I seem to remember Jim trying that with his problem conversion rotor. I have that rotor and I'm working on a setup on the Gonzo dyno that will allow me to power up the rotor while spinning it so I can explore that possibility with the scope.I was thinking as a test -- experiment for those cases when problems are there as fact finding ---is the charging the source or not

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

TCI Replacement 2020 It Works

- Thread starter Team Junk

- Start date

Actually, the problem was a magnet in the rotor and a magnet in the pickup... it weren't at all happy like that. I removed the magnet from the pickup and it worked just fine with the rotor energized or not.... charging made no difference after removing the magnet.I seem to remember Jim trying that with his problem conversion rotor. I have that rotor and I'm working on a setup on the Gonzo dyno that will allow me to power up the rotor while spinning it so I can explore that possibility with the scope.

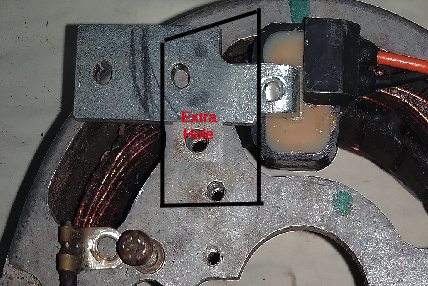

I remember that the magnet in the pickup was causing problems. One of the things I like about the rawhide pickup is it's super easy to shed the magnet. Drill 2 rivets and adios.

Concerning the one report I've seen of random sparks from the Gonzo.

The Boyer install documents mention the possibility of interference but that is due to the spark plugs 20,000 volt or better pulses occurring a inch or so from the pickup. The rotor operates at much lower voltage levels. The Gonzo requires a ~3.4 pp volt pulse on the pickup input to fire and that would be a pretty significant noise signal.

There was some discussion recently about the after market rotor having much thiner copper shielding on the face of the rotor and I wonder if that could be responsible.

The one thing I've found is the Gonzo starts to attenuate the pickup signal at around 14volts. The rawhide pickup unloaded at 2500 rpm puts out close to 30 vpp and I wonder if that mechanism is causing problems..

Thankfully the success of the Gonzo is only marred by a few problem children but they still bug me.

Jim , do you have any idea of the current draw of the rotor. I suspect that is cause of Jan's voltage drop and is normal .

Concerning the one report I've seen of random sparks from the Gonzo.

The Boyer install documents mention the possibility of interference but that is due to the spark plugs 20,000 volt or better pulses occurring a inch or so from the pickup. The rotor operates at much lower voltage levels. The Gonzo requires a ~3.4 pp volt pulse on the pickup input to fire and that would be a pretty significant noise signal.

There was some discussion recently about the after market rotor having much thiner copper shielding on the face of the rotor and I wonder if that could be responsible.

The one thing I've found is the Gonzo starts to attenuate the pickup signal at around 14volts. The rawhide pickup unloaded at 2500 rpm puts out close to 30 vpp and I wonder if that mechanism is causing problems..

Thankfully the success of the Gonzo is only marred by a few problem children but they still bug me.

Jim , do you have any idea of the current draw of the rotor. I suspect that is cause of Jan's voltage drop and is normal .

It's toughly 2.4A at full charge. When it get's hot.... 200° or so, resistance climbs to the point it's down to 2A or slightly under... I've got a videao of it around here somewhere....

Yeah, I pointed out to Jan in one thread or another that the rotor was the most likely reason for his voltage drop, and that it's most likely normal.

Yeah, I pointed out to Jan in one thread or another that the rotor was the most likely reason for his voltage drop, and that it's most likely normal.

My numbers are off a bit.... damn memory.

Misc rambling.

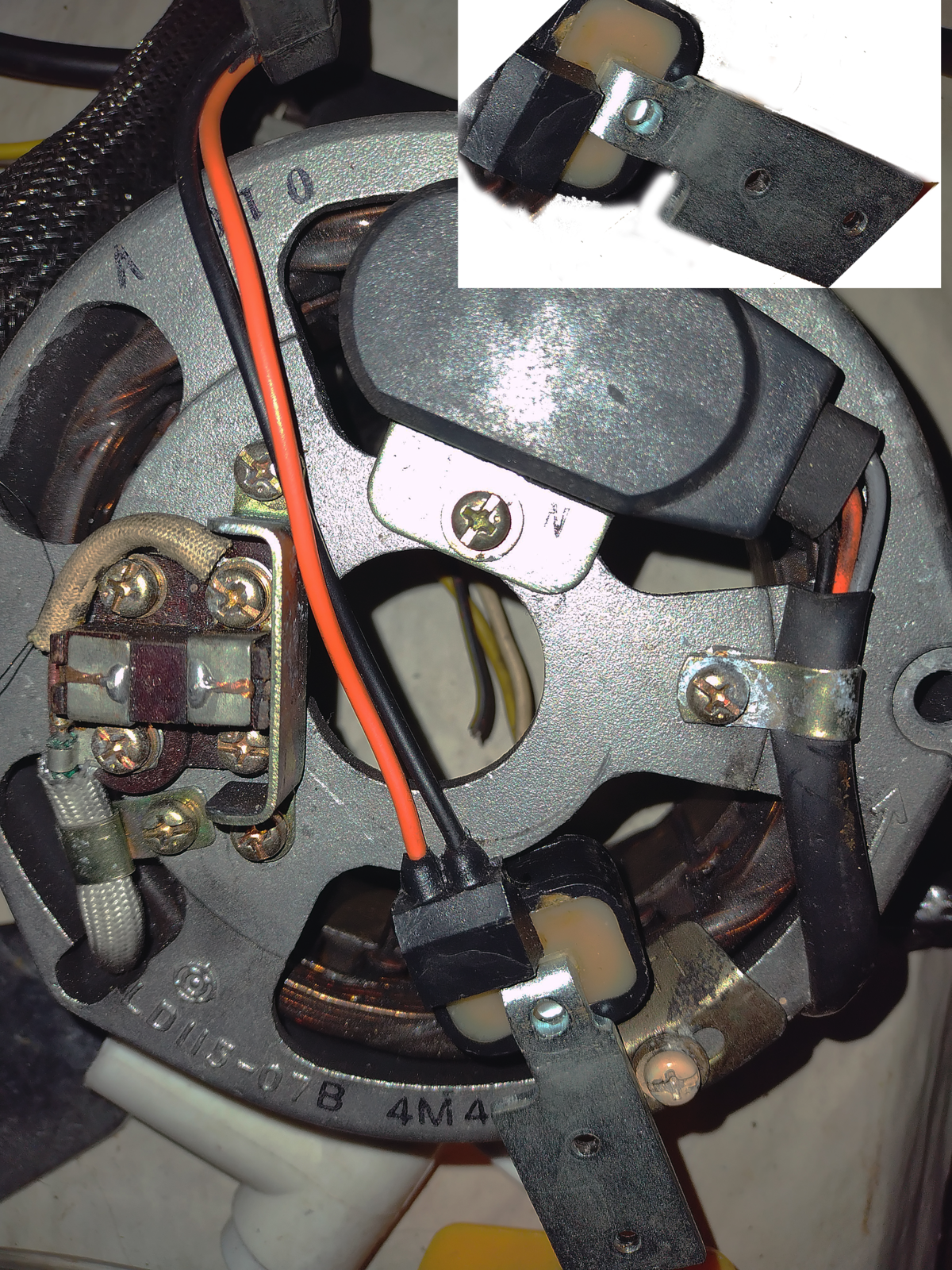

Ground clamp coil mounts. I wish I could take credit for this and sadly can't credit who did come up with the idea. Can't remember where I saw it.

Ground clamp coil mounts. I wish I could take credit for this and sadly can't credit who did come up with the idea. Can't remember where I saw it.

Attachments

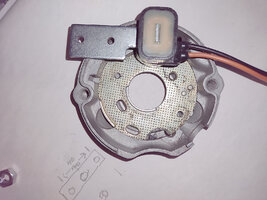

Checking flying height. the insert shows the orientation of the pick to use stock magnet location.

Some words about the rawhide pickup.

I like this pickup for a lot of reasons.

First and foremost is the similarity between the stock TCI pickup and the rawhide on the scope.

It was used on all US chrysler 6 and v8's for over a decade .

The magnet removes easily and the mount bends out to a usable shape very easily.

Dodge trucks are integral to the Texas experience and this pickup was introduced on the 1980 Dodge truck , same year as the TCI on the 650. The technology matches the era of the bike.

Can be pretty small if need be.

I like this pickup for a lot of reasons.

First and foremost is the similarity between the stock TCI pickup and the rawhide on the scope.

It was used on all US chrysler 6 and v8's for over a decade .

The magnet removes easily and the mount bends out to a usable shape very easily.

Dodge trucks are integral to the Texas experience and this pickup was introduced on the 1980 Dodge truck , same year as the TCI on the 650. The technology matches the era of the bike.

Can be pretty small if need be.

Some words about the rawhide pickup.

I like this pickup for a lot of reasons.

First and foremost is the similarity between the stock TCI pickup and the rawhide on the scope.

It was used on all US chrysler 6 and v8's for over a decade .

The magnet removes easily and the mount bends out to a usable shape very easily.

Dodge trucks are integral to the Texas experience and this pickup was introduced on the 1980 Dodge truck , same year as the TCI on the 650. The technology matches the era of the bike.

Can be pretty small if need be.

Stop it! Yer makin' my fingers itch......

Happened to stumble across this today. Saw that post many years ago and kept those parts in mind. I knew it was @kopcicle that had posted about the Mopar parts and he and I have talked about them. Years gone by and now hopefully the rawhide will be a core part in keeping these bikes running.

Thanks again Dennis. the Gonzo exists due to Your, MRRIGGS and Pete's work to get us here .

Excellent thread. Probably the genesis of the Gonzo.

https://www.xs650.com/threads/tci-box-a-successful-repair-electronic-ignition-ignitor.3289/page-5

Thanks again Dennis. the Gonzo exists due to Your, MRRIGGS and Pete's work to get us here .

Excellent thread. Probably the genesis of the Gonzo.

https://www.xs650.com/threads/tci-box-a-successful-repair-electronic-ignition-ignitor.3289/page-5

Last edited:

These 2 posts from 2014 I saw years ago and were what started me looking for a solution. Motivated by the fact I had a TCI engine but no box or wiring for the TCI I tried a XJ700 TCI box ,Honda scooter boxes etc. 8 years on the Gonzo seems to be Swiss in the middle of these posts.

Thanks guys

And 8 years later a pretty good look at where we stand on the 650 d.i.y. ignition.

Thanks guys

Kopcicle, Many thanks! Got a couple questions though: Actually, this first question applies to both the GM and Chrysler units. I'm pretty familiar with the Chrysler unit, having had 33 years in the field for Chrysler and 3 of those were in the '70s as Chrysler Field Service Rep. I've often wondered about 'converting' an automotive ECU to motorcycle use......as they are pretty reliable 'switching' devices. But, I know for a fact that there are NO advance curves built in to the Chrysler unit. The Chrysler distributor, much like the OE Crank-Based unit, simply derived it's trigger signal from a 'star' shaped device (Reluctor) having points that equaled the number of cylinders.....and as each star tip passed over the pick-up coil a signal was induced that then triggered the ECU. BUT.....the old style EI systems still relied on a mechanical/vacuum advance built into the distributor.....much like I believe the Pamco unit does using the original Yamaha Points system centrifugal advance unit. So, in adapting either the GM or Chrysler unit for use...and assuming you're still using the crank-based pick-up system....how do you account for an 'advance' program? Or, if using a different pickup with the automotive ECUs.......aside from the Pamco unit.....do you have a different method that DOES supply an advance?

I guess the other question is simply; What about other motorcycle ECUs that might be applicable......like an adaptation of a 400 or 750 2-cylinder with electronic ignition......or even a Honda, Kawasaki, or Suzuki unit that might have some similar engineering?

You mentioned Briggs & Straton; I have wondered about those myself. But, again, not sure how the programming works......and what kind of advance system is employed on some of the Briggs units. Also, wondered about the HD systems. Harley's been using 2-cylinder electronic ignitions for decades, and the number of after-market units available to 'upgrade' a HD is amazing. My HD has a unit made by Daytona called a Twin-Tec. It's quite programmable......had a cost of about $60 when I purchased it.......and it works with HD's single wind / dual fire coil.......which is a similar design to Yamaha's coil. I gotta believe that there's some potential there for adaptation.......but have heard of no one ever giving it a try. Just seems to me those are better options than attempting to re-purpose the automotive units that have the 'no-advance programming' associated with them. But.............hey, I'm a rookie at all this......so that's why I'm asking the questions. There's probably good reasons....and I'd just like to know what they are.

Tom D....... (2 cats by the tails.......lol)

You really are over thinking this from a one off standpoint . The automotive parts are available everywhere . The GM , FoMoCo , and MoPar "igniters" are under $20 in most places and the pickups sometimes as low as $10 . Add the possibility of roadside scavenging or junkyard acquisition and the availability increases and the price drops substantially . in the case of the GM for sure a bit of forward bias allows you to use points at greatly reduced voltage and current leaving the rubbing block as the only wear item . The size of the stock points setup and the HEI parts is low allowing you to carry both a spare HEI or even an extra coil with little weight , volume or complexity penalty .In short i don't know the alternatives because I never looked . I didn't have to , need to or have any desire to .

A better mouse trap ? sure I've done that . A better hammer ? Why bother ? Just get a bigger one . I'm not about to re-invent the wheel , build a bridge to throw a rope across , design , adapt an electronic ignition , or fix the national trade deficit just in the name of a programmable advance curve for a 50 year old design (century if you want to include Kettering) 40 year old motorcycle just to say "mine is bigger , better than yours AND shoots around corners" NOT gonna happen .

Two cats indeed

~kop

And 8 years later a pretty good look at where we stand on the 650 d.i.y. ignition.

There's another thread I just noted called 'Gonzo Turns One' here on this web site....... so maybe further support info there as well.

When I did my investigating in to this process I came to a couple of conclusiont: One: virtually ANY XS650 could be converted to becoming an 'electronic ignition' type bike using this Gonzo box, replacing a non-TCI rotor with a TCI rotor (one that contains the trigger magnets), and with the addition of a pickup device on the rotor frame (similar to the stock pickup). I also concluded that finding a good rotor with good magnets wasn't nearly as difficult a process as finding a good 'Stock OE' TCI box. Likewise the pickup assembly. As it works out, there are guys drilling non-TCI rotors and adding magnets, as well as guys working on developing a simple replacement pickup. So, while the costs of finding both of these parts in OE Yamaha branded units may be 'not cheap' at this point. I think down the road there will be further updates that make having a reliable and 'simple' electronic ignition system on an old vintage XS a LOT easier than some of the currently available units; IE the BB or others. My advice is to go with the Gonzo box, use a confirmed 'good' pickup and TCI rotor, and just do the easy task of wiring it all up to work. The end result will be that, just like the OE TCI box, if Gonzo box goes bad, it will be a unplug and replace repair done in minutes. Any costs to modify to this if you have an already existing TCI bike and minimal........ like just revising the TCI plug set up and mounting, and you're good to go. I'd guess 'converting' a NON-TCI bike to eliminate the old points system completely, including the mechanical advance, would take not much more than another 30 minutes over what ever it would take you to replace the rotor..... with proper tools, what? 2 hrs? Anyway.... just my opinion, and I'm stickin' to it!!!

Pinky and the Brain thought for today.

@kopcicle points out that the GM igniter would work with points . I think the gonzo will also work the same way.

Next round of gonzo tests will test. Had that in the back of my mind for a while also.

"in the case of the GM for sure a bit of forward bias allows you to use points at greatly reduced voltage and current leaving the rubbing block as the only wear item ."

@kopcicle points out that the GM igniter would work with points . I think the gonzo will also work the same way.

Next round of gonzo tests will test. Had that in the back of my mind for a while also.

"in the case of the GM for sure a bit of forward bias allows you to use points at greatly reduced voltage and current leaving the rubbing block as the only wear item ."

Edited to add that this is just a mockup. don't know if it works or not. Working on it.

Edited to add that the proper parts are in the proper hands.

Edited to add that the proper parts are in the proper hands.

Last edited:

Spent a little time in the shed today gathering up the items that will be required for the next evolution to the Gonzo cause.

Fricken 102 today with a heat index of 106. Hotter than crap in the barn. Made me think about @Jim working in the sandbox in 120 heat keeping our birds in the air. Thank you again sir.

Reminds me of when I was a kid and spent a summer working for a Cummings dealer down on the coast. Engine room temps on the shrimp boats I was working on sometimes pushed 120 degrees. We would work for 15 minutes or so and then would have to go on up deck for 20 or 30 minutes hauling our tools with us because they would become too hot to touch. Was a great motivator to go to college.

Working on being able to spin a rotor and power it up while testing to check for interference. I have a good feeling that the rawhide pickup is going to be superior to the pickups we had been trying. Mechanically it looks like the mounting will be easier and I think it has a cleaner appearance .

The cam pickup Gonzo will be the first to be looked into . 2many brought the updated magnet mount a week or to two ago and I've been doing the maths for orbit size etc. and I think it's going to work.

Hoping to get it mounted up to Ole Brown Friday morning before it get hot and see if I get spark at kick starting speed.

Fricken 102 today with a heat index of 106. Hotter than crap in the barn. Made me think about @Jim working in the sandbox in 120 heat keeping our birds in the air. Thank you again sir.

Reminds me of when I was a kid and spent a summer working for a Cummings dealer down on the coast. Engine room temps on the shrimp boats I was working on sometimes pushed 120 degrees. We would work for 15 minutes or so and then would have to go on up deck for 20 or 30 minutes hauling our tools with us because they would become too hot to touch. Was a great motivator to go to college.

Working on being able to spin a rotor and power it up while testing to check for interference. I have a good feeling that the rawhide pickup is going to be superior to the pickups we had been trying. Mechanically it looks like the mounting will be easier and I think it has a cleaner appearance .

The cam pickup Gonzo will be the first to be looked into . 2many brought the updated magnet mount a week or to two ago and I've been doing the maths for orbit size etc. and I think it's going to work.

Hoping to get it mounted up to Ole Brown Friday morning before it get hot and see if I get spark at kick starting speed.

I Believe my Boyer Bransden Dropped one cylinder when overcharging

puts out close to 30 vpp and I wonder if that mechanism is causing problems..

Thinking out loud a Zenerdiode in circuit ?? as a max limiter ??

puts out close to 30 vpp and I wonder if that mechanism is causing problems..

Thinking out loud a Zenerdiode in circuit ?? as a max limiter ??

Great story !Reminds me of when I was a kid and spent a summer working for a Cummings dealer down on the coast. Engine room temps on the shrimp boats I was working on sometimes pushed 120 degrees. We would work for 15 minutes or so and then would have to go on up deck for 20 or 30 minutes hauling our tools with us because they would become too hot to touch. Was a great motivator to go to college.

Looking forward to your continuing Gonzo experiments

.

.

Hotter than crap in the barn.

Looking forward to your continuing Gonzo experiments

Yeah! So, suck it up buttercup!