Mission Creep.

I recall a General back in the First Gulf War, a reporter asked 'im if they had a plan. I'll overlook that he shoulda been slapped silly for that one... but the General replied "Of course we have a plan. You have to have something to deviate from."

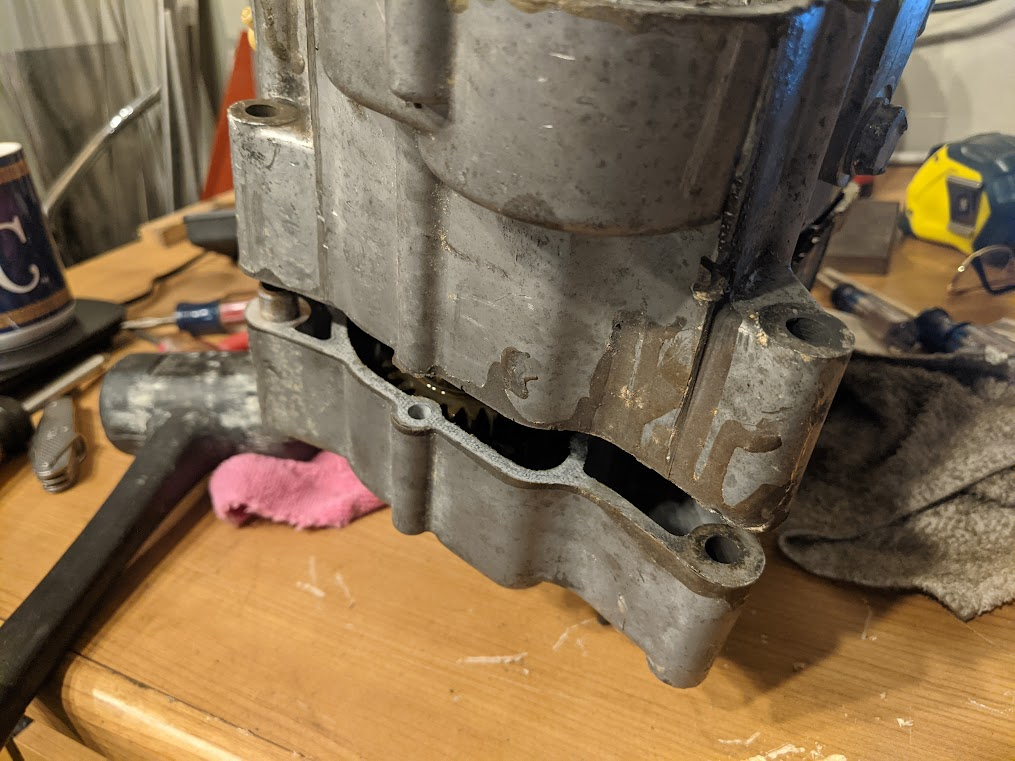

After a good cleaning in the stoddard tank, I noticed all the sealant slopped on the case halves. Yeah... Yamaha din't slop like that at the factory. Someone's split these cases before. Bein' a vertical split case, there's tons of warnings in the book on reassembly. If you've never done a vertical split, 5 speed engine, well..... it's pretty easy to fuck one up. Crap.

And... the crank was pretty notchy trying to spin it. Yeah.... guess "notchy's" bein' kind... it was damned hard to turn by hand. Crap.

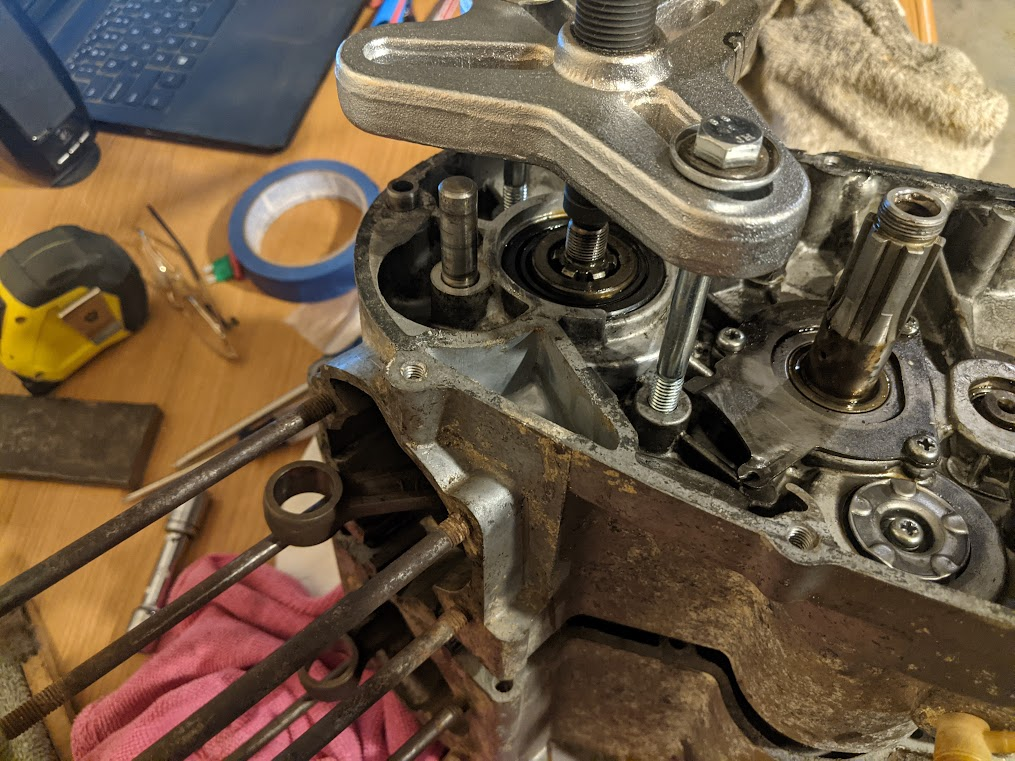

Anyways, the top end turned into a full teardown. Wasted a lot of time hunting up bits to make Yamahas special tool for splitting... when I had two full case's of pullers. Crap.

Still had to order a couple 8mm bolts long enough though.

Got 'em separated easily enough. Amazing what you can do with the right tooling.

Looked the tranny over real good. Most of the book warnings concerned the tranny and shift forks. Paid special attention there. All good.

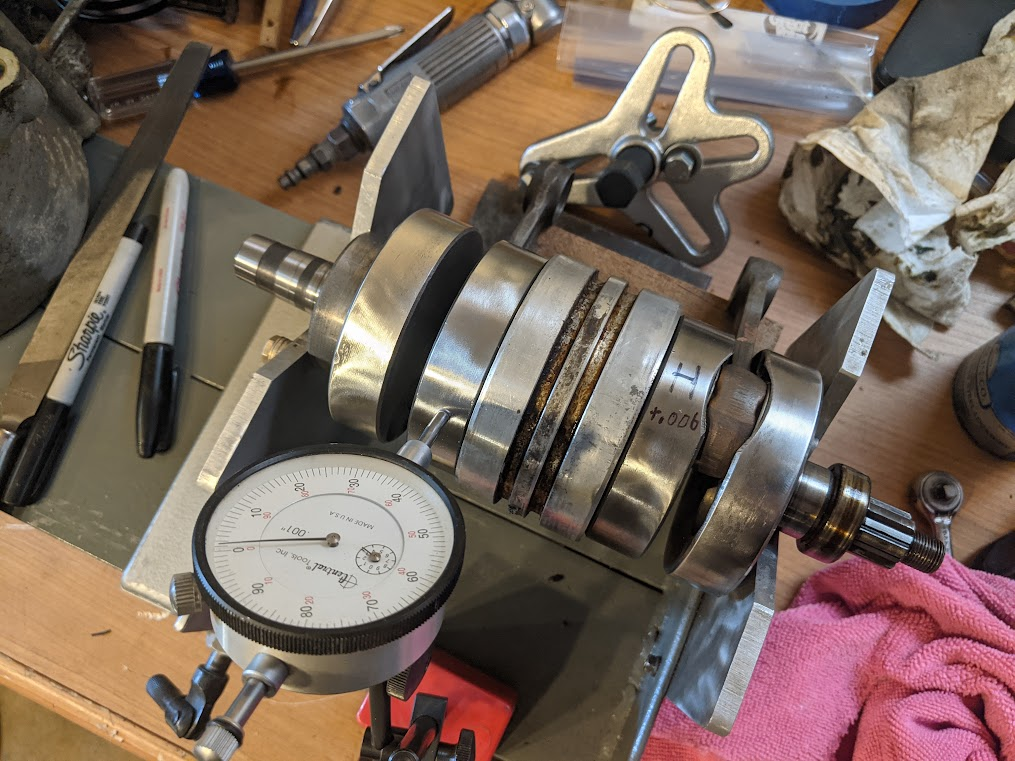

Put the crank in some V blocks.... it's bent... big time. Max runout allowed at any point is 0.0012". I'm gettin' 0.006" on one of the inner cheeks.

Crap.

Note: Cleaned up the cheeks with a blue rolok disk before measuring.

It's bent so bad that it left marks inside one of the case halves.

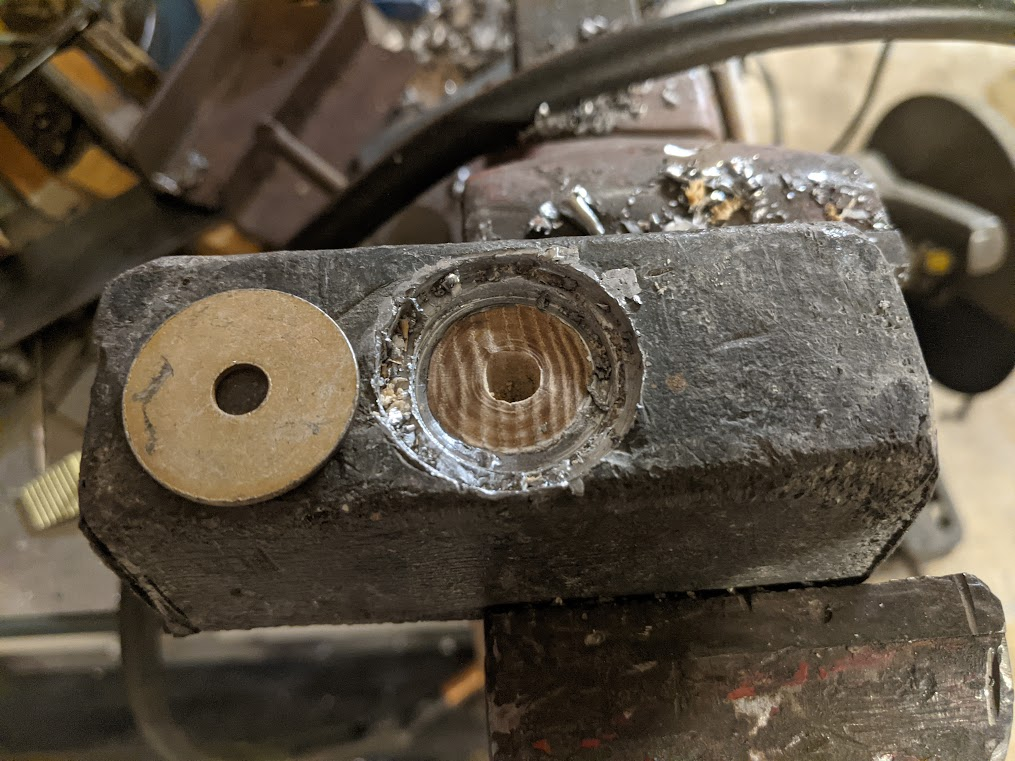

...and the right crank bearing is toast. Cleaned it again and blew it dry. It binds up so bad I can't turn it by hand.

They're still available. Fifty bucks shipped from Partzilla. Found a NOS on Ebay for $11 to my door.... sold.

So... back to that bent crank. Six thou runout sounds terrible, and it is for an installed crank. If you've ever put together a split crank though, you'll know that ain't shit. When you initially press one together you might start with double that for runout. It's just a matter of beating it straight. Seriously, that's how you do it... find out where it's bent and take a BFH to it.

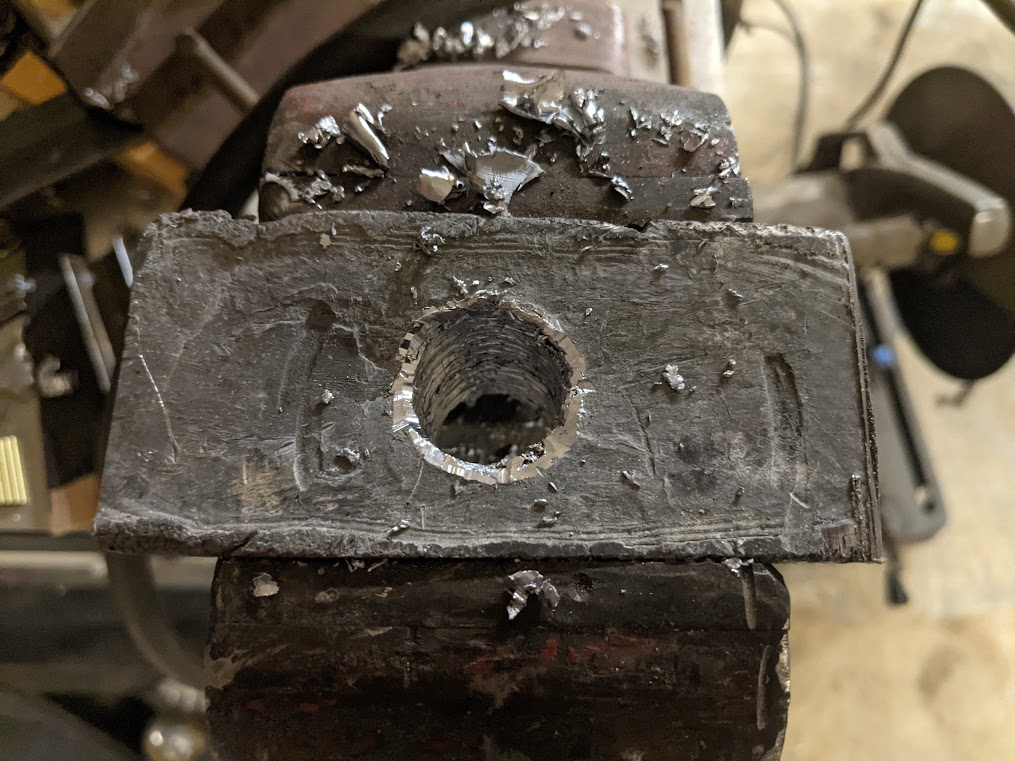

'Cept you can't use just any hammer. A steel hammer on a steel crank...

Even a brass hammer is a no go. The head of it will work harden and be almost as bad as steel. It has to be a lead hammer. One, because of the weight, and two... because lead remains malleable no matter how many times you smack it.

I used to have one, along with a nice set of wedges for spreading cheeks (insert dirty joke here .

.

That was many moons ago. Scrounged around the basement. Found a 5lb bar of lead. I even remember why I have it. Was part of a BD5 kit. It was used to balance the stabilator.

Anyway... it's a hammer now.

...and I din't turn into a mad hatter makin' it...

Anyway, I've got the worst of the runout down to 0.0005 or thereabouts. Well under the book number. Got about a week before the right main bearing shows up. Might see if I can get it down to zero.

Stay tuned...

I recall a General back in the First Gulf War, a reporter asked 'im if they had a plan. I'll overlook that he shoulda been slapped silly for that one... but the General replied "Of course we have a plan. You have to have something to deviate from."

After a good cleaning in the stoddard tank, I noticed all the sealant slopped on the case halves. Yeah... Yamaha din't slop like that at the factory. Someone's split these cases before. Bein' a vertical split case, there's tons of warnings in the book on reassembly. If you've never done a vertical split, 5 speed engine, well..... it's pretty easy to fuck one up. Crap.

And... the crank was pretty notchy trying to spin it. Yeah.... guess "notchy's" bein' kind... it was damned hard to turn by hand. Crap.

Anyways, the top end turned into a full teardown. Wasted a lot of time hunting up bits to make Yamahas special tool for splitting... when I had two full case's of pullers. Crap.

Still had to order a couple 8mm bolts long enough though.

Got 'em separated easily enough. Amazing what you can do with the right tooling.

Looked the tranny over real good. Most of the book warnings concerned the tranny and shift forks. Paid special attention there. All good.

Put the crank in some V blocks.... it's bent... big time. Max runout allowed at any point is 0.0012". I'm gettin' 0.006" on one of the inner cheeks.

Crap.

Note: Cleaned up the cheeks with a blue rolok disk before measuring.

It's bent so bad that it left marks inside one of the case halves.

...and the right crank bearing is toast. Cleaned it again and blew it dry. It binds up so bad I can't turn it by hand.

They're still available. Fifty bucks shipped from Partzilla. Found a NOS on Ebay for $11 to my door.... sold.

So... back to that bent crank. Six thou runout sounds terrible, and it is for an installed crank. If you've ever put together a split crank though, you'll know that ain't shit. When you initially press one together you might start with double that for runout. It's just a matter of beating it straight. Seriously, that's how you do it... find out where it's bent and take a BFH to it.

'Cept you can't use just any hammer. A steel hammer on a steel crank...

Even a brass hammer is a no go. The head of it will work harden and be almost as bad as steel. It has to be a lead hammer. One, because of the weight, and two... because lead remains malleable no matter how many times you smack it.

I used to have one, along with a nice set of wedges for spreading cheeks (insert dirty joke here

That was many moons ago. Scrounged around the basement. Found a 5lb bar of lead. I even remember why I have it. Was part of a BD5 kit. It was used to balance the stabilator.

Anyway... it's a hammer now.

...and I din't turn into a mad hatter makin' it...

Anyway, I've got the worst of the runout down to 0.0005 or thereabouts. Well under the book number. Got about a week before the right main bearing shows up. Might see if I can get it down to zero.

Stay tuned...

Last edited: