Bear1

XS650 Member

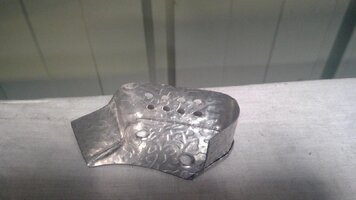

Not particularly important but I am going through a 1979 engine and will be replacing the Oil Strainer with a new strainer from MikesXS with the improved screen support. My question is should I just toss the old one or save it? Back in the day I repaired them, but I don't plan to do that. I can clean it up if anyone is interested in repairing it for themselves.