Things lined up rather nicely for me this week. Had a couple of free days before starting a new major project next week that will severely limit time in Papa's Shop. Honey only made up a short ‘H Do List’, so able to raise the shop doors.

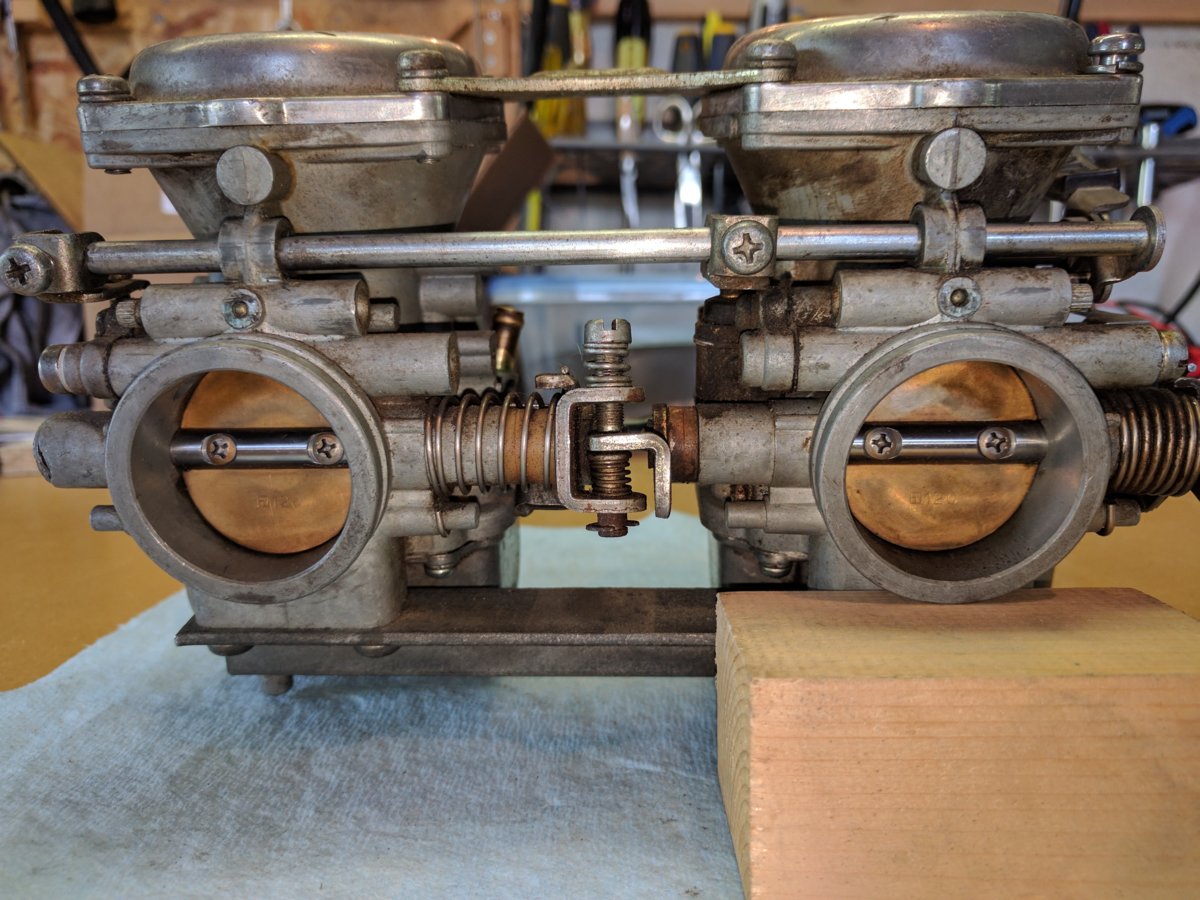

Just entered the O.R. ready for open carb surgery.

You know I never, ever, thought the day would come that I would say I enjoy working on carbs, but I find it somehow therapeutic. Huh. Been into both sets of mine more than once over the last 12 months, as well as in years past, so now it kinda feels like going home again.

It’s all the work taking everything apart to get them off and then put back on again that I hate.

And then there's the added anxiety of wondering if they'll recover from surgery.

I know we all like to beat up on Mike’s/XS 650 Direct, and sometimes for good reason but, have to give them props when due. They do sell carb starter circuit gaskets that appear to be no longer available OEM. And, they do ship fast. Order placed Monday night, received Wednesday aft. No complaints there.

Read this thread by gggGary,

http://www.xs650.com/threads/carb-t...ft-butterfly-screw-removal.46423/#post-464664

Thanks g's, great thread!

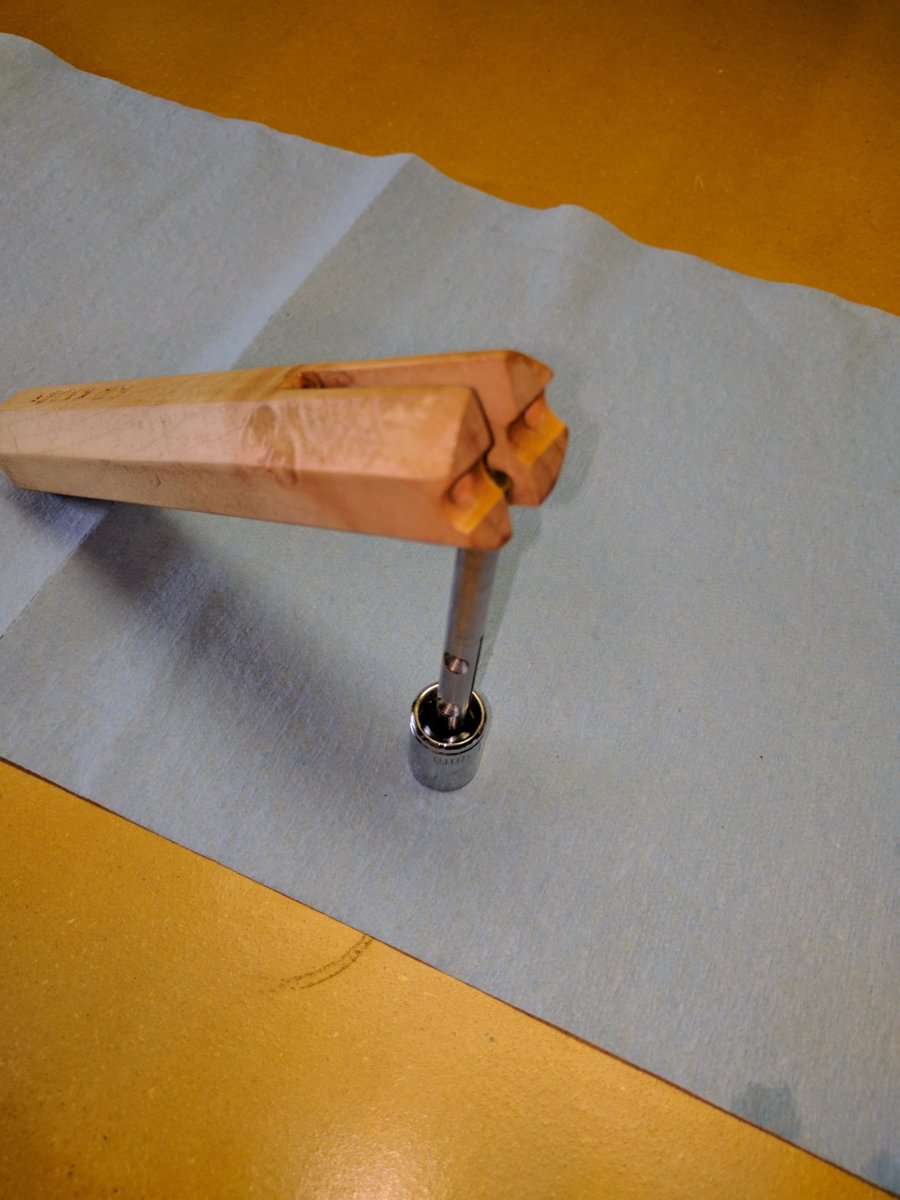

I made this throttle shaft support from a piece of hard maple from one of the scraps bins to put where the air/fuel mix and the sun don't shine. I know you guys could rebuild the carbs in the time it took me to make this, but I love an excuse to build a tool or jig and I'm back in my comfort zone…...working with wood!

So, to the O.R. 3 screws broke free and spun out relatively easily, with ‘STICK IT’ but, and there’s always a but, isn't there? One screw would just not let go. She hung in there, despite carefully using Vessel / Impacta JIS screwdrivers,and heat from a small soldering iron, it would not let go and eventually boogered the screw head. OK.

Back to the oft quoted, much ignored Carb Guide by 5twins and Grizld1.

I don’t know what we’d do without this amazing chronicle. Kudos gentlemen!

http://www.amckayltd.com/carbguide.pdf

Quote from this infamous document:

If the screws must be drilled out, bear in mind that a trip to the machine shop will be cheaper than new carburetors.

Huh, getting a little more concerned after reading that. This procedure obviously isn't for the faint of heart, but my other carbs have been at the machinist for over 2 weeks now, not waiting anymore. Gonna take a chance and give er a go. Figured if I mess up real bad I’ll find another butterfly shaft somewhere. If you see a new Wanted ad in the classifieds for a 78-79 BS38 butterfly shaft you'll know I didn't make out so well.

Another quote from the C-Bible.

Member Fry posted an excellent tip on removing the screws. After carefully drilling the screw heads and removing throttle springs and stops so that the plates would rotate fully, he was able to grip the staked tips of the screws with needlenose pliers and back them out. Thanks, Fry! When you reassemble, use blue Loctite and restake the screws with locking pliers (Visegrips) or waterpump pliers (Channel Locks).

This worked amazingly well. Just as described.Probably took a LOT longer than it needed to, but it was my first time and I figured slow and steady wins this race. I stopped often to check my progress , kept reducing drill bit size as I approached butterfly screw hole and kept blowing compressed air through carb inlet to remove shavings.

So far this story is marching merrily along, but now things go south fast.

When I initially inspected these new to me carbs once received, it was obvious they had suffered blunt force trauma.

If you look at the end of the throttle shaft of the right carb (left in the picture) you can see some damage.

Here you can see the bent choke plunger pickle fork...

And this shows the damage to the throttle shaft o-ring housing.

Should have just torn them right down in the first place, but took a chance that that damage wouldn't affect the o-ring seal.

If there is a silver lining to this cloud, if I hadn't taken that chance, I still as of yet wouldn't have had her out for a few short trips.

I can't see how these can be saved. The interior brass throttle shaft sleeve is undamaged, but this dent in the o-ring housing forces the o-ring out of round so never gonna fully seal. I have nothing to lose by trying push that dent out, but I can't really see that being an effective solution. Carb bodies are soft, maybe with a little heat it could be reformed but I expect any attempt at that would just crack it and break it off. And it's pretty unrealistic to think that even if I could reform it that I would be able to be accurate enough to achieve a proper seal.

Don't have a milling machine, maybe an end mill would work, but I wonder if there would be enough meat left to do that?

Guess I could pull the carbs off 'Blackie’, my 78E, rebuild them and use them. That and clean up the electrics are the first couple of jobs on the list anyways, but I hate to do that to her and still need 2 working sets of carbs anyways.

Not every story has a happy ending, sadly this one doesn't.

Other than 'go pour yourself a double’, anybody got any suggestions?

Just entered the O.R. ready for open carb surgery.

You know I never, ever, thought the day would come that I would say I enjoy working on carbs, but I find it somehow therapeutic. Huh. Been into both sets of mine more than once over the last 12 months, as well as in years past, so now it kinda feels like going home again.

It’s all the work taking everything apart to get them off and then put back on again that I hate.

And then there's the added anxiety of wondering if they'll recover from surgery.

I know we all like to beat up on Mike’s/XS 650 Direct, and sometimes for good reason but, have to give them props when due. They do sell carb starter circuit gaskets that appear to be no longer available OEM. And, they do ship fast. Order placed Monday night, received Wednesday aft. No complaints there.

Read this thread by gggGary,

http://www.xs650.com/threads/carb-t...ft-butterfly-screw-removal.46423/#post-464664

Thanks g's, great thread!

I made this throttle shaft support from a piece of hard maple from one of the scraps bins to put where the air/fuel mix and the sun don't shine. I know you guys could rebuild the carbs in the time it took me to make this, but I love an excuse to build a tool or jig and I'm back in my comfort zone…...working with wood!

So, to the O.R. 3 screws broke free and spun out relatively easily, with ‘STICK IT’ but, and there’s always a but, isn't there? One screw would just not let go. She hung in there, despite carefully using Vessel / Impacta JIS screwdrivers,and heat from a small soldering iron, it would not let go and eventually boogered the screw head. OK.

Back to the oft quoted, much ignored Carb Guide by 5twins and Grizld1.

I don’t know what we’d do without this amazing chronicle. Kudos gentlemen!

http://www.amckayltd.com/carbguide.pdf

Quote from this infamous document:

If the screws must be drilled out, bear in mind that a trip to the machine shop will be cheaper than new carburetors.

Huh, getting a little more concerned after reading that. This procedure obviously isn't for the faint of heart, but my other carbs have been at the machinist for over 2 weeks now, not waiting anymore. Gonna take a chance and give er a go. Figured if I mess up real bad I’ll find another butterfly shaft somewhere. If you see a new Wanted ad in the classifieds for a 78-79 BS38 butterfly shaft you'll know I didn't make out so well.

Another quote from the C-Bible.

Member Fry posted an excellent tip on removing the screws. After carefully drilling the screw heads and removing throttle springs and stops so that the plates would rotate fully, he was able to grip the staked tips of the screws with needlenose pliers and back them out. Thanks, Fry! When you reassemble, use blue Loctite and restake the screws with locking pliers (Visegrips) or waterpump pliers (Channel Locks).

This worked amazingly well. Just as described.Probably took a LOT longer than it needed to, but it was my first time and I figured slow and steady wins this race. I stopped often to check my progress , kept reducing drill bit size as I approached butterfly screw hole and kept blowing compressed air through carb inlet to remove shavings.

So far this story is marching merrily along, but now things go south fast.

When I initially inspected these new to me carbs once received, it was obvious they had suffered blunt force trauma.

If you look at the end of the throttle shaft of the right carb (left in the picture) you can see some damage.

Here you can see the bent choke plunger pickle fork...

And this shows the damage to the throttle shaft o-ring housing.

Should have just torn them right down in the first place, but took a chance that that damage wouldn't affect the o-ring seal.

If there is a silver lining to this cloud, if I hadn't taken that chance, I still as of yet wouldn't have had her out for a few short trips.

I can't see how these can be saved. The interior brass throttle shaft sleeve is undamaged, but this dent in the o-ring housing forces the o-ring out of round so never gonna fully seal. I have nothing to lose by trying push that dent out, but I can't really see that being an effective solution. Carb bodies are soft, maybe with a little heat it could be reformed but I expect any attempt at that would just crack it and break it off. And it's pretty unrealistic to think that even if I could reform it that I would be able to be accurate enough to achieve a proper seal.

Don't have a milling machine, maybe an end mill would work, but I wonder if there would be enough meat left to do that?

Guess I could pull the carbs off 'Blackie’, my 78E, rebuild them and use them. That and clean up the electrics are the first couple of jobs on the list anyways, but I hate to do that to her and still need 2 working sets of carbs anyways.

Not every story has a happy ending, sadly this one doesn't.

Other than 'go pour yourself a double’, anybody got any suggestions?