I see from looking at the pics of your RLU that all it's wires were not connected. It looks like the blue/yellow wasn't hooked up, and that's an important one. Normally, headlight power from the safety relay is fed into the RLU on the blue/black wire. It runs out of the unit, up to the hi/lo switch, on that blue/yellow wire. So, I don't think your RLU was doing anything, not functioning at all, lol. The P.O. must have fed power into the blue/yellow wire that the one from the RLU is supposed to connect to. That would explain why your headlight functions without the need for a jumper wire after removing the RLU.

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

WELSH FLAT TRACK REVIVAL

- Thread starter Adamc

- Start date

It's a shame you haven't had much use out of the XS as yet. But this is shaping up to be a good Winter rebuild and you will have a bike you can really use as intended next year.

My only caution would be to take it easy on buying things. Which I'm sure you do already. It's all to easy to rush out and buy expensive parts and either change your mind or later realise they ain't mutually compatible. As soon as you step away from stock, you're kinda on your own as far as parts suitability goes. So it's sometimes easier to go step by step. But you got a whole long Welsh Winter to amuse your self so plenty time.

Yes you are wise Mr Raymond.

Alas the only standard kit on my bike are the frame and engine. Everything else is a Heinz variety mongrel. But I love it.

Last edited:

I see from looking at the pics of your RLU that all it's wires were not connected. It looks like the blue/yellow wasn't hooked up, and that's an important one. Normally, headlight power from the safety relay is fed into the RLU on the blue/black wire. It runs out of the unit, up to the hi/lo switch, on that blue/yellow wire. So, I don't think your RLU was doing anything, not functioning at all, lol. The P.O. must have fed power into the blue/yellow wire that the one from the RLU is supposed to connect to. That would explain why your headlight functions without the need for a jumper wire after removing the RLU.

Thanks 5T, that’s a good tip ref carb floats.

Good info on the wires too.

I intend to do a full rewire over the dark days of winter.

Wrap up warm, knuckle down and achieve one or two goals per day.

Then reward myself with a warming glass or two.

What a great thread gents. So many great links and info. Nicely done Adamc. I voted for you and look forward to February!

What a great thread gents. So many great links and info. Nicely done Adamc. I voted for you and look forward to February!

Thanks Van for the kind words and the vote!

Last edited:

COGNITO MOTO ARRIVAL

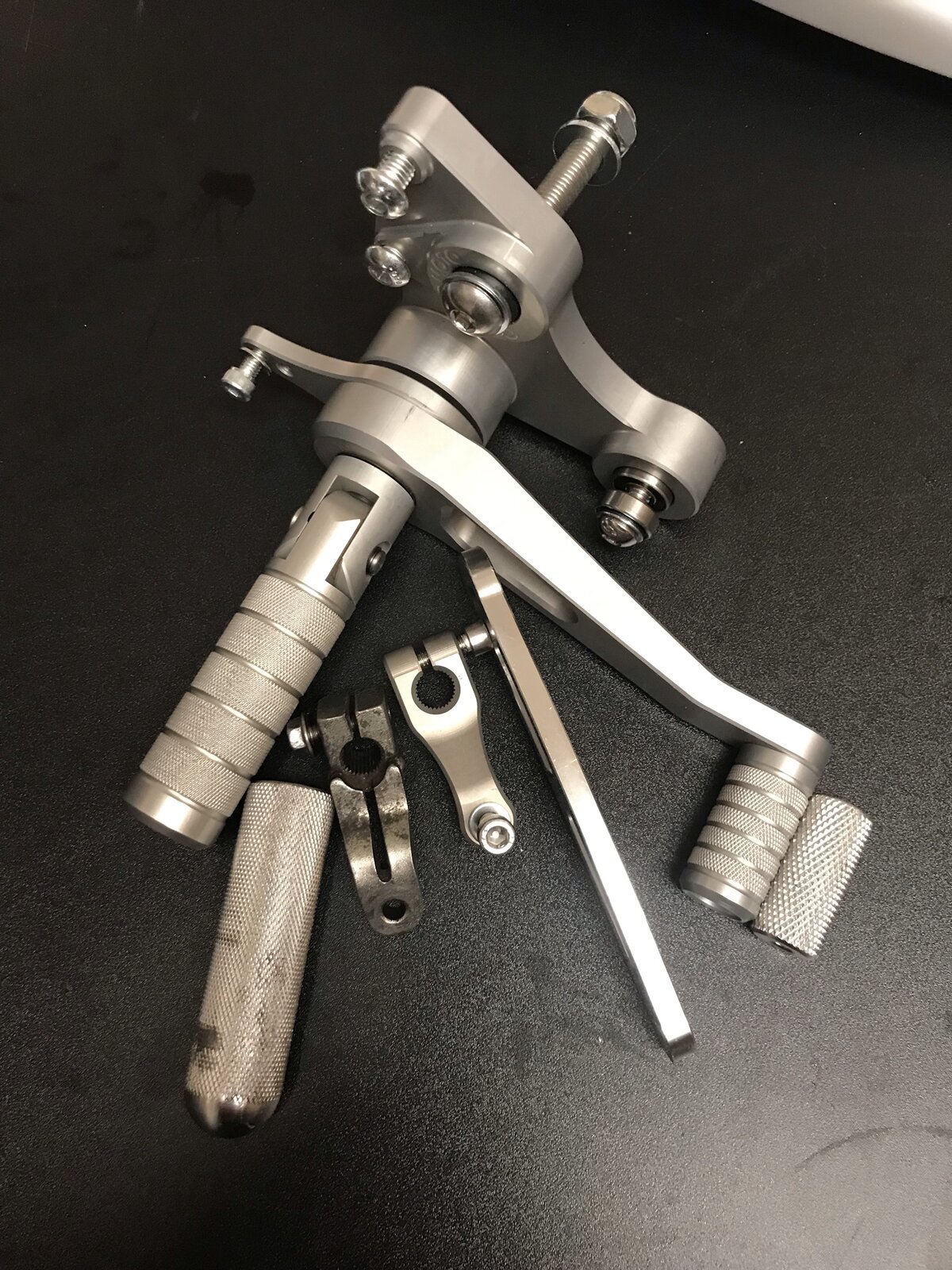

Christmas has finally come and gone and between it and the New Year my long awaited shipment arrived from Cognito Moto USA.

A box full of goodies for me to adapt The Welsh Flat Tracker to suit me better:

All the kit is XS650 specific. Here we have XS650 disc conversion hub to run standard size sprockets (Bike currently runs 40T rear due to off road Talon hub!) I may need to build a wheel around this if I cannot re-use the existing rim & spokes; a job for later. Wheel bearings for above. Nissin Rear brake cylinder. Frame mounting brackets, and rubber bushes for foot rests. Control levers. Rear disc brake mount. Splined gear selector. Rear brake master cylinder mount. Various bits & bobs.

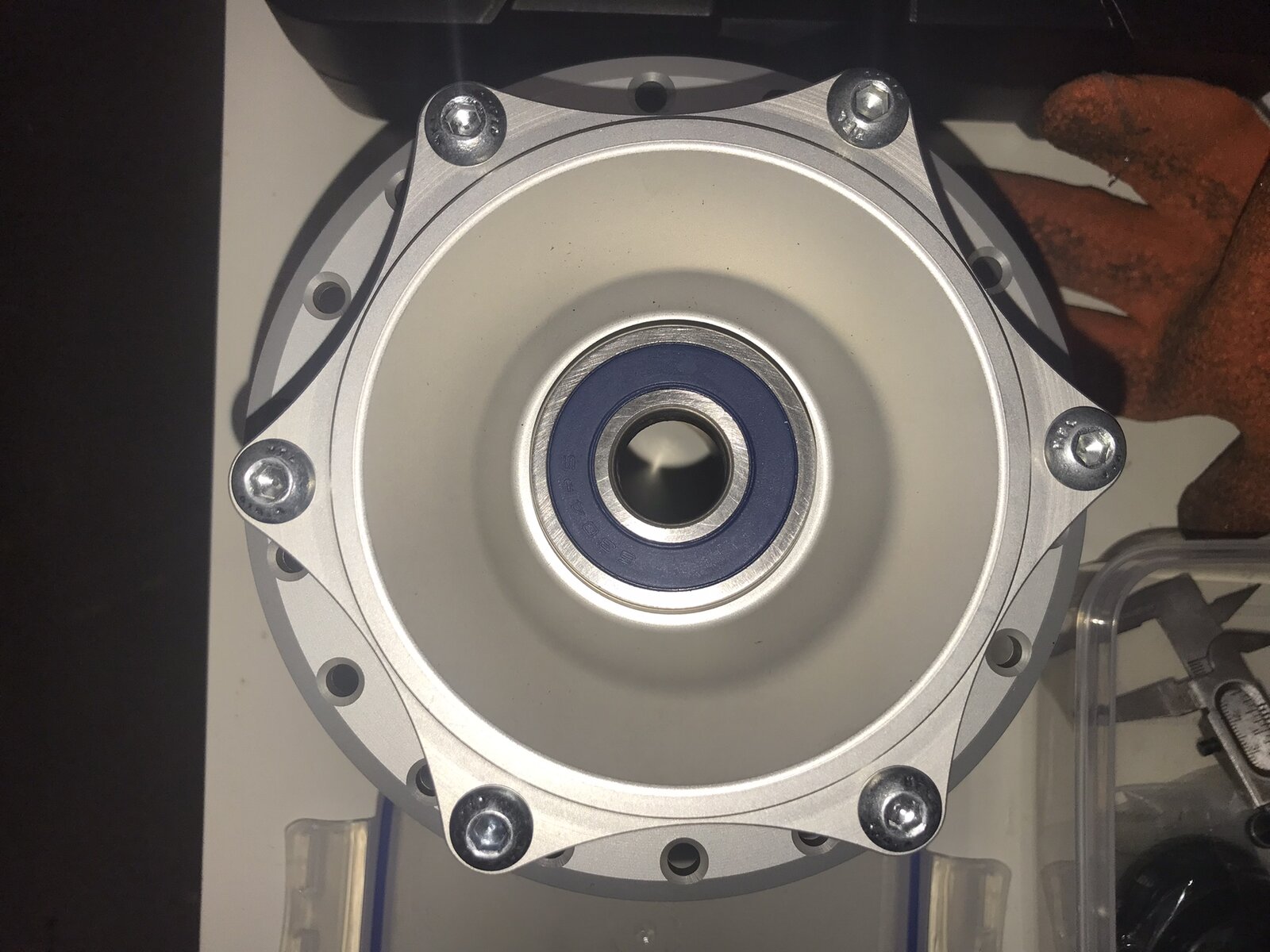

Quality of this Kit is excellent; both in engineering terms and machining:

First thing to look at would be the foot rests & levers. You may recall from this build thread I could not get a comfortable and safe working position for the Dan Moto rear sets fitted to the bike by the previous owner. Coupled with the fact that they fell apart on my first run after the bike refurbishment! They looked OK but the quality was Sh*tty. So time to remove the existing made from rear-sets; and simply bolt on the new kit....Easy!

rear-sets; and simply bolt on the new kit....Easy!

Fist image above shows Dan Moto RHS in situ. Second image shows LHS frame after removal of Dan Moto kit.

Well Roger me with a splintered baseball bat....Where are the mounting holes?

PO has welded up the mounting holes of the standard foot pegs; and welded shaped steel plates onto the frame to take the Dan Moto units.

So now I have nowhere to hang the new kit from.

After some thought I have two initial options:

I have two initial options:

1. DRASTIC MEASURE: Grind off the welded plates and re-drill the frame to original specification.

I would then refinish the damaged area of the frame as best as possible.

I have no datum references for the original foot peg holes; any help would be most welcome.

2. LESS DRASTIC: Re-drill the top mounting hole in the plate and tap a 10mm thread to take a mounting bolt to secure the Cognito top mount.

The Cognito bottom mount then sits below and to the left of the welded plate; so a spacer will be needed.

Like a number of members on this site I do not have the luxury of a fully kitted machine shop / garage (No welding skills or gear). This work will have to be done on a bike stand with engine is situ. Using more basic, but pro quality tools. As usual any thoughts or practical ideas are most welcome.

Ads.

Travis: What happened to my favourite 'Devil' Emoji?

Christmas has finally come and gone and between it and the New Year my long awaited shipment arrived from Cognito Moto USA.

A box full of goodies for me to adapt The Welsh Flat Tracker to suit me better:

All the kit is XS650 specific. Here we have XS650 disc conversion hub to run standard size sprockets (Bike currently runs 40T rear due to off road Talon hub!) I may need to build a wheel around this if I cannot re-use the existing rim & spokes; a job for later. Wheel bearings for above. Nissin Rear brake cylinder. Frame mounting brackets, and rubber bushes for foot rests. Control levers. Rear disc brake mount. Splined gear selector. Rear brake master cylinder mount. Various bits & bobs.

Quality of this Kit is excellent; both in engineering terms and machining:

First thing to look at would be the foot rests & levers. You may recall from this build thread I could not get a comfortable and safe working position for the Dan Moto rear sets fitted to the bike by the previous owner. Coupled with the fact that they fell apart on my first run after the bike refurbishment! They looked OK but the quality was Sh*tty. So time to remove the existing made from

rear-sets; and simply bolt on the new kit....Easy!

rear-sets; and simply bolt on the new kit....Easy!Fist image above shows Dan Moto RHS in situ. Second image shows LHS frame after removal of Dan Moto kit.

Well Roger me with a splintered baseball bat....Where are the mounting holes?

PO has welded up the mounting holes of the standard foot pegs; and welded shaped steel plates onto the frame to take the Dan Moto units.

So now I have nowhere to hang the new kit from.

After some thought

I have two initial options:

I have two initial options:1. DRASTIC MEASURE: Grind off the welded plates and re-drill the frame to original specification.

I would then refinish the damaged area of the frame as best as possible.

I have no datum references for the original foot peg holes; any help would be most welcome.

2. LESS DRASTIC: Re-drill the top mounting hole in the plate and tap a 10mm thread to take a mounting bolt to secure the Cognito top mount.

The Cognito bottom mount then sits below and to the left of the welded plate; so a spacer will be needed.

Like a number of members on this site I do not have the luxury of a fully kitted machine shop / garage (No welding skills or gear). This work will have to be done on a bike stand with engine is situ. Using more basic, but pro quality tools. As usual any thoughts or practical ideas are most welcome.

Ads.

Travis: What happened to my favourite 'Devil' Emoji?

My new favorite saying!Well Roger me with a splintered baseball bat....

It's a tough one to call. One tends to harbour unkind thoughts towards a PO who has modified the bike in a way that prevents putting it back. But the original mounting holes might still be there under the welded on plates. Might be possible to saw or grind them off?1. DRASTIC MEASURE: Grind off the welded plates and re-drill the frame to original specification.

I would then refinish the damaged area of the frame as best as possible.

I have no datum references for the original foot peg holes; any help would be most welcome.

Hi Raymond,It's a tough one to call. One tends to harbour unkind thoughts towards a PO who has modified the bike in a way that prevents putting it back. But the original mounting holes might still be there under the welded on plates. Might be possible to saw or grind them off?

I checked that from the inside of the frame; all welded up too, Bugger!

I'll give it a day or so and see if anyone has a better idea.

I'm not averse to grinding out the welds, hacking off the plates and re-drilling; but I will never get an exact colour frame match with paint to the existing powder coating.

Original pegs didn't mount into holes but rather onto shouldered studs welded to the frame .....

There were rubber grommets in each peg bracket hole. The bracket pushed onto the studs and was retained by some acorn nuts. Your new rear sets seem to mimic this mounting arrangement.

There were rubber grommets in each peg bracket hole. The bracket pushed onto the studs and was retained by some acorn nuts. Your new rear sets seem to mimic this mounting arrangement.

I don`t know how high on the frame your wanting to mount the new pegs but you could make a adaptor plate out of aluminum and bolt it onto the existing plate for the Dan Moto pegs using the existing bolt holes and add a third hole in a triangle pattern and countersink the bolts? Just a thought.

Thanks 5T. These are the clearest images I have seen. I am still considering any suggestions our motley crew can offer.Original pegs didn't mount into holes but rather onto shouldered studs welded to the frame .....

There were rubber grommets in each peg bracket hole. The bracket pushed onto the studs and was retained by some acorn nuts. Your new rear sets seem to mimic this mounting arrangement.

Thanks 5T. These are the clearest images I have seen. I am still considering any suggestions our motley crew can offer.Original pegs didn't mount into holes but rather onto shouldered studs welded to the frame .....

There were rubber grommets in each peg bracket hole. The bracket pushed onto the studs and was retained by some acorn nuts. Your new rear sets seem to mimic this mounting arrangement.

Halfmile. I did look at using the DM plate but it’s very perforated with holes for its own mounting. I may do as you say and make another plate to accept the new rear-sets. It will push the foot pegs out more, but it’s a good compromise. Thanks. AdsI don`t know how high on the frame your wanting to mount the new pegs but you could make a adaptor plate out of aluminum and bolt it onto the existing plate for the Dan Moto pegs using the existing bolt holes and add a third hole in a triangle pattern and countersink the bolts? Just a thought.

5T and 1/2mile have come up with a good initial soloution. It will allow me to combine the two and try a mount system that means I don’t need to butcher my frame. I will post what happens next soon.

Thanks to you both.

Ads

Thanks to you both.

Ads

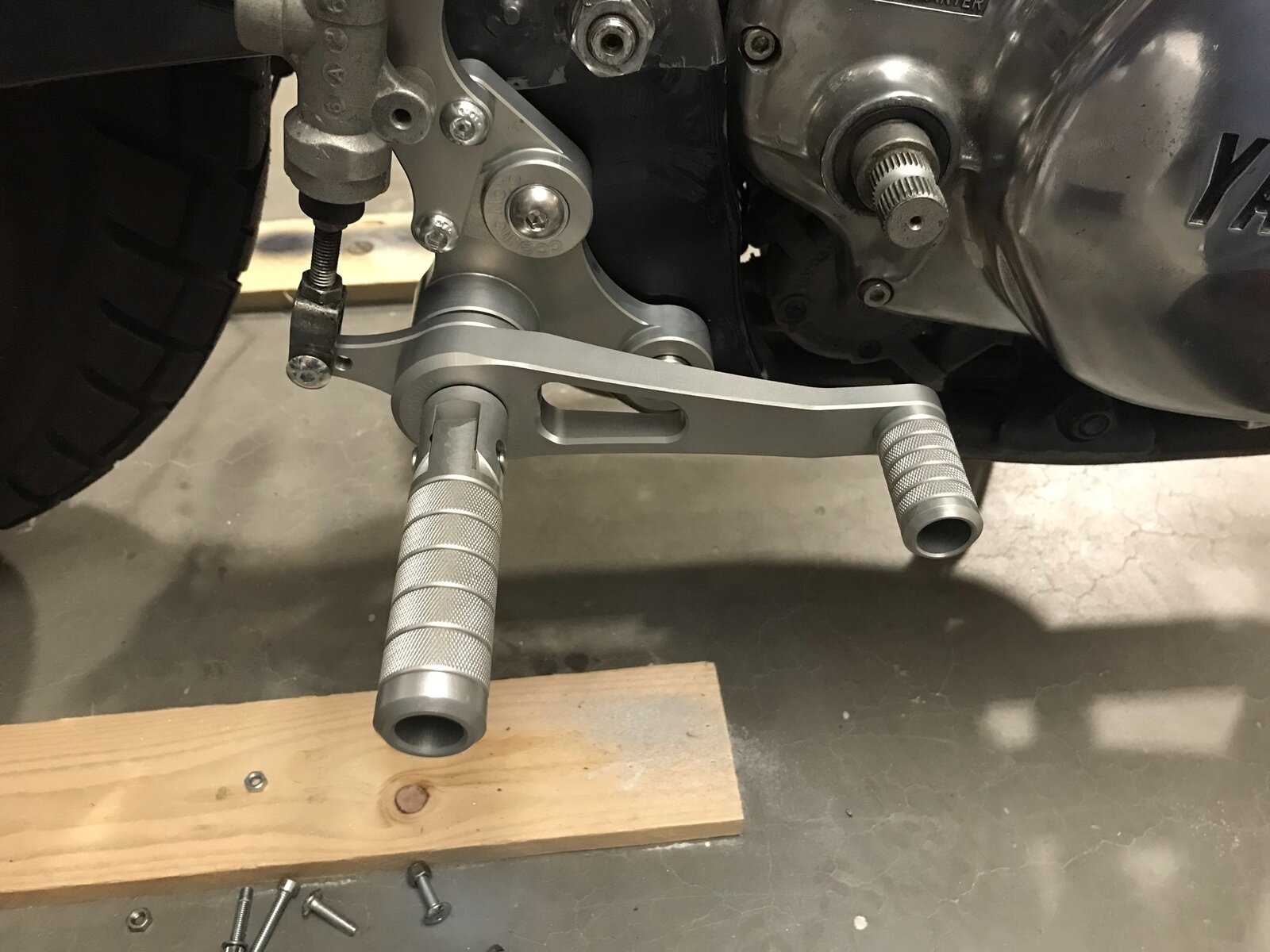

REAR-SETS OFF, REAR-SETS ON, REAR-SETS OFF, REAR-SETS ON...............Etc.....

The images below show the difference in quality and machining between the Dan-Moto units and the COGNITO.

COGNITO wins hands down both in material value and workmanship.

You can see the DM lever plus pegs in front of the COGNITO unit.

After considering the options that flooded in (Thanks 5T & 1/2 Mile); I bit the bullet.

Sod it, lets just grind off the welded plates of the Dan-Moto pegs and see whats what.

Same both sides so I now have an exposed steel frame with holes in!

A quick flash over with some primer to keep the rust at bay would suffice for now.

Time to look at mounting options.

The COGNITO sets are machined to fit the original XS650 threaded mounting stubs that are welded in place.

Mine are long gone so I need another solution. First I offered up the gear link side to find a suitable location.

I decided to fit the pegs a little lower than the Dan-Moto ones to offer more leg room as I'm well over 6' tall with long legs.

I drilled out a hole , top right, to accept a 10mm stainless steel button head hex bolt.

Same at the bottom for the lower fixing. The bottom holes I also tapped to accept the 10mm thread.

Top holes were bolted straight through with a security 'Nylock' nut on the back.

A test fit was next to confirm the peg positions, and lever actuation.

The frame was then tidied up with some bondo to remove nasty grinder marks.

Sanded down to an acceptable finish; primed & re-sanded then primed again.

The nearest paint match I could find in Halfords auto shop was Peugeot Graphite Grey metallic.

A couple of coats of the paint and topped off with some clear lacquer did an acceptable to me job.

This would do for now as I plan to completely refinish the whole frame next winter when funds permit.

In the test fit I ran the gear linkage under the lever and mount. This meant the link was a little too acutely angled.

It did work but I didn't like the look of it and felt it would stress the fittings over time.

Another strip down and I ran the link bar above the mount to the gearbox actuator.

This was far more satisfactory both visually and mechanically. Stainless button hex bolts used, with tread-lock to mount.

The link tube shown is just a temporary item to get the length right. I have a new one supplied with the rear-sets.

A test of the levers in the shop show them to be far more robust and solid feeling compared to the Dan-Moto units.

The Cognito sealed bearings are really smooth. The shift is 'snicekrty-snick' slick and very positive up and down the box.

Yes they were quite expensive to buy at $470.00 plus shipping; but for the material and quality of workmanship they are totally worth it to me. The feel of the machine has improved beyond my expectation. I now feel I can trust the machine to ride efficiently and safely. A feeling that the old DM units did not inspire.

Also I now longer need a triple joint ankle to work the things!

Next job is to build up a new rear disc wheel using the COGNITO XS650 wire wheel hub with disc conversion.

This will allow me to use a sensible 33 tooth rear sprocket, and ditch the 40 tooth brown pants wheelie maker currently installed.

brown pants wheelie maker currently installed.

The images below show the difference in quality and machining between the Dan-Moto units and the COGNITO.

COGNITO wins hands down both in material value and workmanship.

You can see the DM lever plus pegs in front of the COGNITO unit.

After considering the options that flooded in (Thanks 5T & 1/2 Mile); I bit the bullet.

Sod it, lets just grind off the welded plates of the Dan-Moto pegs and see whats what.

Same both sides so I now have an exposed steel frame with holes in!

A quick flash over with some primer to keep the rust at bay would suffice for now.

Time to look at mounting options.

The COGNITO sets are machined to fit the original XS650 threaded mounting stubs that are welded in place.

Mine are long gone so I need another solution. First I offered up the gear link side to find a suitable location.

I decided to fit the pegs a little lower than the Dan-Moto ones to offer more leg room as I'm well over 6' tall with long legs.

I drilled out a hole , top right, to accept a 10mm stainless steel button head hex bolt.

Same at the bottom for the lower fixing. The bottom holes I also tapped to accept the 10mm thread.

Top holes were bolted straight through with a security 'Nylock' nut on the back.

A test fit was next to confirm the peg positions, and lever actuation.

The frame was then tidied up with some bondo to remove nasty grinder marks.

Sanded down to an acceptable finish; primed & re-sanded then primed again.

The nearest paint match I could find in Halfords auto shop was Peugeot Graphite Grey metallic.

A couple of coats of the paint and topped off with some clear lacquer did an acceptable to me job.

This would do for now as I plan to completely refinish the whole frame next winter when funds permit.

In the test fit I ran the gear linkage under the lever and mount. This meant the link was a little too acutely angled.

It did work but I didn't like the look of it and felt it would stress the fittings over time.

Another strip down and I ran the link bar above the mount to the gearbox actuator.

This was far more satisfactory both visually and mechanically. Stainless button hex bolts used, with tread-lock to mount.

The link tube shown is just a temporary item to get the length right. I have a new one supplied with the rear-sets.

A test of the levers in the shop show them to be far more robust and solid feeling compared to the Dan-Moto units.

The Cognito sealed bearings are really smooth. The shift is 'snicekrty-snick' slick and very positive up and down the box.

Yes they were quite expensive to buy at $470.00 plus shipping; but for the material and quality of workmanship they are totally worth it to me. The feel of the machine has improved beyond my expectation. I now feel I can trust the machine to ride efficiently and safely. A feeling that the old DM units did not inspire.

Also I now longer need a triple joint ankle to work the things!

Next job is to build up a new rear disc wheel using the COGNITO XS650 wire wheel hub with disc conversion.

This will allow me to use a sensible 33 tooth rear sprocket, and ditch the 40 tooth

brown pants wheelie maker currently installed.

brown pants wheelie maker currently installed.

Good work!

You took the chance, just jump in and see what you would find, and you dealt with what you found, practical solutions, well executed. Dare I say that this informative and supportive forum maybe helped by giving you the confidence to venture a little further into the unknown? I know it has for me.

You took the chance, just jump in and see what you would find, and you dealt with what you found, practical solutions, well executed. Dare I say that this informative and supportive forum maybe helped by giving you the confidence to venture a little further into the unknown? I know it has for me.

Couldn’t agree more Raymond. I did jump in with this a bit. The gang on this forum do give confidence to tackle anything; if it goes Pete-Tong they can offer advice to put it right. At the end it’s just metal parts which can be put back. I need to learn to welding; it seems welding can right wrongs.Good work!

You took the chance, just jump in and see what you would find, and you dealt with what you found, practical solutions, well executed. Dare I say that this informative and supportive forum maybe helped by giving you the confidence to venture a little further into the unknown? I know it has for me.

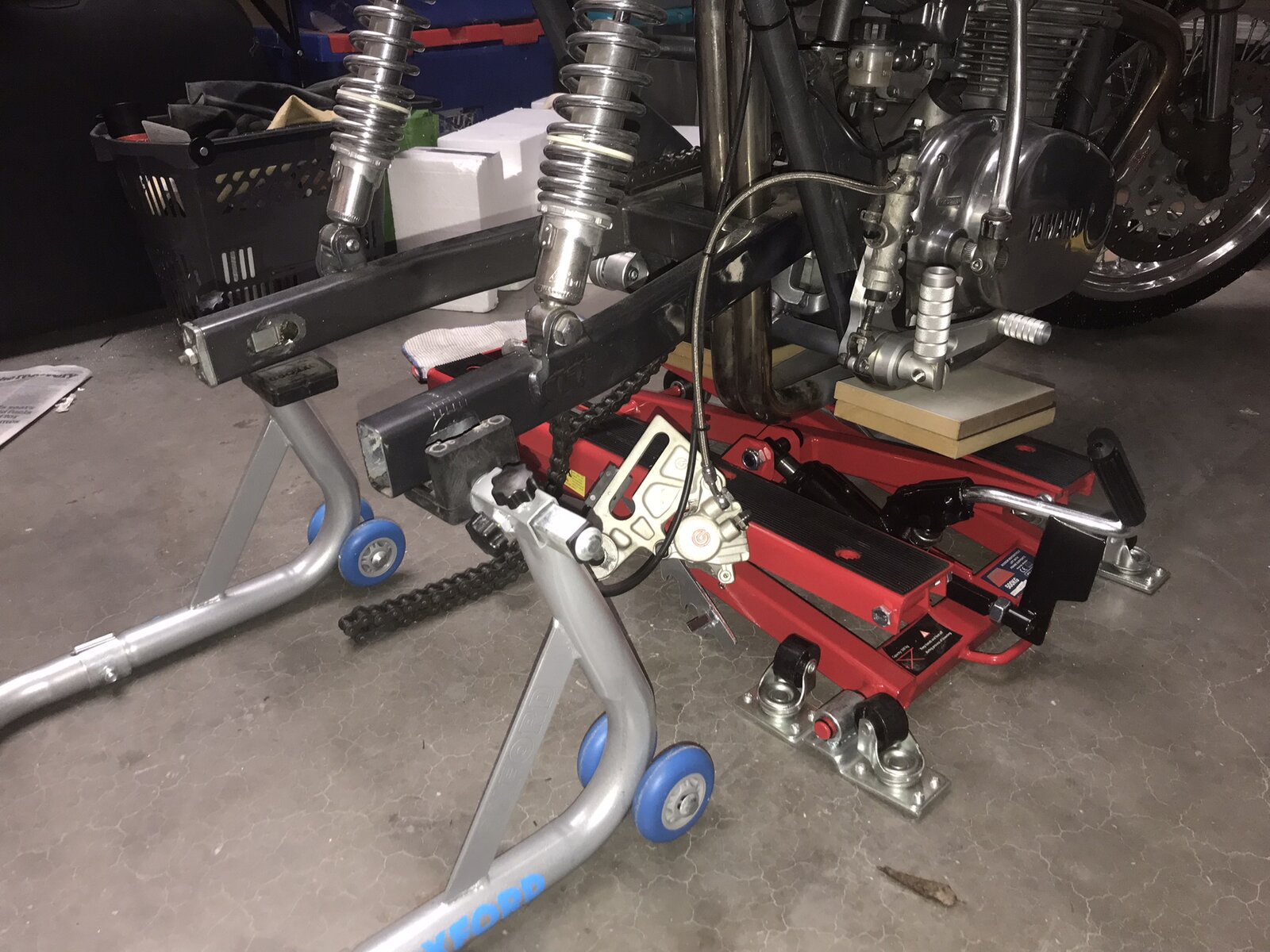

AN UPLIFTING EXPERIENCE

If you have followed this thread above you will recall I have a low gearing issue with the bike severely limiting top speed.

My bike has no center stand, and my rear paddock stand fouls the disc caliper. I need a solution to remove the back wheel.

For my wife's birthday I decided to think out of the box and bought her a bike lift....Genius!

I needed a lift that had some adjustment to clear the low slung exhausts and side stand mount.

Sealey seemed to have just the thing:

I was impressed with the build quality and lovely red colour to match my bike!

The Missus was not so enamored; so an expensive night with dinner at a hotel recovered some brownie points.

In use the lift did not quite work so well. The adjustable supports would not fit under the frame, Bugger.

I was forced to use some packing blocks on one side of the lift to achieve a suitable height to remove the spindle and wheel.

Once the wheel was out I used the paddock stand as a belt and braces approach to stop the bike toppling over.

Its far more secure than the image looks, so all good so far.

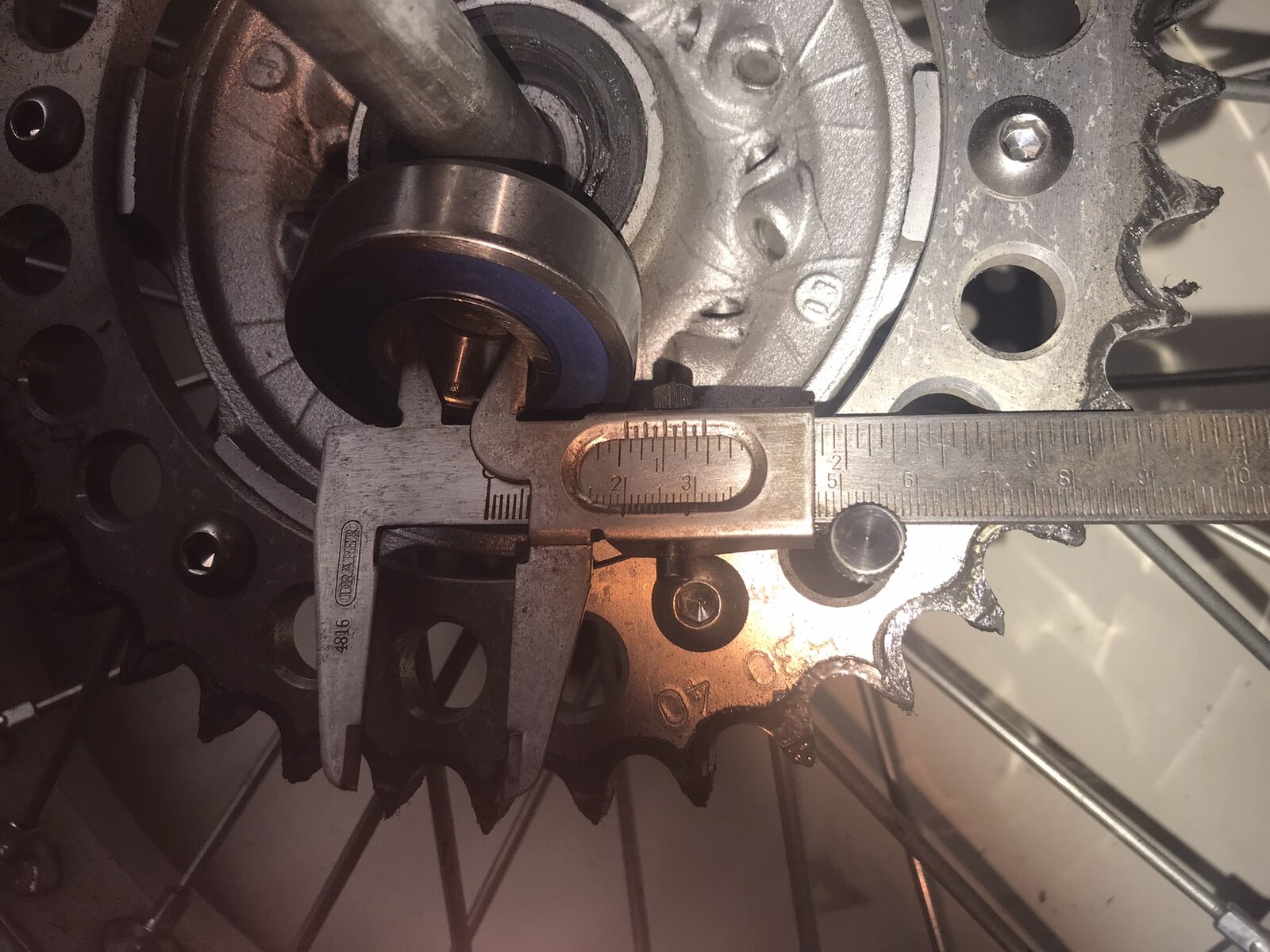

Next up was to check the fit of the existing wheel spindle with the new COGNITO MOTO disc hub.

I knew there would be a difference but was unsure which way it would go.

The COGNITO hub is a disc conversion type for wire wheel use.

HUSQVARNA HUB / COGNITO MOTO HUB

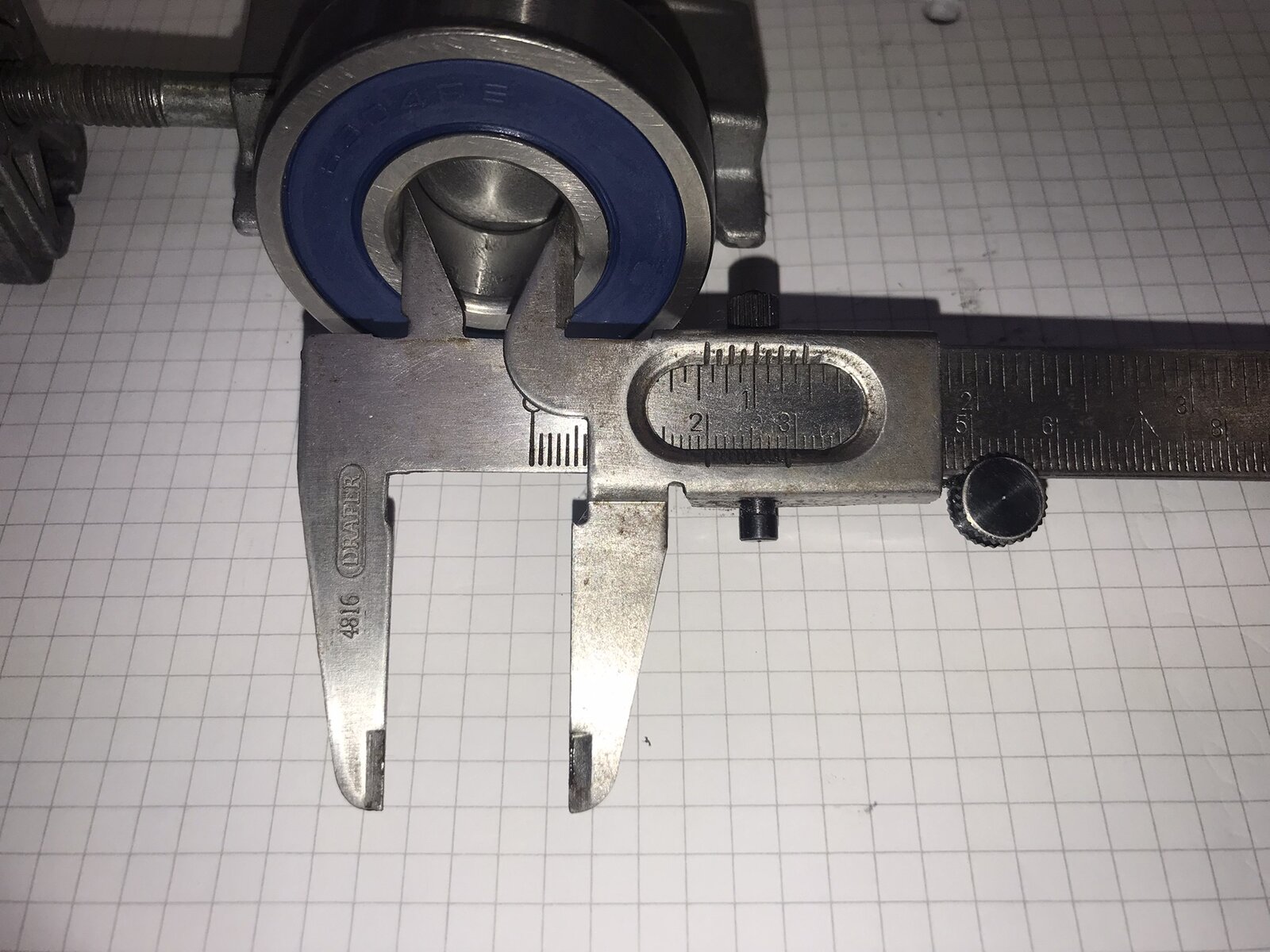

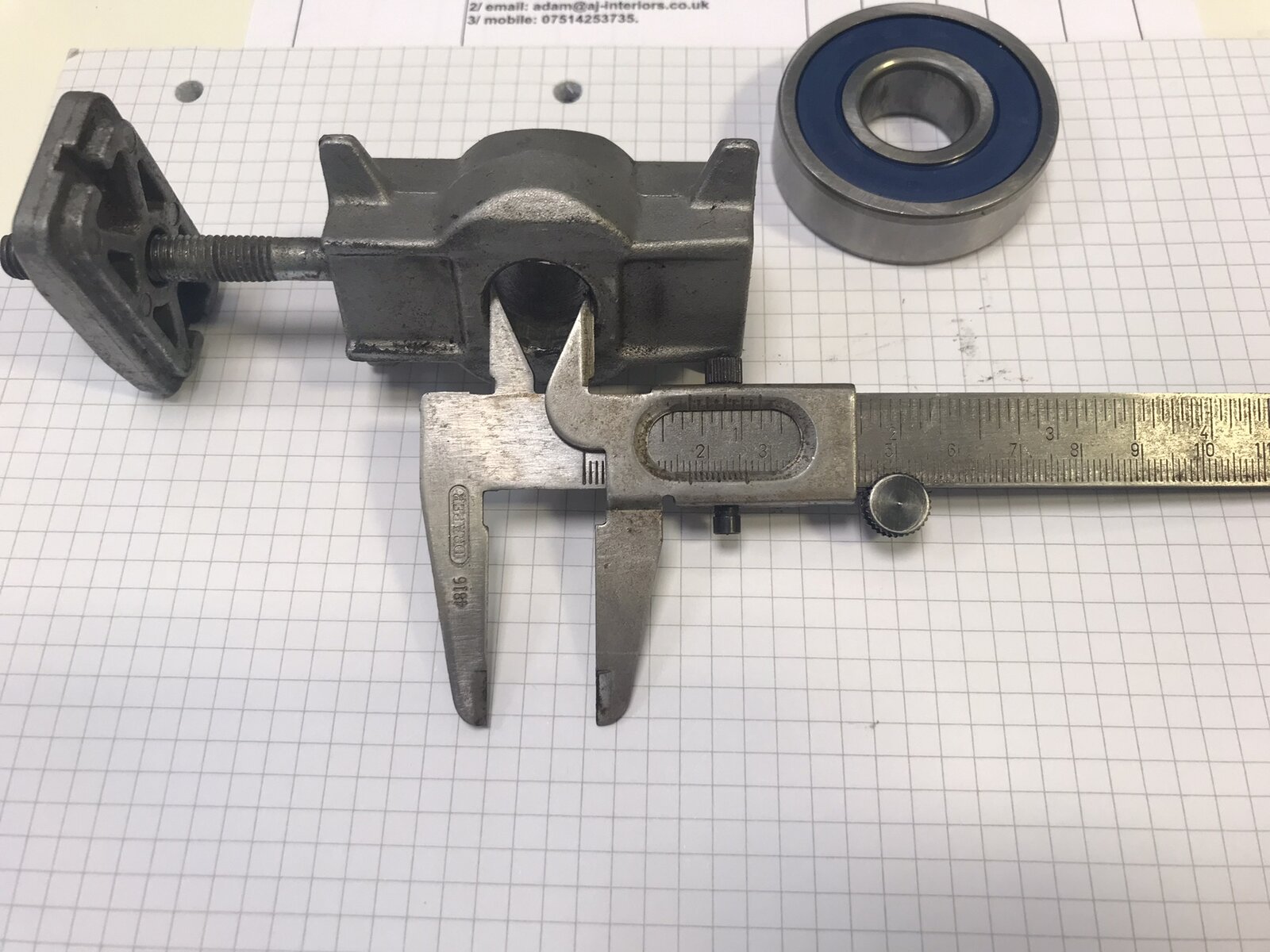

HUSQVARNA HUB 17mm DIAMETER / COGNITO BEARING IS 20mm DIAMETER

So I have a difference of 3mm larger spindle needed. The COGNITO unit is machined to accept standard XS650 parts.

My machine is all custom built using a swing arm from a more modern Yamaha; and hubs and axles from a Husqvarna.

I had planned to use the existing rim built up on the new hub; but may have to get a total new wheel built to the hub.

I now have a quandary as to whether I can machine the chain adjusters and swing arm slots to accept the larger standard XS650 spindle.

This will require the removal of the swing arm, and me finding a machine shop to do it (Unless you guys have a Black & Decker / Hammer option?).

Or can I 'sleeve' the Husky spindle to fit the new bearings? Any suggestions from the troops here would be welcome.

I look forward to your advice.

Ads.

If you have followed this thread above you will recall I have a low gearing issue with the bike severely limiting top speed.

My bike has no center stand, and my rear paddock stand fouls the disc caliper. I need a solution to remove the back wheel.

For my wife's birthday I decided to think out of the box and bought her a bike lift....Genius!

I needed a lift that had some adjustment to clear the low slung exhausts and side stand mount.

Sealey seemed to have just the thing:

I was impressed with the build quality and lovely red colour to match my bike!

The Missus was not so enamored; so an expensive night with dinner at a hotel recovered some brownie points.

In use the lift did not quite work so well. The adjustable supports would not fit under the frame, Bugger.

I was forced to use some packing blocks on one side of the lift to achieve a suitable height to remove the spindle and wheel.

Once the wheel was out I used the paddock stand as a belt and braces approach to stop the bike toppling over.

Its far more secure than the image looks, so all good so far.

Next up was to check the fit of the existing wheel spindle with the new COGNITO MOTO disc hub.

I knew there would be a difference but was unsure which way it would go.

The COGNITO hub is a disc conversion type for wire wheel use.

HUSQVARNA HUB / COGNITO MOTO HUB

HUSQVARNA HUB 17mm DIAMETER / COGNITO BEARING IS 20mm DIAMETER

So I have a difference of 3mm larger spindle needed. The COGNITO unit is machined to accept standard XS650 parts.

My machine is all custom built using a swing arm from a more modern Yamaha; and hubs and axles from a Husqvarna.

I had planned to use the existing rim built up on the new hub; but may have to get a total new wheel built to the hub.

I now have a quandary as to whether I can machine the chain adjusters and swing arm slots to accept the larger standard XS650 spindle.

This will require the removal of the swing arm, and me finding a machine shop to do it (Unless you guys have a Black & Decker / Hammer option?).

Or can I 'sleeve' the Husky spindle to fit the new bearings? Any suggestions from the troops here would be welcome.

I look forward to your advice.

Ads.

Looks like your using a Radian swingarm with the 17mm axle. If the OD of the Cognito bearing is the same as the XS650 bearing I believe the 20mm ID is all that is available. I`ve done it both ways, sleeve the rear to 17mm and/or enlarge the chain adjusters and slot in the swingarm to 20mm. Both are a pain in the ass unless you have a mill and lathe. Sleeve`s let you use the stock Radian axle. I think the popular 20mm axle used for the Radian swingarm is a CB750 Honda axle. I made the sleeve`s and spacers in one piece. Too bad no one makes the conversion bearing.

Thanks Halfmile, I had a feeling it would be more work than I'm capable of.Looks like your using a Radian swingarm with the 17mm axle. If the OD of the Cognito bearing is the same as the XS650 bearing I believe the 20mm ID is all that is available. I`ve done it both ways, sleeve the rear to 17mm and/or enlarge the chain adjusters and slot in the swingarm to 20mm. Both are a pain in the ass unless you have a mill and lathe. Sleeve`s let you use the stock Radian axle. I think the popular 20mm axle used for the Radian swingarm is a CB750 Honda axle. I made the sleeve`s and spacers in one piece. Too bad no one makes the conversion bearing.

View attachment 207977View attachment 207978

Having done both, which did you find the easier option?

Similar threads

- Replies

- 5

- Views

- 259