My 88SE Virago 1000, which looks exactly like the 1100, cost £700 because it had severe cosmetic fire damage. The mileage on the engine was 2064. I would guess that something like 1500 might be the value in the UK for a bike that's not running, but depends on condition. In the US the price would be much lower, probably less than $1000 even if in good cosmetic condition. Check Ebay prices for sold items in your area.

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Virago XV1000 Carburetor Tuning.

- Thread starter Paul Sutton

- Start date

I am currently working on my Hitachi carburetors. Although I have solved the issues with the right carb some issues still remain with the left:

1. Using a Gunson Colortune plug I have found the left carb cannot be forced into a rich condition using the pilot screw.

2. Using a Carbon Monoxide probe I have found the CO level to be independent of the left carb's pilot screw settings.

My conclusion is a partial blockage in the pilot circuit. By injecting petrol into the pilot jet I have confirmed there to be greater resistance on the Left carb compared to the right.

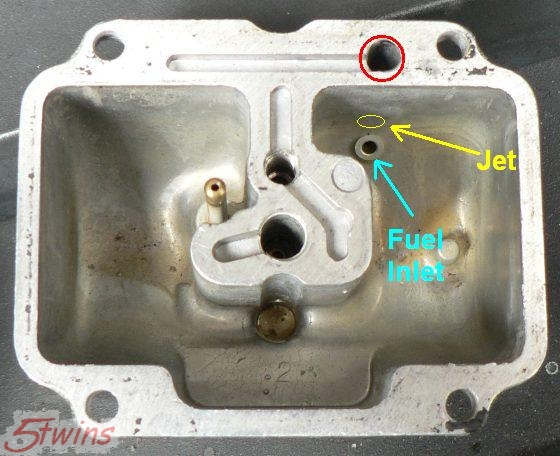

Below is a photo showing the jet position:

The pilot jet was initially blocked but has now been cleared. The actual jet is at the top of the brass tube where it meets the carb body. I assume there is a set of emulsion holes above the jet within the carb body. It is my feeling the remaining blockage lies between the pilot jet and the pilot screw (large brass housing to the far left). The route from the pilot jet to the pilot air jet is confirmed clear.

I have spent much time flushing the pilot circuit with petrol or hot soapy water. I have also put the carb in the ultra-sonic bath but still the left carb shows greater resistance compared to the right. How do I get into the pilot circuit to clear the stubborn gunk? It would be nice to remove the pilot jet but it is of the non-removeable type. There are UTube vids showing how to removed this type of jet on other carbs but has anyone had experience on the Hitachi carb??? I am reluctant to try the removal but may have to.

Thank you for any suggestions.

1. Using a Gunson Colortune plug I have found the left carb cannot be forced into a rich condition using the pilot screw.

2. Using a Carbon Monoxide probe I have found the CO level to be independent of the left carb's pilot screw settings.

My conclusion is a partial blockage in the pilot circuit. By injecting petrol into the pilot jet I have confirmed there to be greater resistance on the Left carb compared to the right.

Below is a photo showing the jet position:

The pilot jet was initially blocked but has now been cleared. The actual jet is at the top of the brass tube where it meets the carb body. I assume there is a set of emulsion holes above the jet within the carb body. It is my feeling the remaining blockage lies between the pilot jet and the pilot screw (large brass housing to the far left). The route from the pilot jet to the pilot air jet is confirmed clear.

I have spent much time flushing the pilot circuit with petrol or hot soapy water. I have also put the carb in the ultra-sonic bath but still the left carb shows greater resistance compared to the right. How do I get into the pilot circuit to clear the stubborn gunk? It would be nice to remove the pilot jet but it is of the non-removeable type. There are UTube vids showing how to removed this type of jet on other carbs but has anyone had experience on the Hitachi carb??? I am reluctant to try the removal but may have to.

Thank you for any suggestions.

I don't often show this pic. It's blown up.I am currently working on my Hitachi carburetors. Although I have solved the issues with the right carb some issues still remain with the left:

1. Using a Gunson Colortune plug I have found the left carb cannot be forced into a rich condition using the pilot screw.

2. Using a Carbon Monoxide probe I have found the CO level to be independent of the left carb's pilot screw settings.

My conclusion is a partial blockage in the pilot circuit. By injecting petrol into the pilot jet I have confirmed there to be greater resistance on the Left carb compared to the right.

Below is a photo showing the jet position:

View attachment 235858

The pilot jet was initially blocked but has now been cleared. The actual jet is at the top of the brass tube where it meets the carb body. I assume there is a set of emulsion holes above the jet within the carb body. It is my feeling the remaining blockage lies between the pilot jet and the pilot screw (large brass housing to the far left). The route from the pilot jet to the pilot air jet is confirmed clear.

I have spent much time flushing the pilot circuit with petrol or hot soapy water. I have also put the carb in the ultra-sonic bath but still the left carb shows greater resistance compared to the right. How do I get into the pilot circuit to clear the stubborn gunk? It would be nice to remove the pilot jet but it is of the non-removeable type. There are UTube vids showing how to removed this type of jet on other carbs but has anyone had experience on the Hitachi carb??? I am reluctant to try the removal but may have to.

Thank you for any suggestions.

The wire on the left is a bit of stainless safety wire with the end sharpened by hand spinning it against a fine grinder wheel. It allows probing of very small jets in deep holes. BUT being stainless, if you are too aggressive, you can ream the soft brass jet oversize. Note how deep your wire will go into the clean jet without forcing it, then go no deeper on the clogged side.

Often a tiny bit of grit gets wedged against/into a fine jet, any extraction, removal has to come from the direction AGAINST the normal fuel flow. And that's prolly the side you can't get to with a probe. @TwoManyXS1Bs made a little idle screw replacement tool to back blow with spray carb cleaner for this situation. Hah, I found it! https://www.xs650.com/threads/rever...bs38-carburetor-pilot-circuit-idle-jet.42002/

Tool tip; second bent tip wire, for hooking idle mix o-ring and washer out of the hole. Make the bend, THEN clip the off the end close. The other tools made by grinding features on the end of stainless strips from used up windshield wiper blades. Used for cleaning grooves, scraping removing gaskets, hooking out o-rings etc.

Last edited:

I agree with your assessment of the LH pilot circuit - and the CO confirms it.I have also put the carb in the ultra-sonic bath but still the left carb shows greater resistance compared to the right. How do I get into the pilot circuit to clear the stubborn gunk?

Hopefully gggGary's probe method will work. If the ultrasonic cleaner is "in-house", I might be tempted to give it another go (or two). I've had some success that way using Simple Green Aircraft & distilled water 1:2 (some use it straight), 40minutes @ 40C

The next effort could be finding a twist drill bit that snugly slides in the good RH pilot and use that to ream the LH.

Of course, removal would be fiddly, risky and a last resort.

wanted to repeat that cooltool that 2many design/built.@TwoManyXS1Bs made a little idle screw replacement tool to back blow with spray carb cleaner for this situation. Hah, I found it! https://www.xs650.com/threads/rever...bs38-carburetor-pilot-circuit-idle-jet.42002/

I've opened many a clogged removable pilot jet by back probing with a single strand from a piece of motorcycle copper wire. It's soft so won't harm the brass jet but it also wants to bend instead of forcing out a stuck bit of crap.

Serve yourself a heaping portion of patience before doing this kind of work.

Thank you Guys.

I think time and cursing is what's needed. Can anyone offer me some effective words? I have made some jet cleaners using Silver wire and the jets are all clear. I noticed the jet sizes are related to standard wire gauges so bought some Silver wire on Ebay. As for the ultra-sonics, I will try a few more hours and a variety of cleaners very concentrated. I will try to seal in carb cleaner between the pilot screw and pilot jet then ultra-sound it for a bit. I may also be able to adapt the 2M ideas to back flush the pilot circuit followed with a good bout of cursing. If only the jets were removeable...

Off to remove the carbs again... I am now a Black Belt at Virago carburetor removal, takes no more than 15 minutes.

I am now a Black Belt at Virago carburetor removal, takes no more than 15 minutes.

Note: I made a small soda blaster a while back. Had success with the bicarbonate slurried in water. Perhaps I could attempt blasting this slurry through the circuit from the air jet end. The air jet is huge approx 1.5mm.

I think time and cursing is what's needed. Can anyone offer me some effective words? I have made some jet cleaners using Silver wire and the jets are all clear. I noticed the jet sizes are related to standard wire gauges so bought some Silver wire on Ebay. As for the ultra-sonics, I will try a few more hours and a variety of cleaners very concentrated. I will try to seal in carb cleaner between the pilot screw and pilot jet then ultra-sound it for a bit. I may also be able to adapt the 2M ideas to back flush the pilot circuit followed with a good bout of cursing. If only the jets were removeable...

Off to remove the carbs again...

I am now a Black Belt at Virago carburetor removal, takes no more than 15 minutes.

I am now a Black Belt at Virago carburetor removal, takes no more than 15 minutes.Note: I made a small soda blaster a while back. Had success with the bicarbonate slurried in water. Perhaps I could attempt blasting this slurry through the circuit from the air jet end. The air jet is huge approx 1.5mm.

G#@D%^*(M)^$@!~F+*)_!nSo^ofaB*#$Fu*+erCan anyone offer me some effective words?

"Take you to the crusher"

Jan-P, good idea. I have plugged the pilot circuit and filled it with an aggressive paint thinner (Hammerite). I will leave this to soak overnight and see what gives tomorrow...

As you indicated in your post, several days soaking may be necessary. If only I still had some Dimethylsulfoxide, this will shift the spots off a Leopard.

As you indicated in your post, several days soaking may be necessary. If only I still had some Dimethylsulfoxide, this will shift the spots off a Leopard.

Not good at carburetors but there exists special Carburetor cleaner chemicals

I bought something like that .But have not used it

I generally try to avoid chemicals but if one have to so be it

Some chemical formula experts have thought it out Sometimes they get it right.

.Starting with short time and gradually increase Trying to avoid getting it on soft brass plastic or rubber parts

I had one float bowl with De greaser edit come to think of it is called " White spirit " in English i had in there

in it for weeks Probably could have used stronger chemical.

I bought something like that .But have not used it

I generally try to avoid chemicals but if one have to so be it

Some chemical formula experts have thought it out Sometimes they get it right.

.Starting with short time and gradually increase Trying to avoid getting it on soft brass plastic or rubber parts

I had one float bowl with De greaser edit come to think of it is called " White spirit " in English i had in there

in it for weeks Probably could have used stronger chemical.

Last edited:

Boil them 4 hours in phosphoric acid, you'll have a nice handful of shiny clean brass bits (and nothing else)

Spent today trying in vain. Thinking my language may be too polite I moved to the kitchen for help from my dear wife...

The words sure were flying about but still no improvement. I believe I have flogged this dead horse too long now. I may buy an old carb body from Ebay and see if things improve.

Note: For those keenly observant eyes, the brand name on the pink kettle is SMEG.

The words sure were flying about but still no improvement. I believe I have flogged this dead horse too long now. I may buy an old carb body from Ebay and see if things improve.

Note: For those keenly observant eyes, the brand name on the pink kettle is SMEG.

I have some memory of using a single strand of wire from 18ga or 16ga (1mm2)wire (2M, gggGary method) so that's gonna be about .015"(18ga) to .020" (16ga). That would correspond to a #78 drill bit (.016") or a #76 (.020"). Might be used as a reamer?? - not much downside at this point....

The big issue is the suspect blockage area lies between two non-removeable jets (0.41mm) and two 90 Degree bends. Hence the difficulty to ream out any crap. Has anyone had experience removing non-removeable pilot jets on Hitachi carburetors?

I have bought a cheapish Hitachi bare carb body just to test if the blockage is real, or in my mind?? Perhaps the flow resistance is typically higher in the left carbs. This should arrive Thurs or Friday so back to my model stationary steam engine - Stuart 10V.

I have bought a cheapish Hitachi bare carb body just to test if the blockage is real, or in my mind?? Perhaps the flow resistance is typically higher in the left carbs. This should arrive Thurs or Friday so back to my model stationary steam engine - Stuart 10V.

Bicycle pump Not sure if you can use it.In your case.

I did try the Carburetor Cleaner as in # 51

There is a straw that helps

I was cleaning the float bowl -- Red ring Put the Bicycle valve with the rubber folded so it made a seal

at the top ..And then with the cleaning fluid inside .. With some quick bumps on the pump got things moving.

Kept on .And I Now have light coming through.

I did try the Carburetor Cleaner as in # 51

There is a straw that helps

I was cleaning the float bowl -- Red ring Put the Bicycle valve with the rubber folded so it made a seal

at the top ..And then with the cleaning fluid inside .. With some quick bumps on the pump got things moving.

Kept on .And I Now have light coming through.

I will proceed with more vigor when the carb body arrives. May try and see if I can get a pipe cleaner (dental type for cleaning between teeth) up in there. When the second hand carb body arrives I will also see how easy it is to extract the jet:

He didnt use any lube while turning, pulling on that jet. sccrreeek........... I'd be trying to find a collet to clamp on the outside of the tube rather than the easy out as a pulling tool. But now you know, it can be done!

I plan to make a collet type set of jaws to fit the vice grips. If I try them I will insert a 2.5mm drill bit down the tube to stop it collapsing under pressure.

The carb body arrived. I have cleaned it up in the ultra-sonic bath and checked all jets. Petrol flows through this body with less resistance, however tomorrow will be the big test...

The carb body arrived. I have cleaned it up in the ultra-sonic bath and checked all jets. Petrol flows through this body with less resistance, however tomorrow will be the big test...

New carb body now fitted. Surprise... Surprise... The pilot jet now works as it should...

I'm going to have a break for a day or two then make new gaskets for the carb bowls and finish off the carb tuning to see if I really needed that 0.5mm washer under the needle. I now believe the 0.5mm washer I added originally was only uping the fuel to compensate for the pilot circuit blockage.

Maybe have a go at pulling the jet from the old carb body next week...

I'm going to have a break for a day or two then make new gaskets for the carb bowls and finish off the carb tuning to see if I really needed that 0.5mm washer under the needle. I now believe the 0.5mm washer I added originally was only uping the fuel to compensate for the pilot circuit blockage.

Maybe have a go at pulling the jet from the old carb body next week...