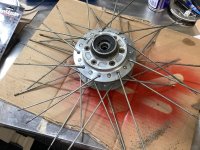

Just judging by your pics, I'd guess you have a 36-38T sprocket on there. Maybe even a 40T

Yep Jim you are correct its running a 40T rear sprocket...Yikes..

The rear wheel is 18'' with a 17T front sprocket. No wonder it felt like a Jack Hammer at 50MPH and above.

Its also running the original cheap chain as after the 40 mile run yesterday it has stretched a bit.

So I'll be putting a gold DID chain and new sprockets on pronto.