Heinz Ketchup

Wrench, Ride & Repeat

Did a rough cut on the seat pan today, bloody exciting! Can’t fucking wait to finish the bike!!

The seat will be a bit shorter than this, to match the length of the tank, but the idea is there. An exciting part is the custom seat latch works like it’s supposed to.

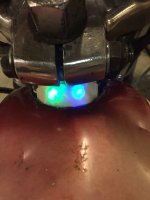

I’m out of money for now though, so the seat will have to wait a while, but hopefully it’ll be done before summer. The small things like hooking up the led controls I made, bleeding the brakes and mounting the stop light will be next, till I can afford foam, vinyl and other stuff to finish it.

My xs400 scrambler will be sold soon as well, to finance the build - In case anyone here is located in Denmark and need an extra bike, let me know

The seat will be a bit shorter than this, to match the length of the tank, but the idea is there. An exciting part is the custom seat latch works like it’s supposed to.

I’m out of money for now though, so the seat will have to wait a while, but hopefully it’ll be done before summer. The small things like hooking up the led controls I made, bleeding the brakes and mounting the stop light will be next, till I can afford foam, vinyl and other stuff to finish it.

My xs400 scrambler will be sold soon as well, to finance the build - In case anyone here is located in Denmark and need an extra bike, let me know