coder72

XS650 Member

Hi All,

It's been a while since I rebuilt an engine so I'm hoping someone with more expeience with rebilding the XS2 (or similar) can help.

I am getting ready to start putting my '72 XS2 back together and am going over the various bits and pieces and notice that the new seals I purchased do not have a ridge on the outer surface.

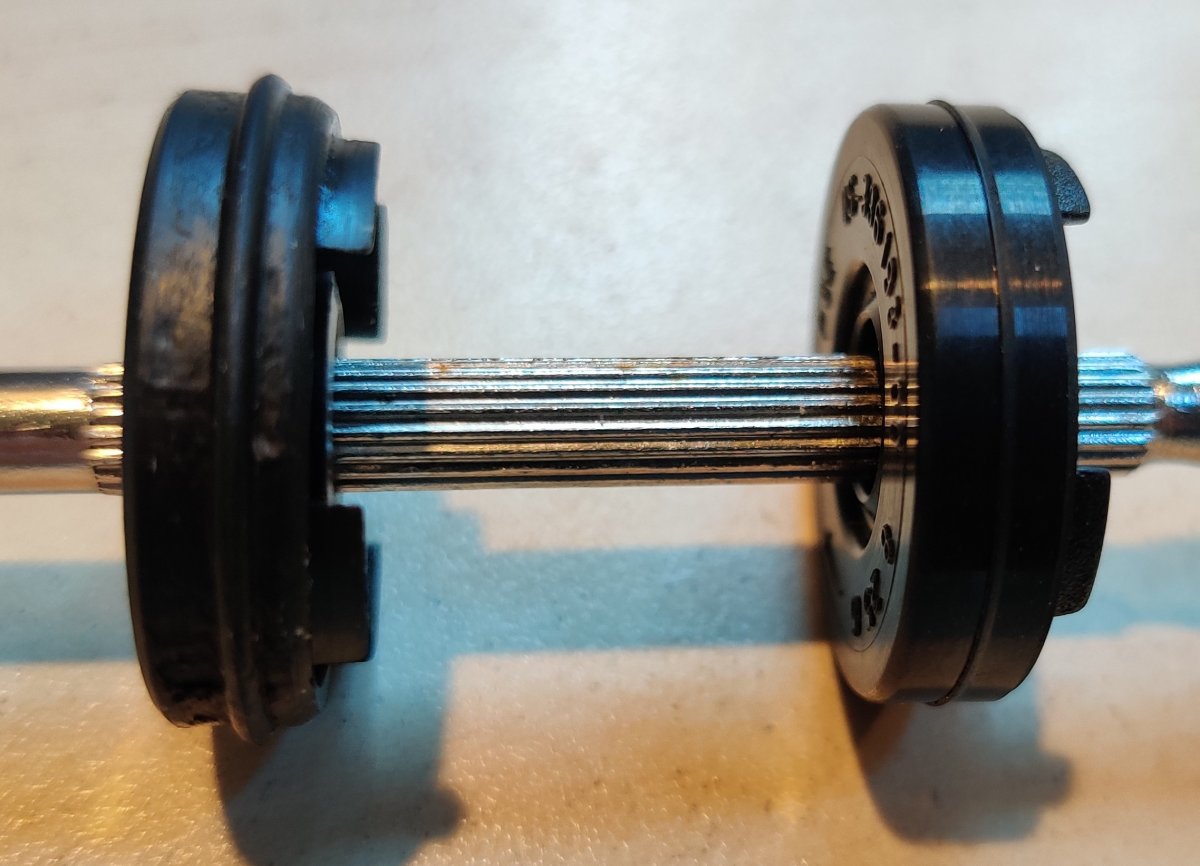

I've attached a photo of the clutch pushrod seal which shows this feature. The original seal is on the left and the new seal I purchased to replace it, without the ridge is on the right.

I would think that this is a pretty important feature but am I wrong? Is it possible to get new original seals with the ridge?

It's been a while since I rebuilt an engine so I'm hoping someone with more expeience with rebilding the XS2 (or similar) can help.

I am getting ready to start putting my '72 XS2 back together and am going over the various bits and pieces and notice that the new seals I purchased do not have a ridge on the outer surface.

I've attached a photo of the clutch pushrod seal which shows this feature. The original seal is on the left and the new seal I purchased to replace it, without the ridge is on the right.

I would think that this is a pretty important feature but am I wrong? Is it possible to get new original seals with the ridge?