XS 850 Rehash.

My holiday plans were disrupted by weather, so I have been in the shed working. I thought some of you might be interested in a project that has been ongoing for a while. So with the unplanned extra time I have decided to launch in to print.

Some time ago I got hold of an XS850. It was basically complete but in pretty bad condition.

With the bike came another 850 Engine in pieces and a XS 750 also in pieces , but most importantly a set of Japanese market GX750 wire wheels.

The wheels were rusted beyond redemption, and I made the costly mistake of having them professionally rebuilt. They look great but the cost is still giving me heart burn.

This has been a back burner project and over time my plans have changed from a full blown café racer with clip on’s to a more sedate 80,s period style (sort of but not strictly period) sport bike. In my mind I see a 80s race bike replica, although I don’t remember anyone successfully campaigning one of these here.

Realistically its going to be a sheep in wolfs clothing. So, with that slightly confused sense of direction here are some of the main things I have been doing over the last few years.

I bought a single race seat that is for an XS and a Honda CB900f tank. I also have sourced a GPZ 750 rectangular headlight and a GPZ style bikini fairing.

The seat needs some work as it does not look quite right, I am going to try making the rear a bit wider and less tapered.

CB tank and XS 650 race seat .

Going away from the round headlight was an easy decision as I felt the original one was huge and would not look out of place on the front of an old Bentley tourer.

I needed to make new fork clamps and ears. The ears could do with some go faster holes in them, but I am holding off in case I need to mount something.

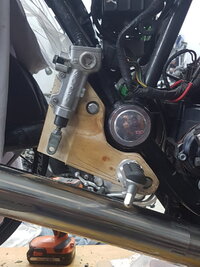

Mounting the bikini fairing was a learning experience as in the past I have fitted them to a bike that had a headlight mounted so mounted the headlight first. Then after fitting the fairing it would not adjust to look right and match up to the headlight.

So starting again mounted the fairing got it looking mostly right then worked out where the light needed to be.

I have cut off the XS rear subframe just aft of the shock mounts and made up a new sub frame with a bracket to mount a GPZ 250 tail light.

The tank was a bit tricky to fit and required a lot of hammer work to get it on. I have also changed the filler to an aircraft style one, relocated the fuel tap and added an external breather. The front tank mounts on the frame needed altering. The tank internally was a bit rusty and needed a long electrolysis session to clean it up, it is sealed up with ½ a litre of diesel in it for now. The fuel tap has been converted from vacuum to manual operation. The filler conversion is not the prettiest but with some body filler will come up well.

Sort of a ship in a bottle anode. The outer arms of the anode are held by a bolt and can be opened out once through the filler hole, plastic tubing on the ends helps ensure it does not short out.

I have upgraded the brake callipers to R1 blue spots and replaced the front discs with floating 320mm ones , the rear disc is a standard XS one cleaned up and drilled. It needed to be spaced off to suit the new calliper. I also needed to make another torque arm to suit the R1 calliper hanger that only needed the axel hole enlarged.

It now has a fibreglass front guard (a copy of a GPZ one) made by a mate as a thank you for some lathe work I did for him. Pleased with the un-sprung weight reduction, I then added weight in the form of a fork brace. The brace still needs some work tiding it up after some over enthusiastic drilling.

And some photos of making it. I have ordered some new dust seals.

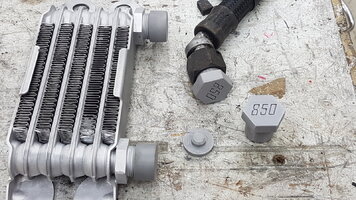

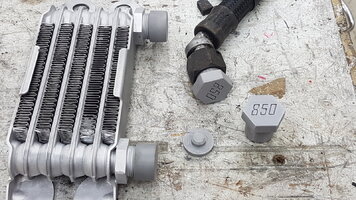

The oil cooler was removed, and bead blasted and I re zinced the front oil tubes I needed to block off the oil ways on the cooler and found the 3D printer very handy for making some disposable bungs, I also had a play in adding text to a print.

My holiday plans were disrupted by weather, so I have been in the shed working. I thought some of you might be interested in a project that has been ongoing for a while. So with the unplanned extra time I have decided to launch in to print.

Some time ago I got hold of an XS850. It was basically complete but in pretty bad condition.

With the bike came another 850 Engine in pieces and a XS 750 also in pieces , but most importantly a set of Japanese market GX750 wire wheels.

The wheels were rusted beyond redemption, and I made the costly mistake of having them professionally rebuilt. They look great but the cost is still giving me heart burn.

This has been a back burner project and over time my plans have changed from a full blown café racer with clip on’s to a more sedate 80,s period style (sort of but not strictly period) sport bike. In my mind I see a 80s race bike replica, although I don’t remember anyone successfully campaigning one of these here.

Realistically its going to be a sheep in wolfs clothing. So, with that slightly confused sense of direction here are some of the main things I have been doing over the last few years.

I bought a single race seat that is for an XS and a Honda CB900f tank. I also have sourced a GPZ 750 rectangular headlight and a GPZ style bikini fairing.

The seat needs some work as it does not look quite right, I am going to try making the rear a bit wider and less tapered.

CB tank and XS 650 race seat .

Going away from the round headlight was an easy decision as I felt the original one was huge and would not look out of place on the front of an old Bentley tourer.

I needed to make new fork clamps and ears. The ears could do with some go faster holes in them, but I am holding off in case I need to mount something.

Mounting the bikini fairing was a learning experience as in the past I have fitted them to a bike that had a headlight mounted so mounted the headlight first. Then after fitting the fairing it would not adjust to look right and match up to the headlight.

So starting again mounted the fairing got it looking mostly right then worked out where the light needed to be.

I have cut off the XS rear subframe just aft of the shock mounts and made up a new sub frame with a bracket to mount a GPZ 250 tail light.

The tank was a bit tricky to fit and required a lot of hammer work to get it on. I have also changed the filler to an aircraft style one, relocated the fuel tap and added an external breather. The front tank mounts on the frame needed altering. The tank internally was a bit rusty and needed a long electrolysis session to clean it up, it is sealed up with ½ a litre of diesel in it for now. The fuel tap has been converted from vacuum to manual operation. The filler conversion is not the prettiest but with some body filler will come up well.

Sort of a ship in a bottle anode. The outer arms of the anode are held by a bolt and can be opened out once through the filler hole, plastic tubing on the ends helps ensure it does not short out.

I have upgraded the brake callipers to R1 blue spots and replaced the front discs with floating 320mm ones , the rear disc is a standard XS one cleaned up and drilled. It needed to be spaced off to suit the new calliper. I also needed to make another torque arm to suit the R1 calliper hanger that only needed the axel hole enlarged.

It now has a fibreglass front guard (a copy of a GPZ one) made by a mate as a thank you for some lathe work I did for him. Pleased with the un-sprung weight reduction, I then added weight in the form of a fork brace. The brace still needs some work tiding it up after some over enthusiastic drilling.

And some photos of making it. I have ordered some new dust seals.

The oil cooler was removed, and bead blasted and I re zinced the front oil tubes I needed to block off the oil ways on the cooler and found the 3D printer very handy for making some disposable bungs, I also had a play in adding text to a print.