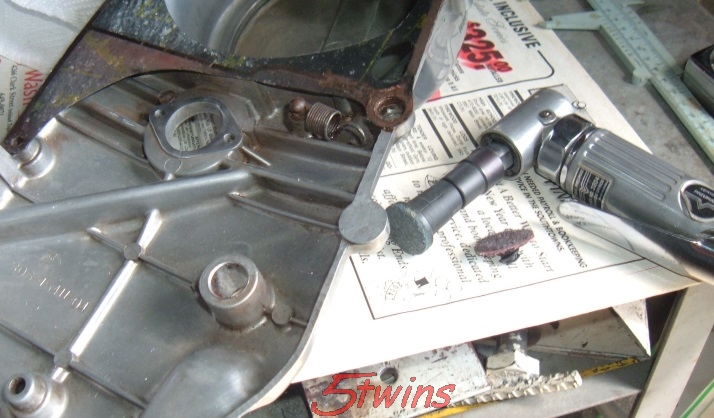

There's another little mod you may find you need. On many of the side covers (most I've seen), the hole that the worm mounts into has a little lip or ridge around it .....

The mounting tabs don't fit against the case and when you screw the worm down tight, it can distort the nylon part and bind the worm up. I "buff" it off with Roloc discs .....

There's another little mod you may find you need. On many of the side covers (most I've seen), the hole that the worm mounts into has a little lip or ridge around it .....

The mounting tabs don't fit against the case and when you screw the worm down tight, it can distort the nylon part and bind the worm up. I "buff" it off with Roloc discs .....

I used a belt sander on mine. With it just sittin' on the bench, it was too easy not to...

More “stuff” for the toys arrived today!

}

}

Last edited:

New shoes on the bike now. Very little clearance for the 130/90-16 rear tire. Just need to get the carbs back on and it’s ready for a road test when the weatherman says ok. This bike is actually in pretty nice shape.

Holy clean Batman!

Yea! I don't think any of mine looked that clean when they left the factory! Definitely not since I've owned them!Holy clean Batman!

I guess I’ll be needing new air filters. Drilled holes to shake some of the $hit out but realized the foam had disintegrated. Get “stock like” replacements or UNI’s?

I bought stock ones for my rebuild but have since seen great advise on rebuilding air filters on the forum. If you used the UNIs you could dump the crankcase vent onto them as 5T has done.

I guess I’ll be needing new air filters. Drilled holes to shake some of the $hit out but realized the foam had disintegrated. Get “stock like” replacements or UNI’s?

Your stock cages make a good base to wrap with filter foam if you’re interested. Filter foam can be purchased in sheets online. Uni sells some, most of them are green. I also bought a bottle of filter oil, but it’s really sticky stuff and a mess to work with. Regular motor oil works just as well.

I’ll look into this. Do you cut and glue the foam to form a “donut”?Your stock cages make a good base to wrap with filter foam if you’re interested. Filter foam can be purchased in sheets online. Uni sells some, most of them are green. I also bought a bottle of filter oil, but it’s really sticky stuff and a mess to work with. Regular motor oil works just as well.

View attachment 207922View attachment 207923View attachment 207924

Last edited:

I’ll look into this. Do you cut and glue the foam to form a “donut”?

No I just cut the foam into strips and wrap it around the cage and overlap the ends, I cut the strip about a half inch too wide so it fits tight against the edges. To hold it in place, what I use is just something I had on hand, I have a big roll of green twist tie wire, that they sell in plant nurseries and hardware stores for tying up plants. I just cut a couple of long pieces and wrap around the filter and twist the ends. That way it’s easy to remove for cleaning and re oiling.

Ok sounds easy. What thickness did you buy? The stuff I saw on Amazon was 5/8” which I thought was a bit thick. I see theres 3/8” available elsewhere.No I just cut the foam into strips and wrap it around the cage and overlap the ends, I cut the strip about a half inch too wide so it fits tight against the edges. To hold it in place, what I use is just something I had on hand, I have a big roll of green twist tie wire, that they sell in plant nurseries and hardware stores for tying up plants. I just cut a couple of long pieces and wrap around the filter and twist the ends. That way it’s easy to remove for cleaning and re oiling.

Ok sounds easy. What thickness did you buy? The stuff I saw on Amazon was 5/8” which I thought was a bit thick. I see theres 3/8” available elsewhere.

I didn’t buy sheet foam, I bought what was supposed to be a replacement foam filter,

but it didn’t work, so I cut it up and made my own. It’s about 3/8” thick, at first I double wrapped it, but it seemed too restrictive to me, so it’s now a single layer.

Yes I thought about trying to find a pre made donut of foam but thought I would have to buy too many before I found the correct one. I think the sheet will be the most cost effective solution. I want to get this done soon so I’ll have to hunt down a local supplier with stock. Thanks for the intel!I didn’t buy sheet foam, I bought what was supposed to be a replacement foam filter,

View attachment 207930

but it didn’t work, so I cut it up and made my own. It’s about 3/8” thick, at first I double wrapped it, but it seemed too restrictive to me, so it’s now a single layer.

View attachment 207929

Just ordered the foam sheet. Got one of two cleaned up good enough for the foam wrap. Dirty job.

thanks for the advice MM!

thanks for the advice MM!

You’re welcome! Good luck with your project!

Similar threads

- Replies

- 24

- Views

- 1K