Laziness is the Mother of Invention

************************

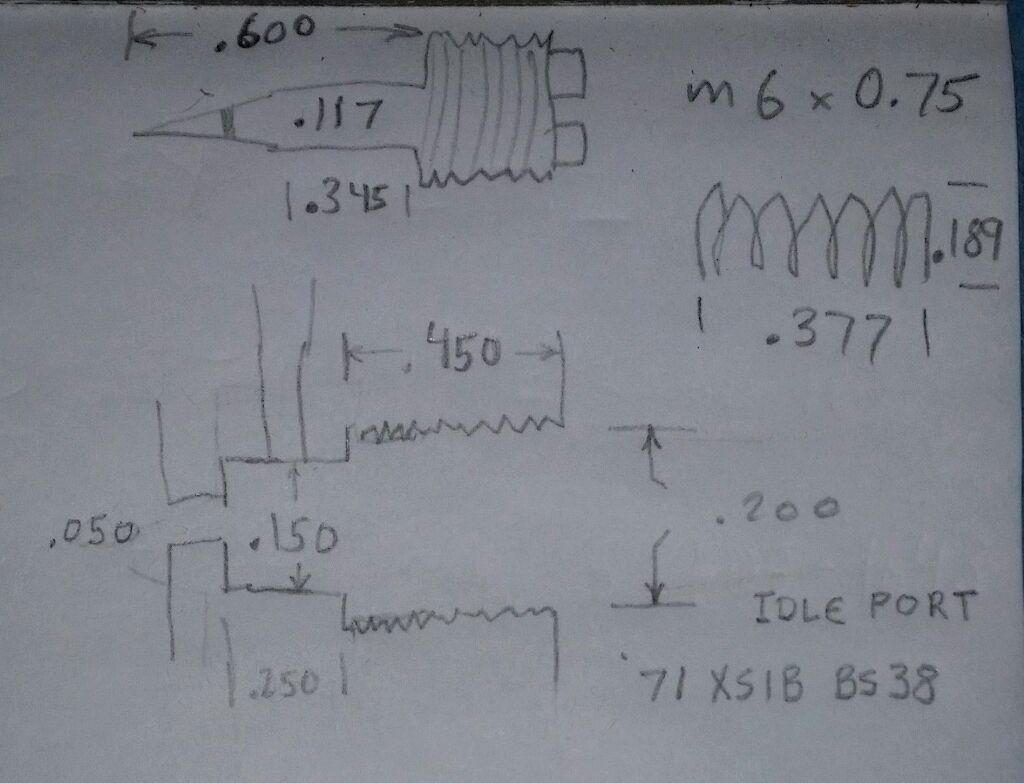

This little project works on the 70-71 XS1/XS1B carburetors.

In 1972 (XS2), the carburetor bodies were revised, but the idle fuel (mixture) screws remained the same for years 1970-1975. As such, dimensions and procedures posted here may be applicable for carburetors up to 1975. For carburetors of 1976 and later, different dimensions will need to be found.

A visit to the forum's Tech section: Carburetors may be necessary to help understand the XS650 carburetors.

Also, if you haven't done so already, download and review the "Carb Guide" for an understanding of the pilot circuit.

http://www.amckayltd.com/carbguide.pdf

************************

When the Pilot Jet (idle jet) and/or the bleed air jet becomes inadvertently clogged, an effective quick fix can be done by reverse flushing of the pilot (idle) fuel circuit.

First, remove the bowl drain plug, drain the fuel into a suitable catch container.

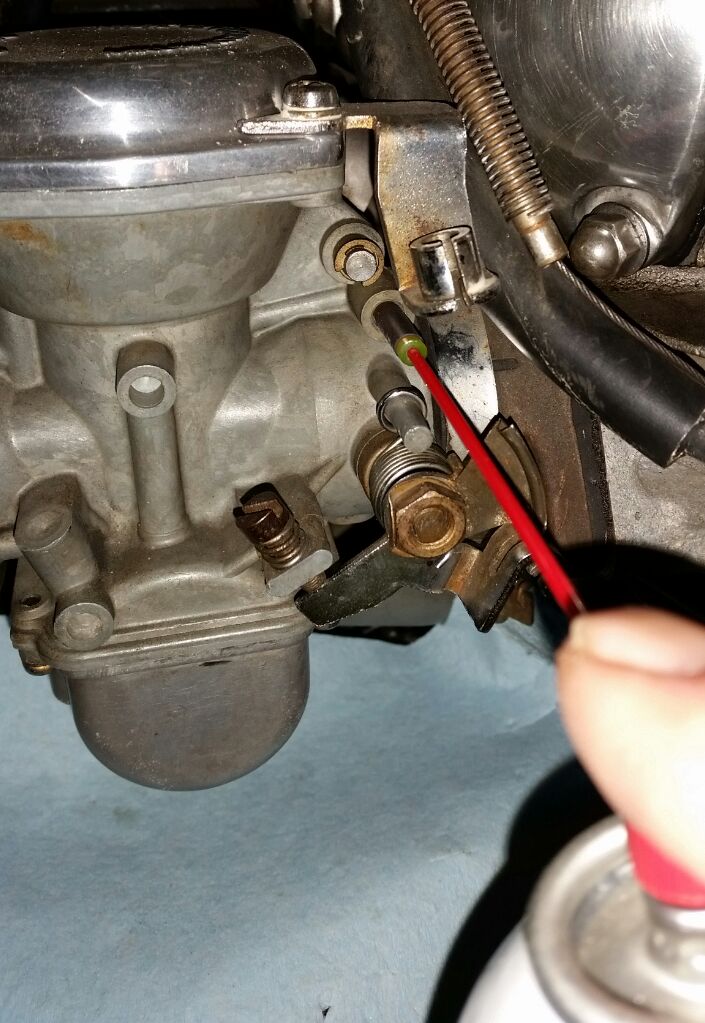

Then, remove the idle fuel (mix) screw. Insert the nozzle/tube of a can of carburetor cleaner into the port, and shoot a blast in there. The carb cleaner will spray into the pilot circuit, and hopefully dislodge any specks and contaminates back out of the pilot (idle) jet and idle air bleed jet.

The first problem with this method is that much of the carb cleaner will spray back, onto you, into your eyes, and not deliver much pressure into the fuel gallery.

One solution is to fashion a fitment to the spray nozzle/tube that seals into the idle port opening.

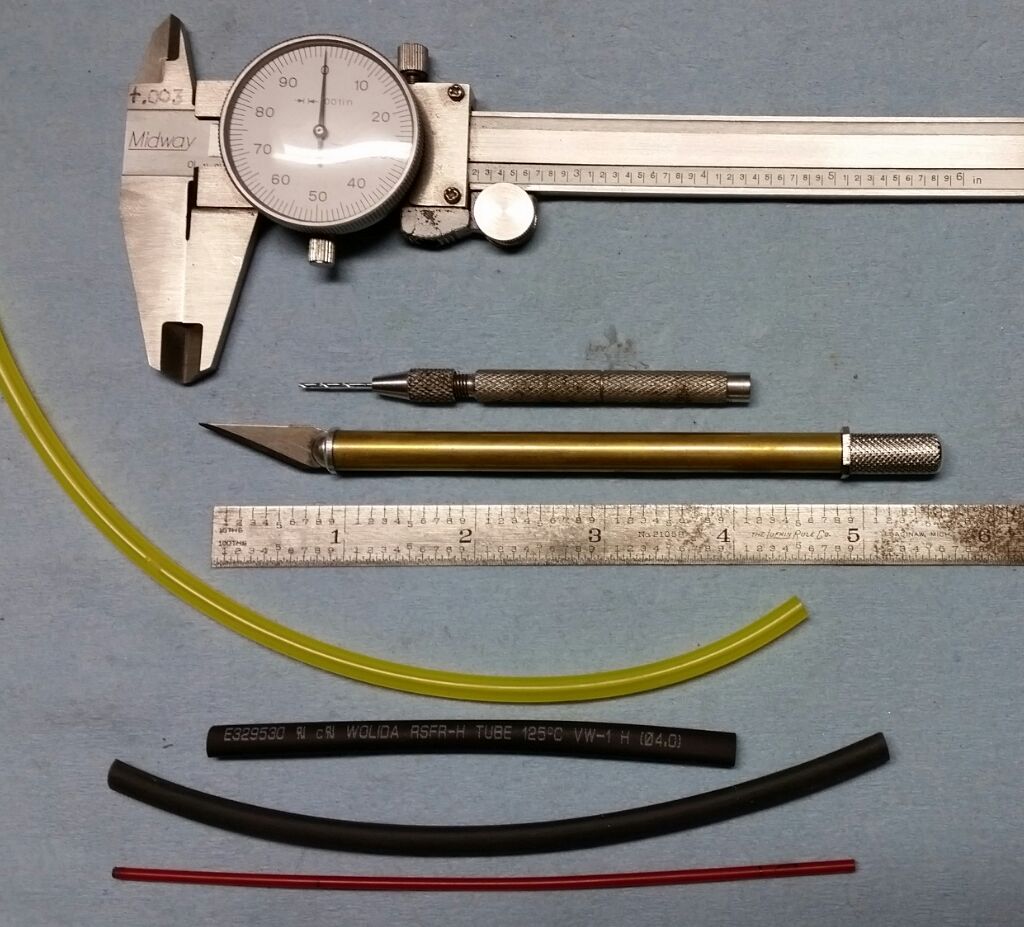

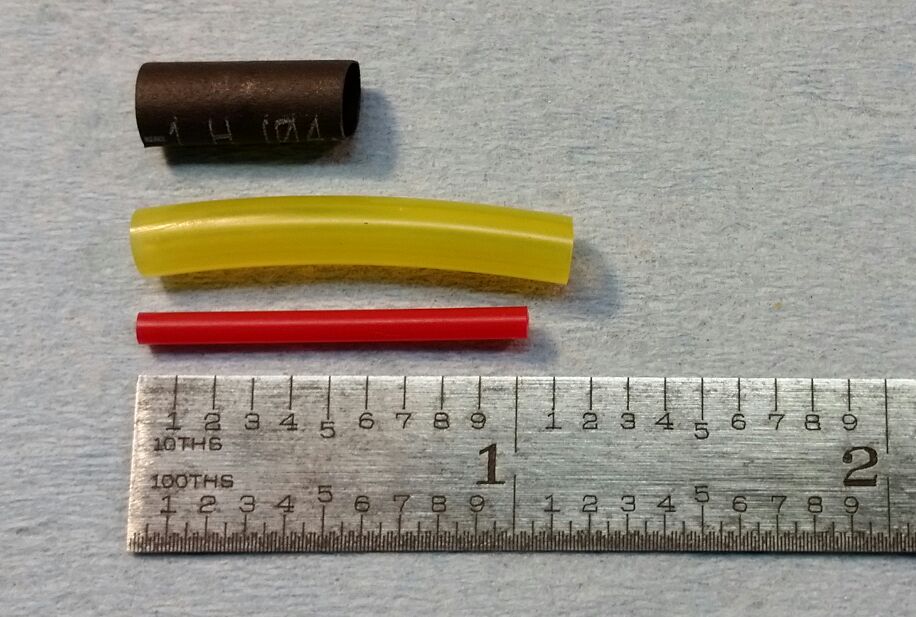

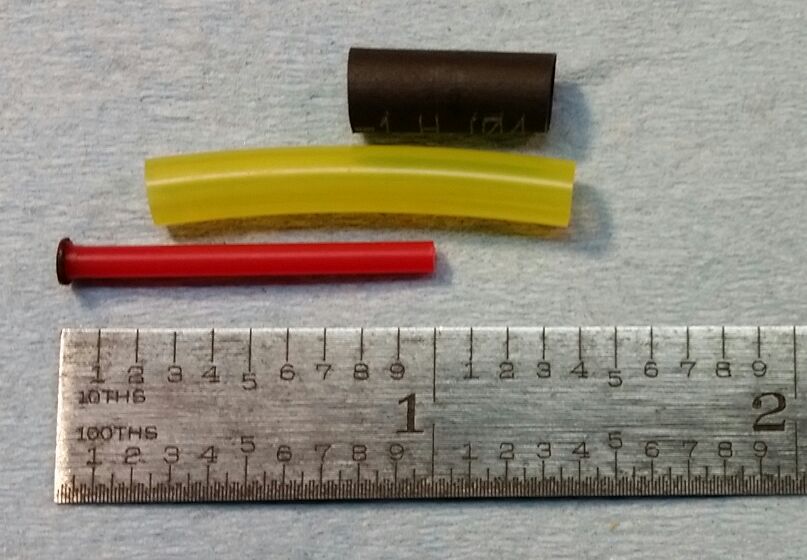

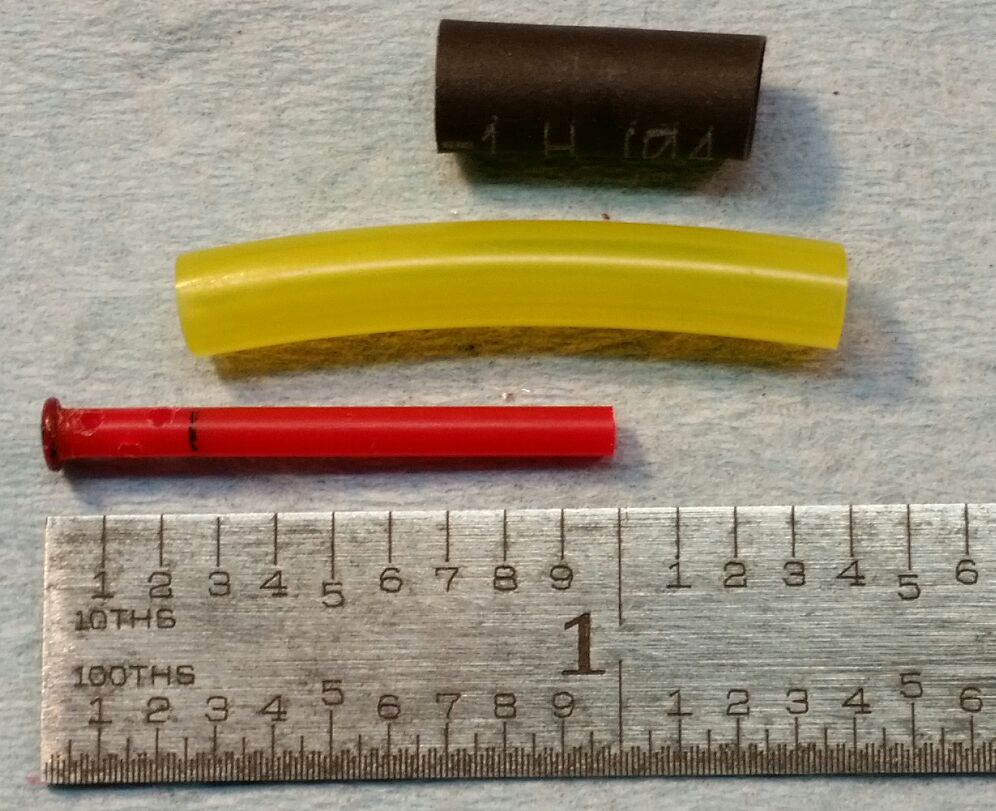

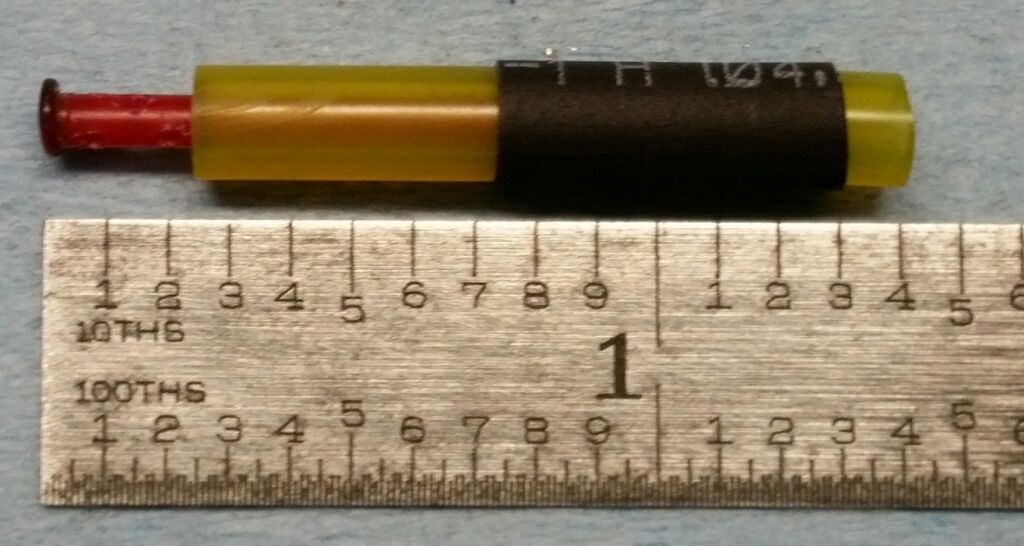

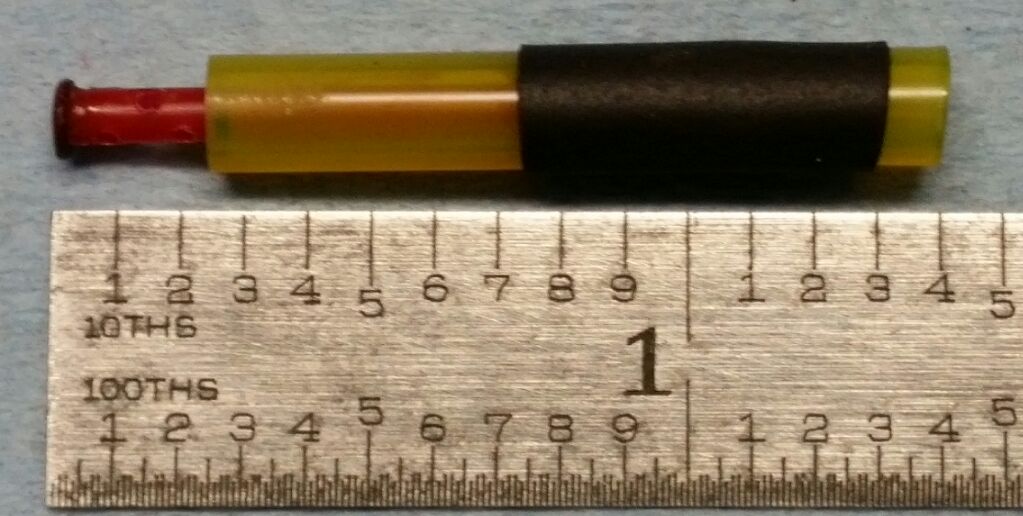

This one consists of a couple pieces of small tubing, formed like a tiny tapered cork.

************************

This little project works on the 70-71 XS1/XS1B carburetors.

In 1972 (XS2), the carburetor bodies were revised, but the idle fuel (mixture) screws remained the same for years 1970-1975. As such, dimensions and procedures posted here may be applicable for carburetors up to 1975. For carburetors of 1976 and later, different dimensions will need to be found.

A visit to the forum's Tech section: Carburetors may be necessary to help understand the XS650 carburetors.

Also, if you haven't done so already, download and review the "Carb Guide" for an understanding of the pilot circuit.

http://www.amckayltd.com/carbguide.pdf

************************

When the Pilot Jet (idle jet) and/or the bleed air jet becomes inadvertently clogged, an effective quick fix can be done by reverse flushing of the pilot (idle) fuel circuit.

First, remove the bowl drain plug, drain the fuel into a suitable catch container.

Then, remove the idle fuel (mix) screw. Insert the nozzle/tube of a can of carburetor cleaner into the port, and shoot a blast in there. The carb cleaner will spray into the pilot circuit, and hopefully dislodge any specks and contaminates back out of the pilot (idle) jet and idle air bleed jet.

The first problem with this method is that much of the carb cleaner will spray back, onto you, into your eyes, and not deliver much pressure into the fuel gallery.

One solution is to fashion a fitment to the spray nozzle/tube that seals into the idle port opening.

This one consists of a couple pieces of small tubing, formed like a tiny tapered cork.