The credits for this go to @pamcopete for the original idea, Grepper @ XS650 Garage USA. for improving on Pete’s idea, and Farrel @650central for doing a comprehensive write up, I followed Farrels write up to replace the intake valve seals on my XS2. Here is a link to Farrels article.

http://www.650central.com/smoking_due_to_worn_valve_seals.htm

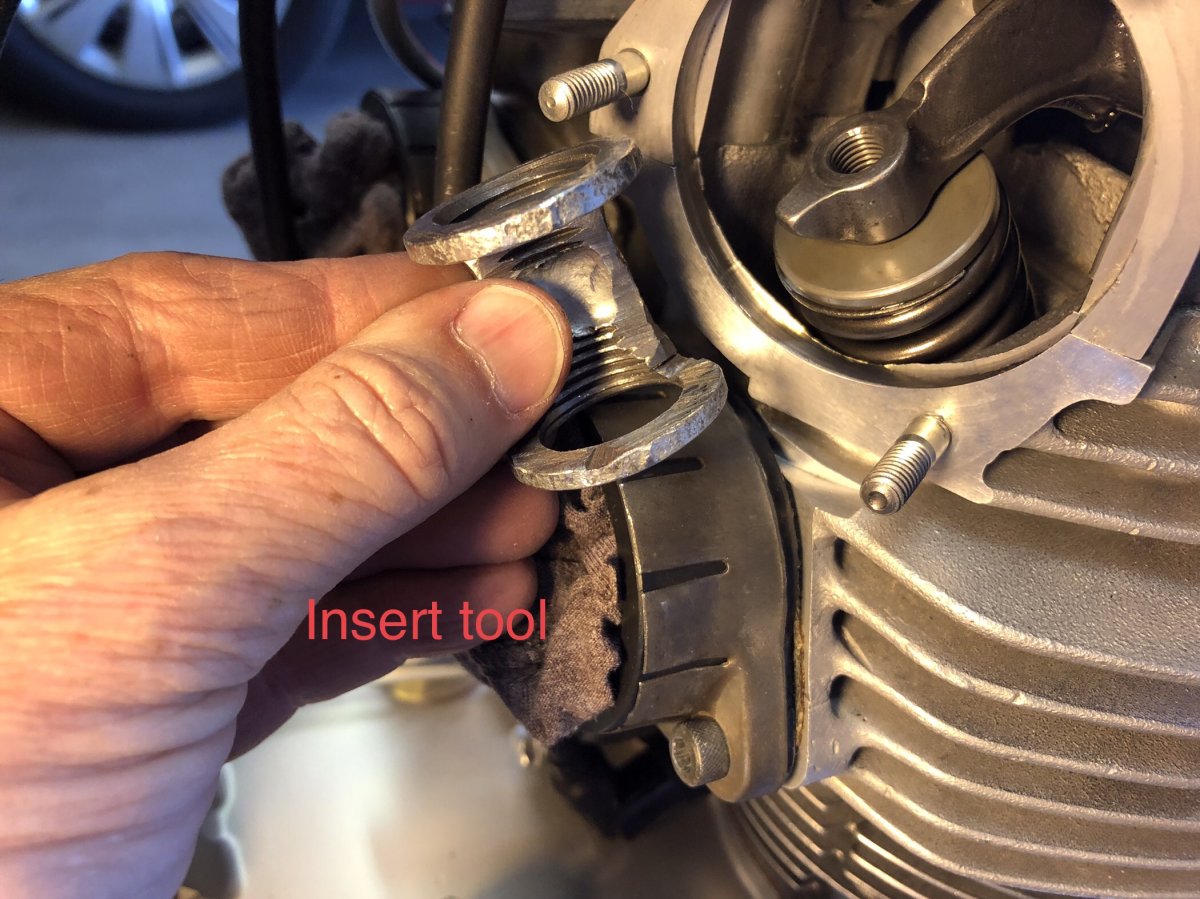

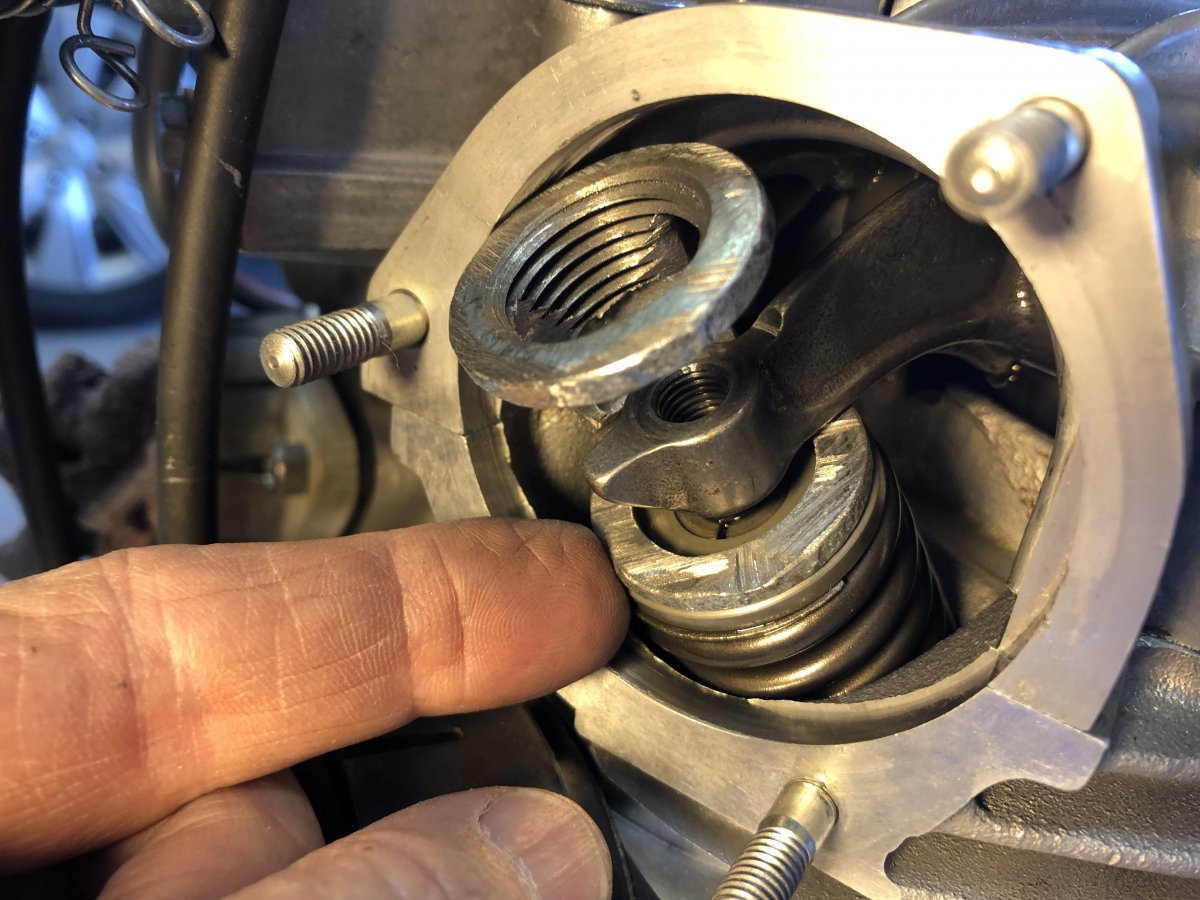

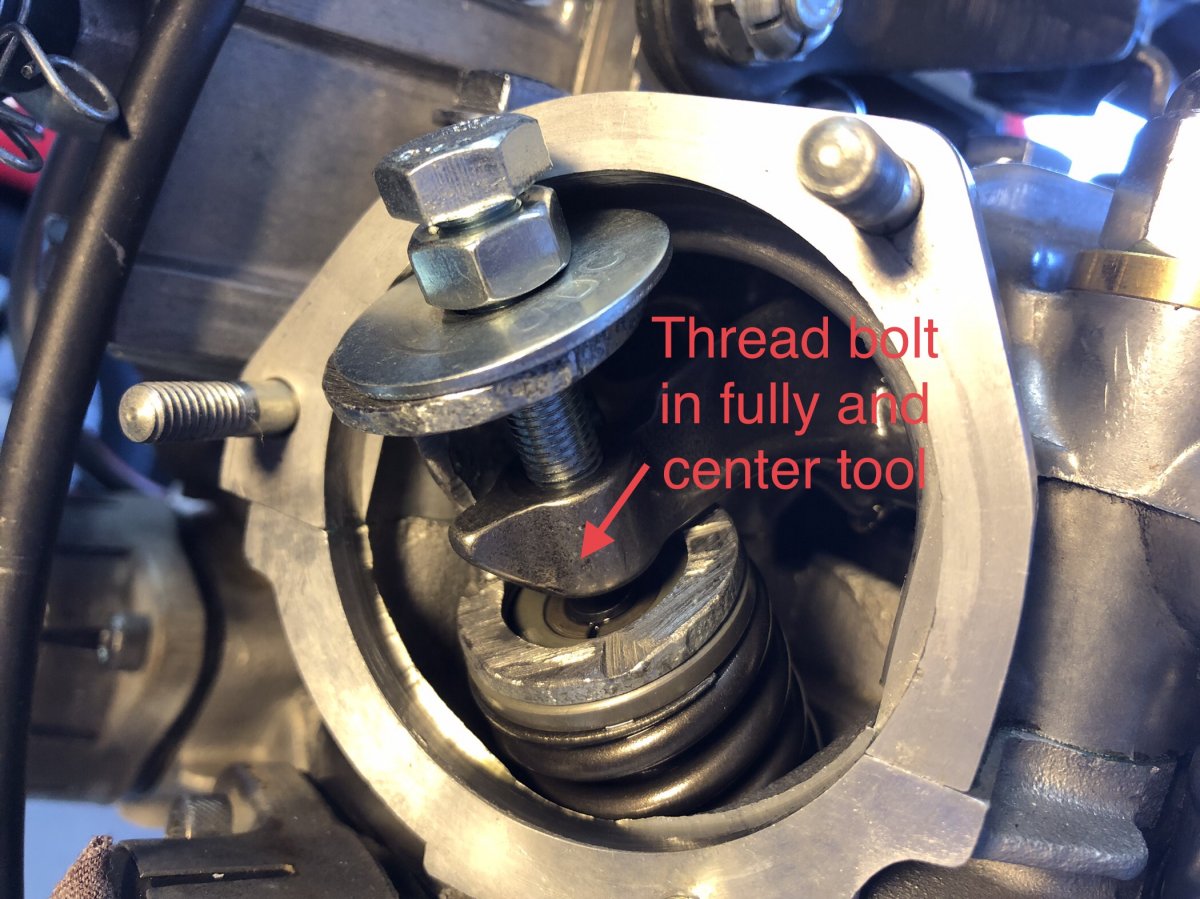

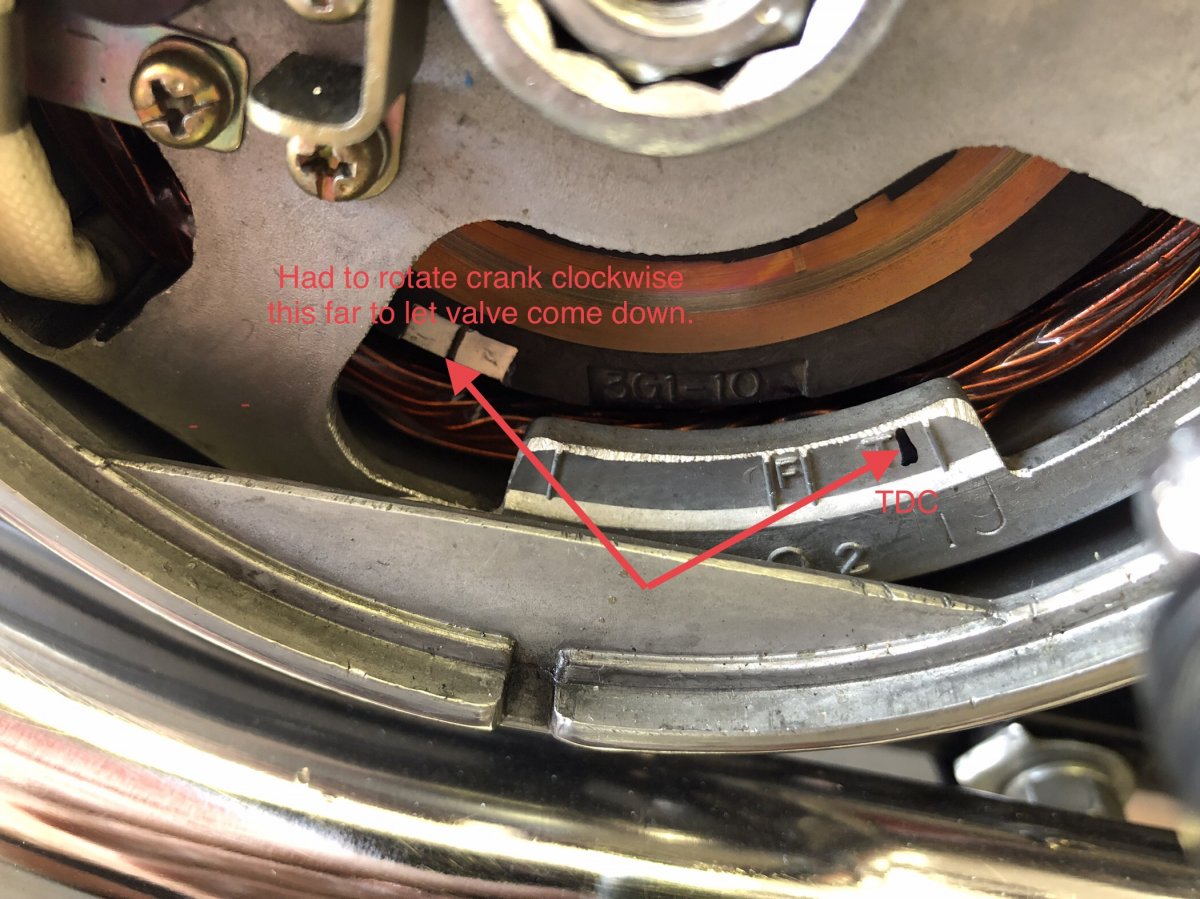

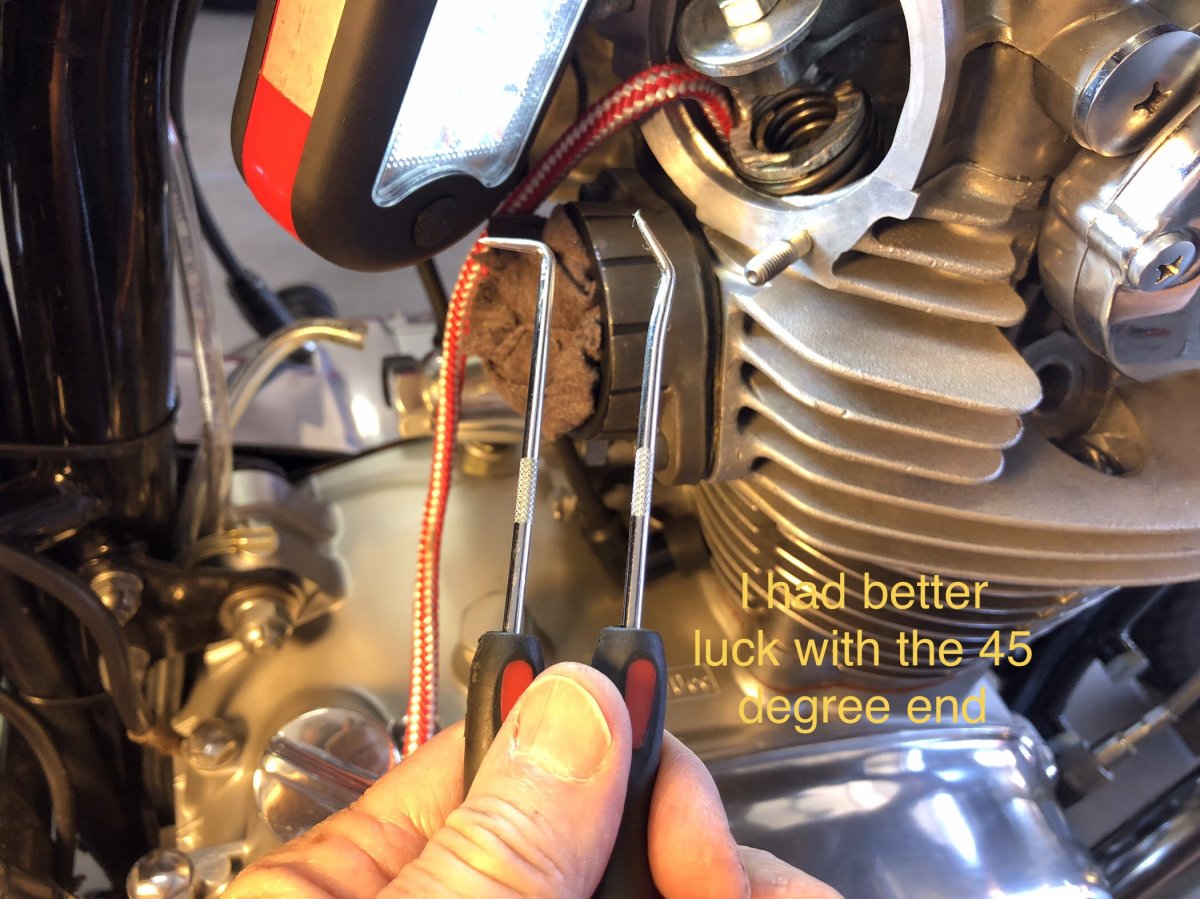

I am not looking to re write the work already done, but to try and supplement their ingenious idea with a comprehensive set of photos. It took me 90 minutes to replace and photograph the first one, I was stopping and messing with lighting and trying to take clear photos. Some aspects of the job are a bit fiddly. Nothing was overly difficult but it does require some patience. The second seal took me 45 minutes. I had been prepared to pull my motor to do this job. So without further ado…….

Part One…..

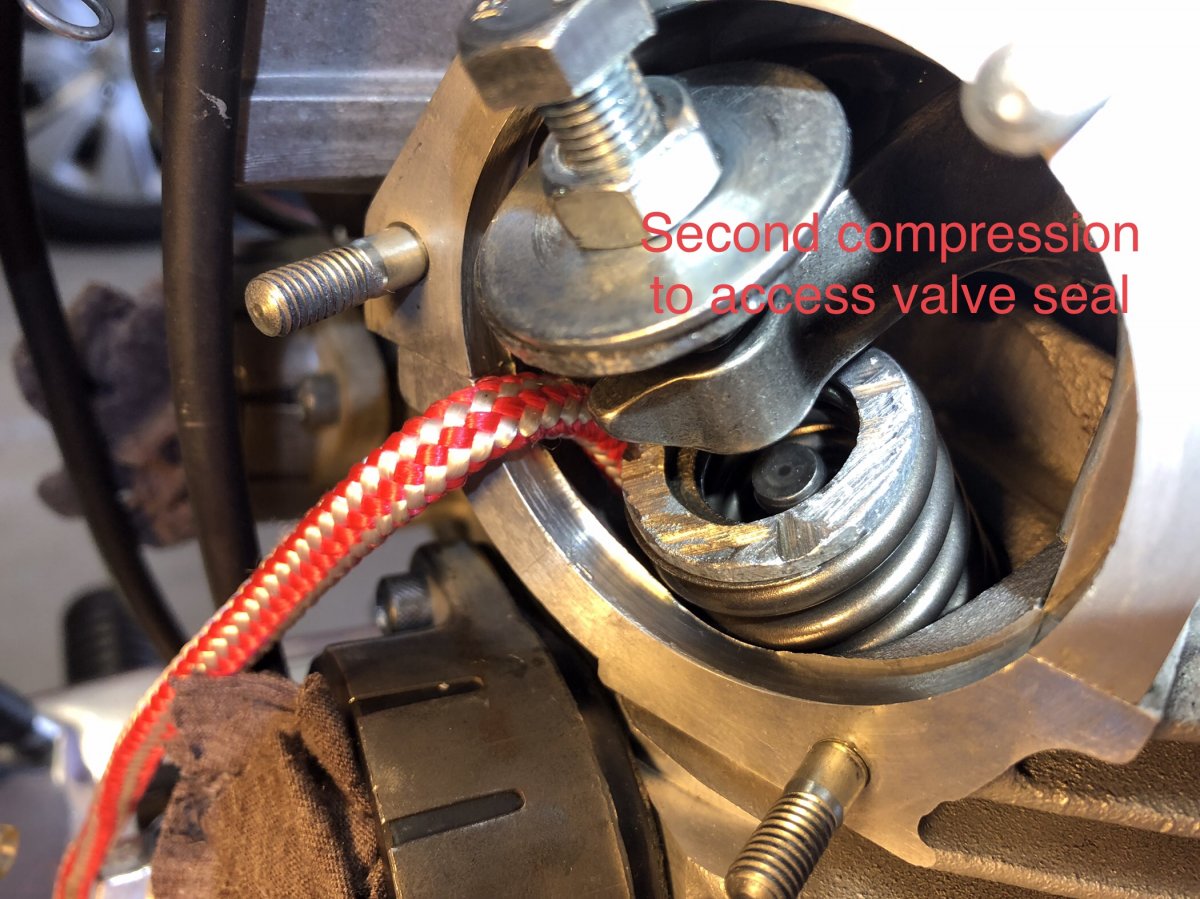

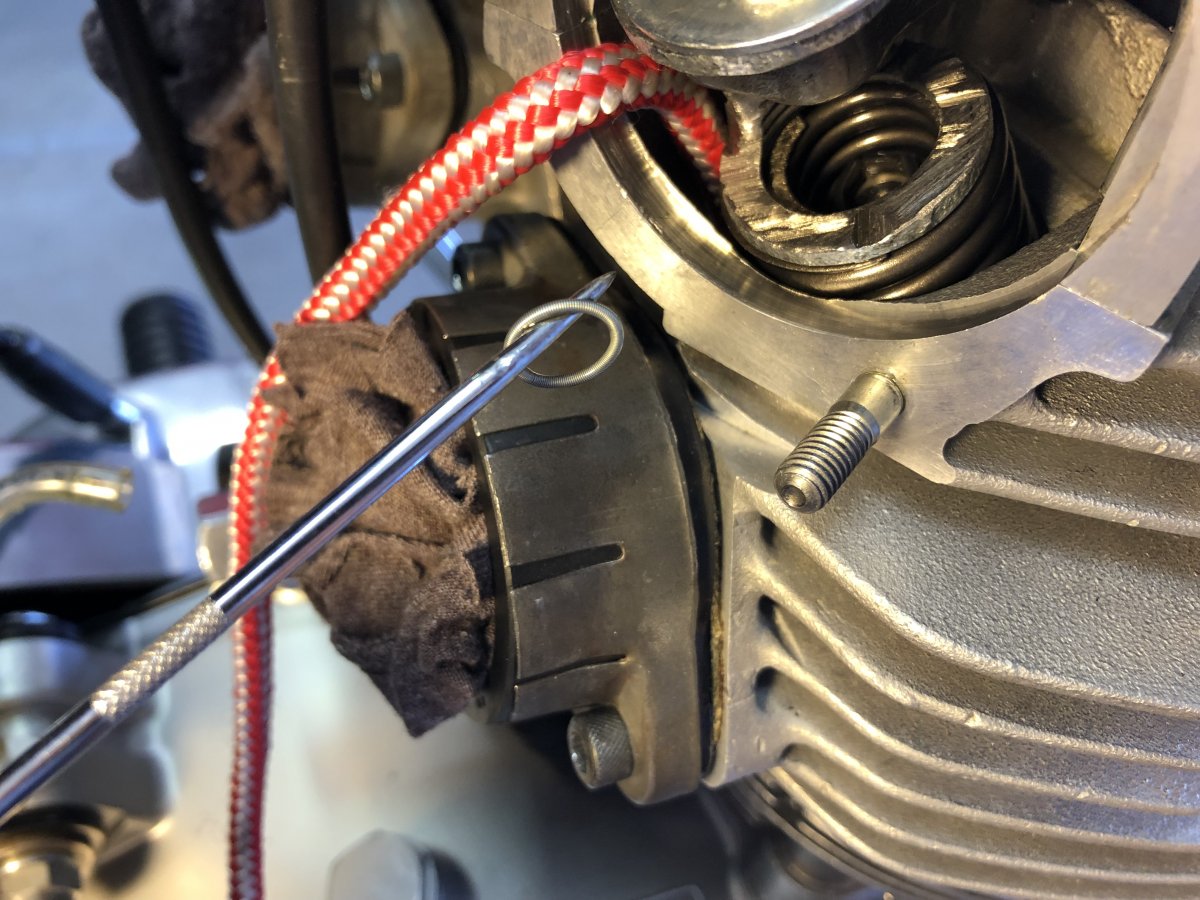

Note: the rope in this photo is shoved into an oil return passageway, in case you drop a collet, it won’t wind up in your crankcase.

Continued in Part Two…..

http://www.650central.com/smoking_due_to_worn_valve_seals.htm

I am not looking to re write the work already done, but to try and supplement their ingenious idea with a comprehensive set of photos. It took me 90 minutes to replace and photograph the first one, I was stopping and messing with lighting and trying to take clear photos. Some aspects of the job are a bit fiddly. Nothing was overly difficult but it does require some patience. The second seal took me 45 minutes. I had been prepared to pull my motor to do this job. So without further ado…….

Part One…..

Note: the rope in this photo is shoved into an oil return passageway, in case you drop a collet, it won’t wind up in your crankcase.

Continued in Part Two…..

Last edited:

Marbles Motors )

Marbles Motors )