I'm no toglhot!

But back together and just about ready for the tire.

Looking pretty first-rate to me!

I'm no toglhot!

But back together and just about ready for the tire.

I'm no toglhot!

But back together and just about ready for the tire.View attachment 224040

Well......What is the method for centering the rim?

Feel when tightening and a "ding ding" check, spinning the wheel, bouncing a smooth piece of metal on the spokes. "Good enough?"

Feel when tightening and a "ding ding" check, spinning the wheel, bouncing a smooth piece of metal on the spokes. "Good enough?"Cmon ol' man.... we should all be "green" with envy by now.Where does time go? pic is from Oct 11th

View attachment 231099

but same shot could have been taken today...

So I got enough crap out of the way to start in on SoDak again.

So I got enough crap out of the way to start in on SoDak again.

Dunno; looks pretty fancy to me. Handmade parts even!A fancy shmanzy resto is out of my normal wheelhouse

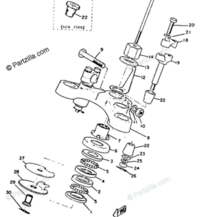

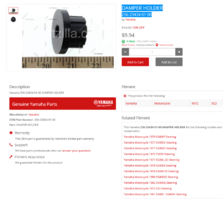

Square with flangedo your 72's have this cone style rubber bushing or the square with flange type.

Gary, I occasionally have need to bore holes in solid rubber for bushings and haven't figured out a logical way to do it. I manage, but they're usually ugly and not very accurate.

Could you post a picture of your holder and maybe a bit more detail on the procedure? Bored with a twist drill or ???

Yeah, LOL, when I first started hanging out here, I posted some stuff about my bobber build and guys asked about "build thread" & pics...I'm like: hey, I'm workin here...ain't got time for no stinkin pics - I'm getting the hang of itYou also had time to record it...this always amazes me how forum members can shoot pics while doing a repair...

5 stars to all.

when I first started hanging out here, I posted some stuff about my bobber build and guys asked about "build thread" & pics...I'm like: hey, I'm workin here...ain't got time for no stinkin pics