I recently made the purchase of a xs650 1980 Special II, and with it was included an extra seized engine for me to re-use parts or just use as decoration for my house.

Since I plan to do major engine work to the main bike, I have been taking the engine apart as a means to familiarize myself with the engine and design. Here are some pictures, the last one is pretty gruesome so view at your discretion!

Seems like someone needed an advance system...

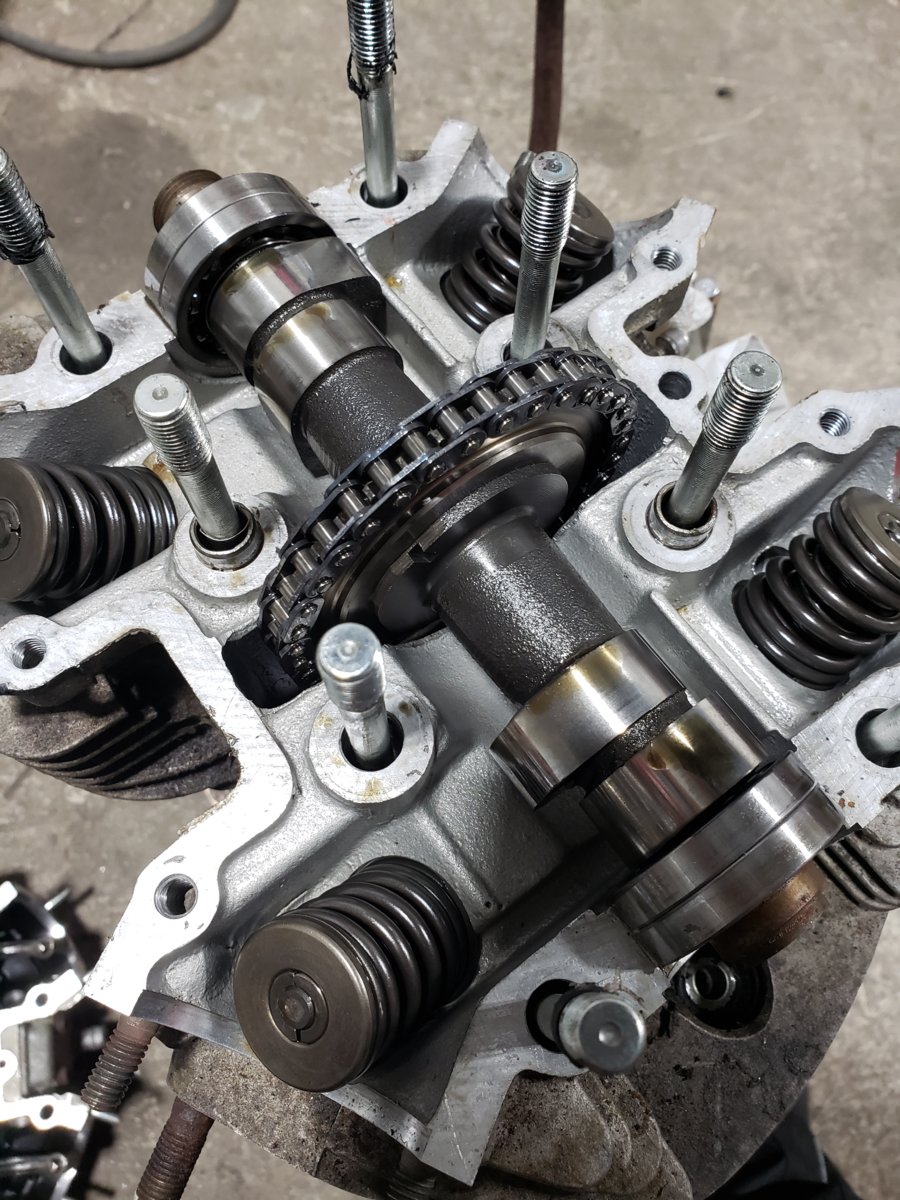

Engine was seized so I couldn't turn this to TDC. Still, it's in decent shape all things considered...

Nope it really isn't. This smelled FOUL! I would love to have any tips to clean this junk off so I can remove the jugs and continue the teardown.

Since I plan to do major engine work to the main bike, I have been taking the engine apart as a means to familiarize myself with the engine and design. Here are some pictures, the last one is pretty gruesome so view at your discretion!

Seems like someone needed an advance system...

Engine was seized so I couldn't turn this to TDC. Still, it's in decent shape all things considered...

Nope it really isn't. This smelled FOUL! I would love to have any tips to clean this junk off so I can remove the jugs and continue the teardown.