-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

TCI Replacement 2020 It Works

- Thread starter Team Junk

- Start date

The good news is the pickup coil is the hard part of converting to Gonzo.

I’m just seeing this and catching up. This one is definitely rated:

Knowing how OEMs work, I’d guess that same little GN250 box is used on a huge number of twins in the developing world - like many many millions.

...and yes TJ - the retail price of a TCI box in Canada is in excess of $2.34 million CAD.

Also, if I’m not mistaken, the Honda MP08 coil was used on all Honda bikes with two or more cylinders for many years (ie. Gold Wings, those zillions of Honda in-line fours they sold, the ST bikes etc.).

...and yes TJ - the retail price of a TCI box in Canada is in excess of $2.34 million CAD.

Also, if I’m not mistaken, the Honda MP08 coil was used on all Honda bikes with two or more cylinders for many years (ie. Gold Wings, those zillions of Honda in-line fours they sold, the ST bikes etc.).

Last edited:

Today is forecast to be 97 and 104 down the road from me. Don't know how much I will get done today.

I really want this to work, there is probably a million GN250’s in NZ.

I really want this to work, there is probably a million GN250’s in NZ.

Same here in Ireland, I actually took my bike test on one!

Good steering lock on them made the U-Turn part of the test a cinch. The little gear indicator on them was cool too.

Just pressed together an old style rotor with a new (rewound) coil. This will be the test rotor for working out the details of adding the magnet.

Put me down for one - I've got that '81 and I don't want to rely on a 39+ year old TCI box.

P

P

I was just comparing the older alternators with the TCI versions. It looks like the older ones have sufficient space to allow for the mounting of a pickup coil? Then combine this with Jim's magnet fix.

The early stator housing are the same as the TCI stator housing. We are working out the retrofit pickup. The stock one is very shallow to fit in the space but we have a candidate that Jim should have soon. The preliminary measurements looks encouraging.

Well sumbich... that was easy.

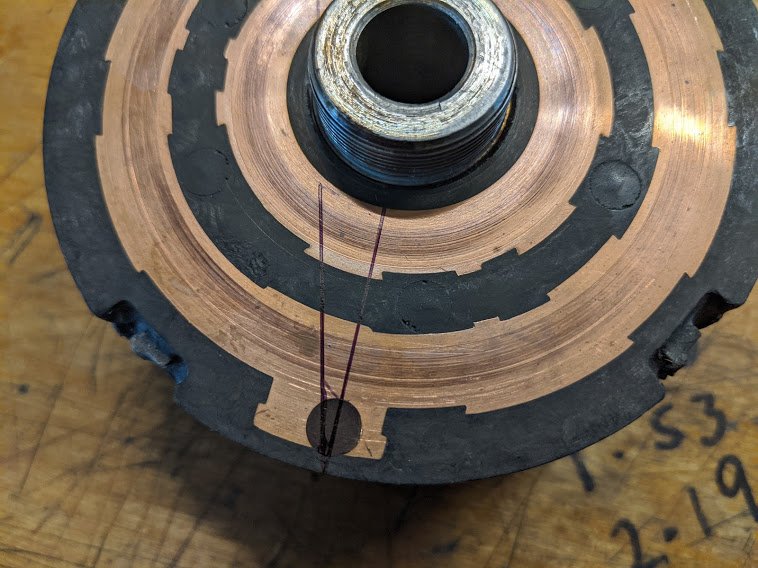

So, while waiting on the epoxy cure on the test rotor, I decided to play around with some other ones and come up with a plan. This is gonna be a pic intensive post, so bear with me... Thought about using a degree wheel, or even a digital level to figure out the angle of the magnet placement.

Both ways are pretty easy to figure out the angle... but I'm trying to stay faithful to the "backyard wrench" idea behind this whole endeavor, and not everyone has these toys. I was playing with a ruler when I noticed something.... look at the relationship between the timing mark and the magnet.

Looks to me like they line up at the edge of the mount. Looking at the edge, there's a shoulder there just below where the threads end.... enough to rest a straightedge on.

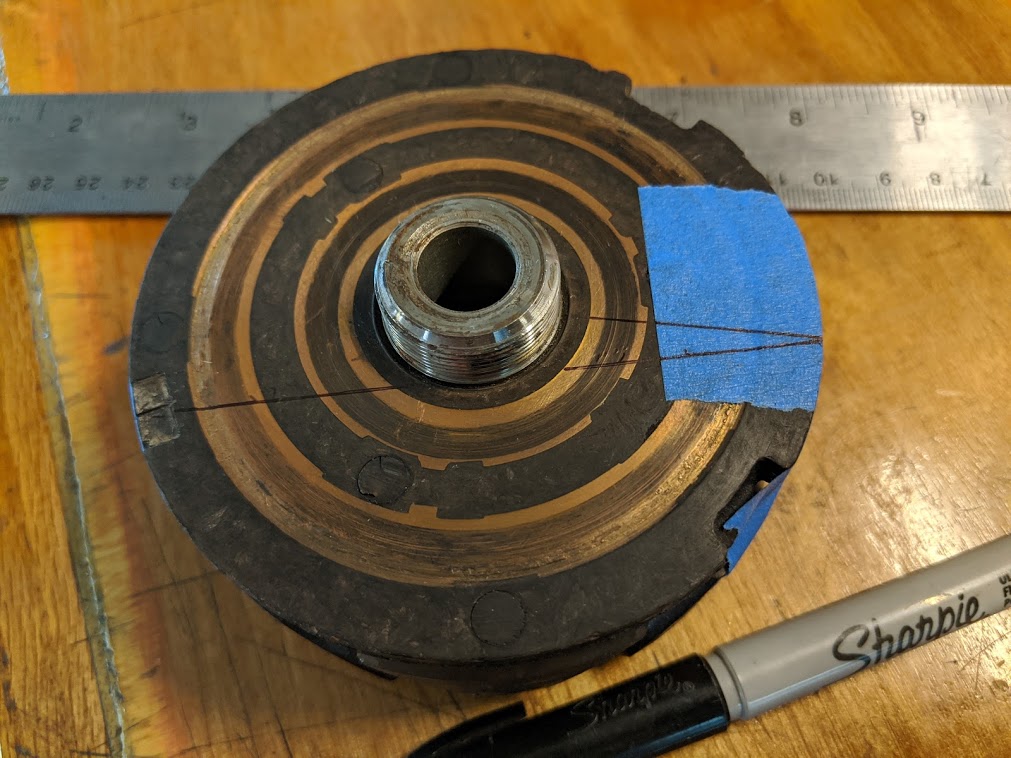

So I rested the ruler against it and lined one end up on the timing mark.

And here's where the other end wound up....

Drew a line with an ultra fine sharpie....

.... and drew a line from the edge back to the center.

Sonofagun... it splits the magnet right down the middle. So I duplicated that process on an old style rotor without the magnet.

Added some tape the the sides and ran the marks down the sides of the rotors.

Also did the same on the timing mark side of the rotors. Then I stacked 'em on each other and lined up the timing marks. Used a mirror so I could get a pic of both sides at once....

There's just a slight amount of camera parallax error there, but trust me, both sides lined up perfectly.

So... what's the correct angle? I have no idea. I'm sure my ocd will force me to find the angle at some point, but honestly... we don't need to know. It doesn't get much easier than this for the backyard wrenches out there... and that's what counts.

I'm sure my ocd will force me to find the angle at some point, but honestly... we don't need to know. It doesn't get much easier than this for the backyard wrenches out there... and that's what counts.

So, while waiting on the epoxy cure on the test rotor, I decided to play around with some other ones and come up with a plan. This is gonna be a pic intensive post, so bear with me... Thought about using a degree wheel, or even a digital level to figure out the angle of the magnet placement.

Both ways are pretty easy to figure out the angle... but I'm trying to stay faithful to the "backyard wrench" idea behind this whole endeavor, and not everyone has these toys. I was playing with a ruler when I noticed something.... look at the relationship between the timing mark and the magnet.

Looks to me like they line up at the edge of the mount. Looking at the edge, there's a shoulder there just below where the threads end.... enough to rest a straightedge on.

So I rested the ruler against it and lined one end up on the timing mark.

And here's where the other end wound up....

Drew a line with an ultra fine sharpie....

.... and drew a line from the edge back to the center.

Sonofagun... it splits the magnet right down the middle. So I duplicated that process on an old style rotor without the magnet.

Added some tape the the sides and ran the marks down the sides of the rotors.

Also did the same on the timing mark side of the rotors. Then I stacked 'em on each other and lined up the timing marks. Used a mirror so I could get a pic of both sides at once....

There's just a slight amount of camera parallax error there, but trust me, both sides lined up perfectly.

So... what's the correct angle? I have no idea.

Last edited:

Absolute brilliance Jim.

Thanks. Makes me wonder if that's how the Yamaha engineers did it. Someone just drew a line across it and said "... just put it here."Absolute brilliance Jim.

Whiz bang!

Thanks. Makes me wonder if that's how the Yamaha engineers did it. Someone just drew a line across it and said "... just put it here."

....those wacky engineers...

Beautiful. Check and make sure the keyways line up. I was reading a post somewhere here about the keyways not lining up with the timing mark maybe having to do with early vs. late.

Makes me wonder if that's how the Yamaha engineers did it. Someone just drew a line across it and said "... just put it here."

I think it was more where the pickups ending up centered in the housing.

Keyways are identical on OEM's. Repops.... not so much.Beautiful. Check and make sure the keyways line up. I was reading a post somewhere here about the keyways not lining up with the timing mark maybe having to do with early vs. late.