Yes.should the holes not be arranged to cover the full width of the swept area?

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What have you done to your XS today?

- Thread starter I am Carbon

- Start date

-

- Tags

- maintenance

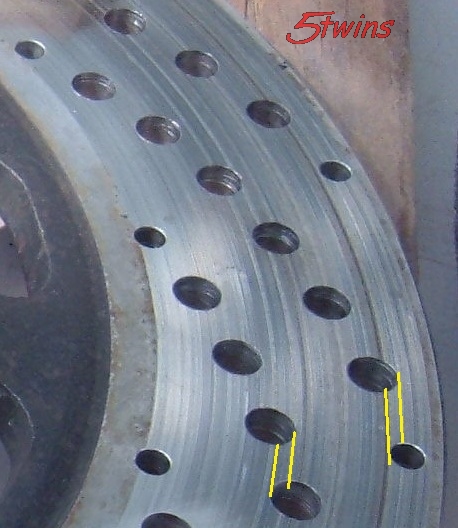

Yes, that's an important aspect of the hole pattern. You want the holes to overlap one another, the edge of one lapping into the next hole in the pattern. The score lines from the pads on this disc I drilled recently nicely illustrate this hole overlap .....

@lakeview scored a very nice looking bike.

My thought exactly, didn't want to mention it.

Yes.

In the picture you can see however that the disc does have pronounced different appearance where the holes do not clean the brake pad. Not a critical deficiency IMHO but something to watch as the miles roll up.Yes, that's an important aspect of the hole pattern. You want the holes to overlap one another, the edge of one lapping into the next hole in the pattern. The score lines from the pads on this disc I drilled recently nicely illustrate this hole overlap .....

View attachment 214962

View attachment 214963

Now you'll have me worried while I'm draggin' a knee on the Dragon!

I had boat yard duties today and after a long day dealing with unprepared owners (they have been doing this shit for decades) I got to enjoy some decent riding weather to run some errands. With good hot oil when I got home, I dropped the drain plugs in preparation to inspect the sump strainer. I have not done this before. I now have ~700 miles on the new to me XS650/750 and this is the 3rd or 4th time I have drained the oil. This time I will do the @gggGary clutch upgrade and finally look at the strainer. I have to remove the left exhaust to drop the sump plate. What do I need to look for beyond obvious damage and excess particles? Then, do I clean with soap and water? Last time I changed oil was to install heavier clutch springs which were a short-lived fix for a clutch either at the end of useful life or overwhelmed by a 750 BBK. NEITHER matter in this XS quest of XS nirvana .

'Spose soap and water would work fine, as always I'm a fan of mineral spirits and compressed air.

Hopefully your PO didn't use sealer on BOTH sides of the gasket.

One of my least favorite XS jobs is scraping glued gasket off the motor's belly.

Sharpened hacksaw blade a favorite tool for this, Note how I round scraper corners so no aluminum gets gouged.

Two on left made from windshield wiper stainless strip.

Hopefully your PO didn't use sealer on BOTH sides of the gasket.

One of my least favorite XS jobs is scraping glued gasket off the motor's belly.

Sharpened hacksaw blade a favorite tool for this, Note how I round scraper corners so no aluminum gets gouged.

Two on left made from windshield wiper stainless strip.

When you open up the sump plate more than likely you'll see the sump screen have an area where the screen is torn so that will have to be fixedI had boat yard duties today and after a long day dealing with unprepared owners (they have been doing this shit for decades) I got to enjoy some decent riding weather to run some errands. With good hot oil when I got home, I dropped the drain plugs in preparation to inspect the sump strainer. I have not done this before. I now have ~700 miles on the new to me XS650/750 and this is the 3rd or 4th time I have drained the oil. This time I will do the @gggGary clutch upgrade and finally look at the strainer. I have to remove the left exhaust to drop the sump plate. What do I need to look for beyond obvious damage and excess particles? Then, do I clean with soap and water? Last time I changed oil was to install heavier clutch springs which were a short-lived fix for a clutch either at the end of useful life or overwhelmed by a 750 BBK. NEITHER matter in this XS quest of XS nirvana .

I believe you'll find it's just fine or the damage is obvious. The first time I replaced mine it was because a long time Yamaha dealer told me it was the Achilles heel of the bike. So, I replaced a perfectly good strainer. I've never torn one. Opening up other engines they've been damaged 100% and the damage is always obvious.When you open up the sump plate more than likely you'll see the sump screen have an area where the screen is torn so that will have to be fixed

I've also used some gasket remover jell it doesn't just make the gasket just peal off but it did help a little to release the stubborn areas'Spose soap and water would work fine, as always I'm a fan of mineral spirits and compressed air.

Hopefully your PO didn't use sealer on BOTH sides of the gasket.

One of my least favorite XS jobs is scraping glued gasket off the motor's belly.

Sharpened hacksaw blade a favorite tool for this, Note how I round scraper corners so no aluminum gets gouged.

Two on left made from windshield wiper stainless strip.

View attachment 215034

For stuck-on gasket around the bottom of the crankcases, I find a little nitromors paint remover applied with a fine paint brush loosens it up - leave it for a few minutes, can then push it off with a plastic scraper or whatever. Put the new gasket on with a smear of grease on the engine side and it should release easy next time.

I've tried that.I like to tape a $20 bill under the seat, it has come in handy a couple of times.

tim

Man she slapped me HARD.

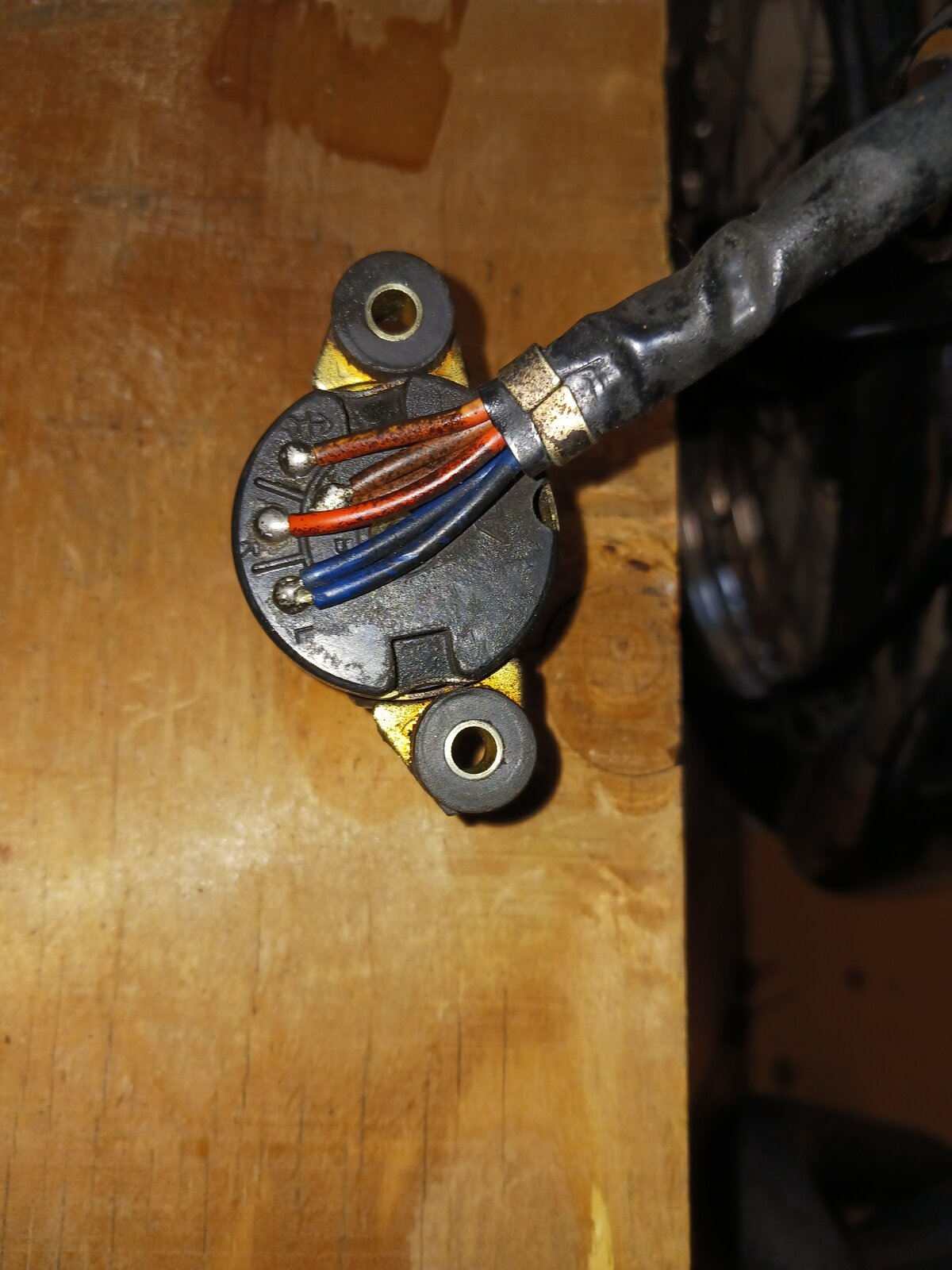

First things first. At the Ozark rally, I had an intermittent tail light. Resolving that with John, Gary and maybe others (thanks to all) it was pointed out that I probably had a dirty ignition switch because of an excessive voltage drop. 1 - 1 1/2volts. So with rain coming through I disassembled. My ignition harness goes into the headlight bucket. Stock probably does to but I have a small 5 inch H/L and a dainty size bucket and the hole and grommet the wiring goes through seems smaller than some of the double barrel connectors, like a good doctor, "first, do no harm" I decided not to try to fish out the harness but ser up a surface next to the bike. I unmounted the switch and it is not like those in the ignition switch thread.

@gggGary sent me this.

https://www.xs650.com/threads/ignition-switch-repair.60639/

https://www.xs650.com/threads/ignition-switch-overhaul.46712/

Good info there.

My switch looks like this. No small parts to lose but the disassembly was bending pinched section on the bottom to an "unpinched" state so the contact section could be removed. Cleaned contacts with 400 grit, reassembled and now voltage drop is 0.4 to 0.5 volt.

@gggGary sent me this.

https://www.xs650.com/threads/ignition-switch-repair.60639/

https://www.xs650.com/threads/ignition-switch-overhaul.46712/

Good info there.

My switch looks like this. No small parts to lose but the disassembly was bending pinched section on the bottom to an "unpinched" state so the contact section could be removed. Cleaned contacts with 400 grit, reassembled and now voltage drop is 0.4 to 0.5 volt.

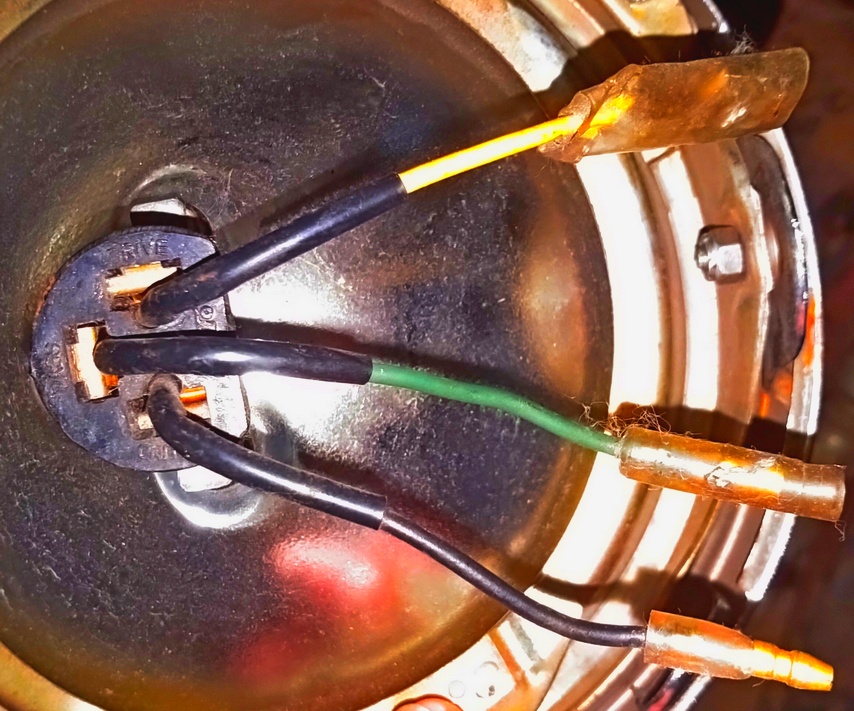

You'll be fine, but for the most part I just use metal polish on copper contacts, all you need to get them clean and shiny while not removing metal that doesn't need to disappear. You can go up to 600 grit if there are deep scratches then polish. Don't forget to check how the headlight bulb wires are connected.

We thought your high beam and ground wires were reversed.

Factory wires;

-- High beam - yellow

| Low beam - green

__ Ground - black

Edit 5-25-2022 3:30PM CST; cuz random web wiring diagram not correct, grr all better now, LOL

We thought your high beam and ground wires were reversed.

Factory wires;

-- High beam - yellow

| Low beam - green

__ Ground - black

Edit 5-25-2022 3:30PM CST; cuz random web wiring diagram not correct, grr all better now, LOL

Last edited:

Thanks gggGary, reminding me of a "to do" item I had let slip. I get to figure out what wire color the PO used.

My Gnd goes through an indicator (hi beam?) back to yellow so it is all wrong. I will jumper some things in, maybe bypass that indicator bulb which is dead anyway and get a proper low/high set up. I have the tools and supplies.You'll be fine, but for the most part I just use metal polish on copper contacts, all you need to get them clean and shiny while not removing metal that doesn't need to disappear. You can go up to 600 grit if there are deep scratches then polish. Don't forget to check how the headlight bulb wires are connected.

We thought your high beam and ground wires were reversed.

Factory wires;

-- High beam - yellow

| Low beam - green

__ Ground - black

View attachment 215076

Edit 5-25-2022 3:30PM CST; cuz random web wiring diagram not correct, grr all better now, LOL

Next up, remove left header pipe to drop the sump.

My gnd is riveted to the headlight shell near the indicator so all is correct and the bulb may be suspect. Auto bulb 55w/60w likely.My Gnd goes through an indicator (hi beam?) back to yellow so it is all wrong. I will jumper some things in, maybe bypass that indicator bulb which is dead anyway and get a proper low/high set up. I have the tools and supplies.

You headed down there? Our car club was there a month ago. I didn’t go this year but would like to go next year with the bike(s).Now you'll have me worried while I'm draggin' a knee on the Dragon!

I may have too finish this up, roll it into the living room and get a user friendly XSMy gnd is riveted to the headlight shell near the indicator so all is correct and the bulb may be suspect. Auto bulb 55w/60w likely.

I will use that less abusive approach in the future. Thank you.You'll be fine, but for the most part I just use metal polish on copper contacts, all you need to get them clean and shiny while not removing metal that doesn't need to disappear.

Factory wires;

-- High beam - yellow

| Low beam - green

__ Ground - black

View attachment 215076

Edit 5-25-2022 3:30PM CST; cuz random web wiring diagram not correct, grr all better now, LOL

Similar threads

- Replies

- 32

- Views

- 1K