XS650 Clutch Worm Actuator Rotation Guage (degree wheel)

This is a companion piece to the XS650 clutch actuator experiments:

Clutch worm actuator experiments and tidbits

Clutch worm mod testing

Clutch pushrod experiments and tidbits

Clutch cable experiments and tidbits

I've been using a homemade dialgauge adapter to measure worm actuator plunge depths:

Clutch worm depth dialgauge-post90

Clutch worm depth dialgauge-post91

Clutch worm depth dialgauge-post92

But making that dialgauge adapter is a bit involved, so here's a little project that uses simple household appliances and kitchen utensils. Should keep you occupied while snowed-in.

The XS650 clutch worm actuator rotates to create the lateral movement that pushes the clutch pushrod, about 0.0035" per degree of rotation (about 0.003" for the different pitch MikesXS worm mechanism). The amount of rotation can be measured with a homemade degree wheel to estimate how much pushrod travel might be achieved (minus cable and mechanism slack). The amount of rotation is partially influenced by the length of the worm actuator arm, which can be anywhere from 1.2" to 1.8", depending on worm model. The amount of rotation is also influenced by the clutch cable, which, depending on brand and condition, can stretch at different rates.

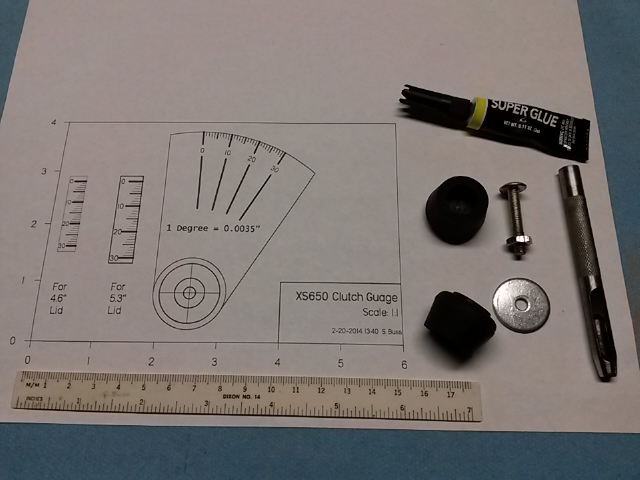

Pic #1 - Here's what you'll need.

A 1:1 scale printout of pic#2, cutting board, knife, scissors, ruler, stupid glue.

1/2" rubber tableleg bumper(s). This will press fit on the worm adjuster screw locknut.

(The XS locknuts came in 13mm and 12mm sizes, but the tableleg bumpers will fit on either.)

A 3/16" hole punch, or if you're skillful, an x-acto knife to carve the holes for the #10 machine screw.

A #10 machine screw, about 1" long, #10 fender washer, #10 nut.

A plastic food container lid, like that found on a tub of cottage cheese, either the 4.6" diameter lid, or the 5.3" diameter lid.

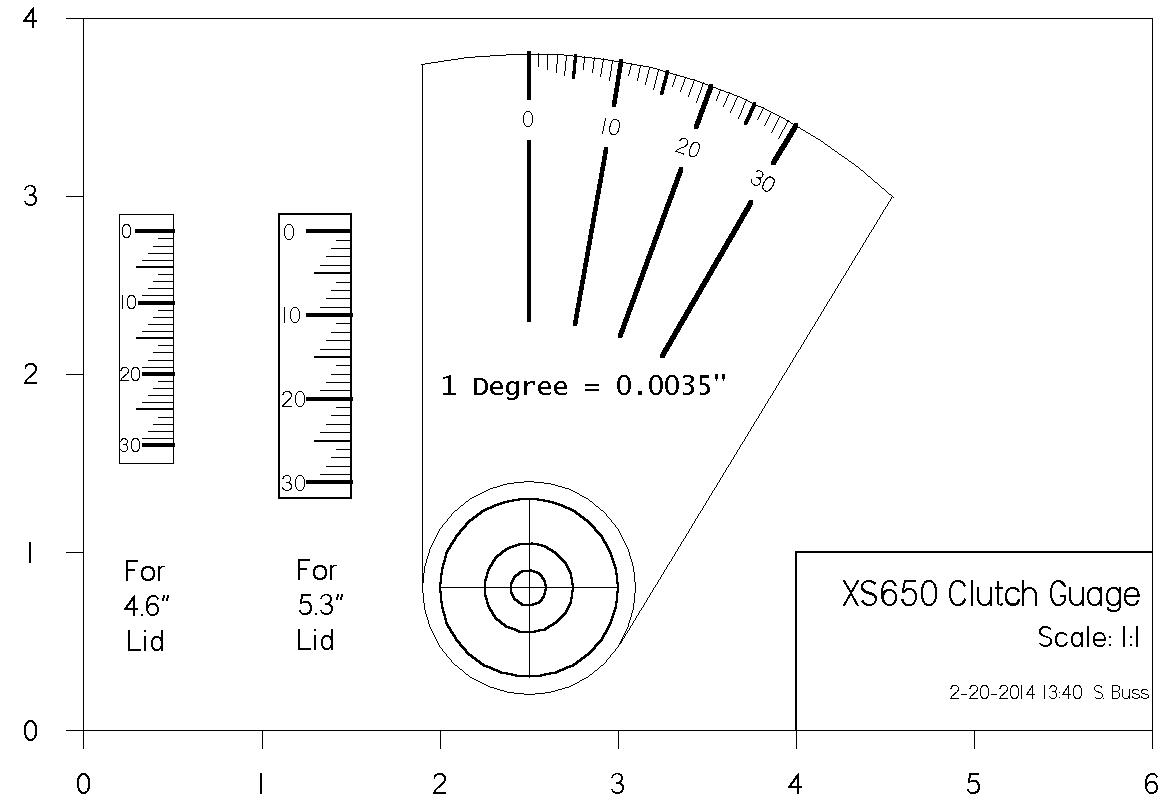

Pic #2 - Degree wheel templates, in JPG format.

Inch scaling lines run down the side and bottom so you can print, measure, and adjust the printer scaling as needed to get true 1:1 scale.

The large fan-shaped degree wheel doesn't need to be scaled, its angles remain the same regardless of scaling.

If you don't have access to a printer, there's an alternative method demonstrated here.

This is a companion piece to the XS650 clutch actuator experiments:

Clutch worm actuator experiments and tidbits

Clutch worm mod testing

Clutch pushrod experiments and tidbits

Clutch cable experiments and tidbits

I've been using a homemade dialgauge adapter to measure worm actuator plunge depths:

Clutch worm depth dialgauge-post90

Clutch worm depth dialgauge-post91

Clutch worm depth dialgauge-post92

But making that dialgauge adapter is a bit involved, so here's a little project that uses simple household appliances and kitchen utensils. Should keep you occupied while snowed-in.

The XS650 clutch worm actuator rotates to create the lateral movement that pushes the clutch pushrod, about 0.0035" per degree of rotation (about 0.003" for the different pitch MikesXS worm mechanism). The amount of rotation can be measured with a homemade degree wheel to estimate how much pushrod travel might be achieved (minus cable and mechanism slack). The amount of rotation is partially influenced by the length of the worm actuator arm, which can be anywhere from 1.2" to 1.8", depending on worm model. The amount of rotation is also influenced by the clutch cable, which, depending on brand and condition, can stretch at different rates.

Pic #1 - Here's what you'll need.

A 1:1 scale printout of pic#2, cutting board, knife, scissors, ruler, stupid glue.

1/2" rubber tableleg bumper(s). This will press fit on the worm adjuster screw locknut.

(The XS locknuts came in 13mm and 12mm sizes, but the tableleg bumpers will fit on either.)

A 3/16" hole punch, or if you're skillful, an x-acto knife to carve the holes for the #10 machine screw.

A #10 machine screw, about 1" long, #10 fender washer, #10 nut.

A plastic food container lid, like that found on a tub of cottage cheese, either the 4.6" diameter lid, or the 5.3" diameter lid.

Pic #2 - Degree wheel templates, in JPG format.

Inch scaling lines run down the side and bottom so you can print, measure, and adjust the printer scaling as needed to get true 1:1 scale.

The large fan-shaped degree wheel doesn't need to be scaled, its angles remain the same regardless of scaling.

If you don't have access to a printer, there's an alternative method demonstrated here.

Last edited: