XS650 E-start

- by now youve probably figured i dont like XS650 starter motors…a lot of energy, time and money went into creating the ‘männer’ machines we all like so much…these looked the part, were reliable, didn’t leak oil and, like everything else, had their weaknesses…the starter motor wasn’t one of them…it didn’t have one, wasn’t meant to…the XS1 cases were round and full, exactly where they should be-the yammy bunny, and stayed that way, until the press’ moaning and bleating compelled Yamaha to compromise with the XS2 and install one

XS1 head showing the triangular front left tappet inspection cover

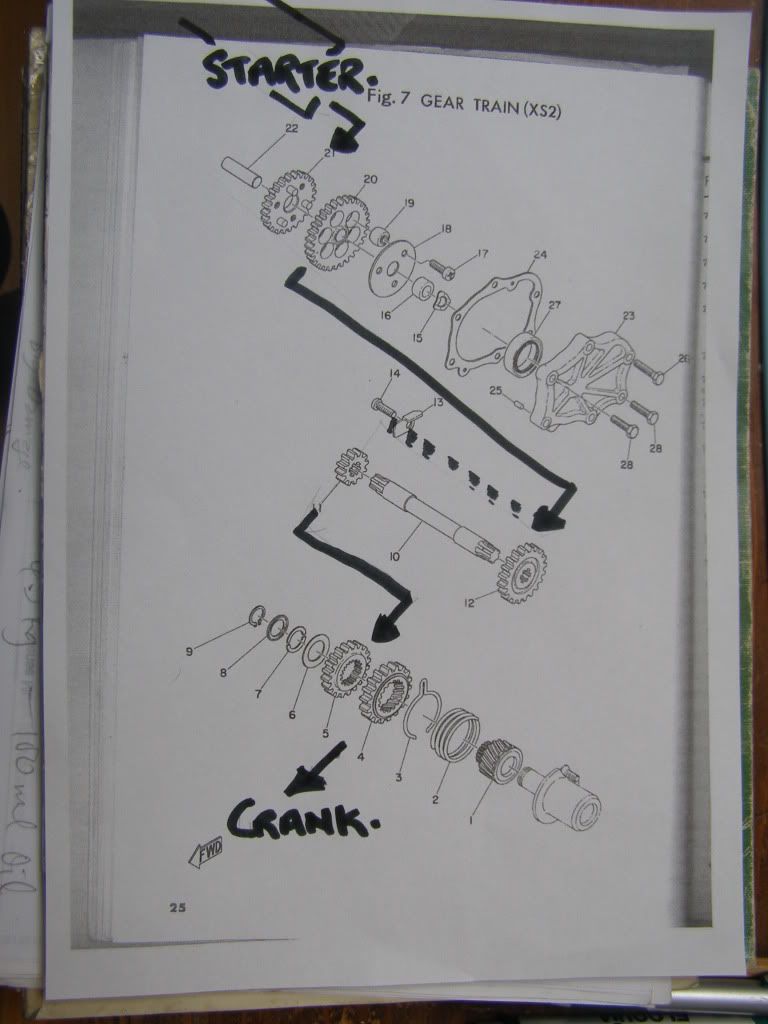

- and compromise it was…tucked away, down in the back 40, a bitch to work on, the starter motor was forced to work its magic through an array of transfer and reduction gears and shafts before connecting with the crankshaft…what a fucking balls-up

- costing 500W and drawing 42A, it meant the battery wasn’t strong enough, and pushed the charging system almost to its limits

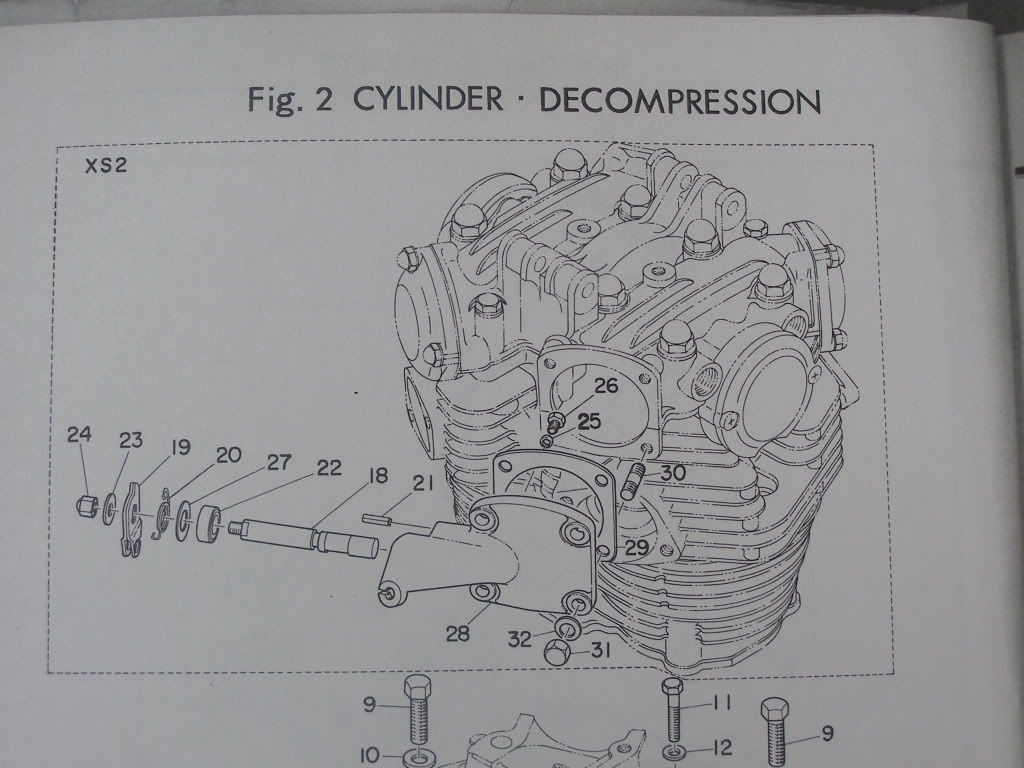

- the answer?...actually, quite ingeniously taking a lesson from the british thumpers, whose market share was getting, well, thumped, Yamaha did a quick redesign of the head and cover, and installed a decompression device…this worked also as the starter button, pull the lever, on the bars, by the clutch, and the starter kicked in

- come the TXA, however, and a larger battery replaced the sexier decompression system, gone forever were the balanced quartet of XS1 triangular valve covers, the front left cover, a decompressive legacy, remaining bulky and square, scarring the face of future XS650 generations

- and that’s progress…the whole proceedure unaesthetically added about 4,5kg and reduced the oil quantity by around 200ml

Problems

- draws heaps of current, 42A, electrical weaknesses can lead to ignition problems, especially with electronic systems

- make sure the starter motor shaft anchor point, in the motor end plate, rotates freely without resistance and that the end plate bushes have no play…there is a tendency to wear these leading to armature wear…the result is increased operating power drain

- if the seal, S 17-28-8, located in the inner end plate leaks the starter will begin to fill with oil and crud, further stressing the electrical system

- the other seal, SD 34-46-10.5, located in the crankcase, sealing to the starter end plate rarely leaks…if the inspection plate is covered in wet oil and crud clean with spray on brake cleaner, scrub with a toothbrush and wash off, go for a ride, you will soon find the source…may be the front sprocket shaft seal leaking because the sprocket is loose-tighten the nut, or the shift shaft or clutch push rod seals

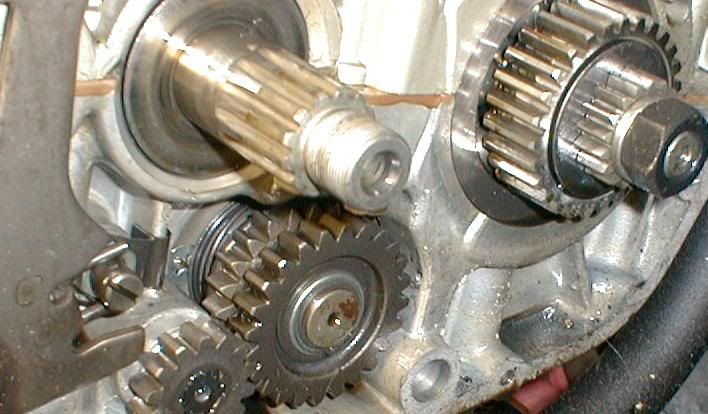

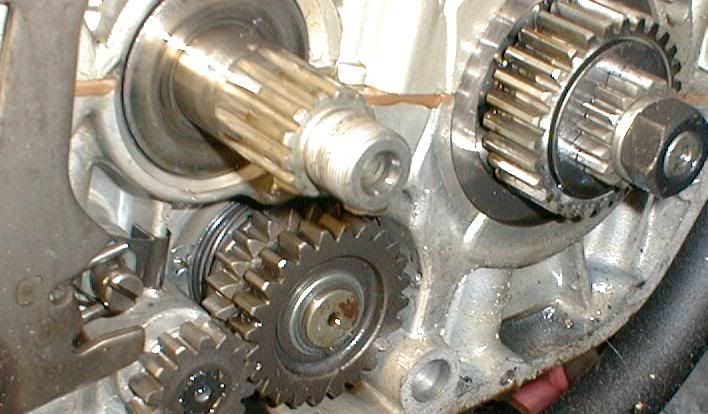

- unlike autos, where the starter-gear meshes with the crank-gear before the starter kicks in, the XS starter rotates at full power before attempting to mesh with the crank…this is the awful ratcheting noise you hear when the transfer gear is worn and clacks on the crank-gear…this full power has 2 side effects, the most noticeable is the wearing of the transfer-gear and, if not fixed, the subsequent wearing of the crank-gear-which cant be fixed, you will find metal filings in your sump…the other effect is, as the transfer-gear whacks into the crank-gear the shock loading has a twisting effect on the crank, the rhs wants to move faster than the lhs, this has been known to manifest itself as deformed crankshaft alignment, sometimes up to 2mm, especially apparent in increased capacity motors when the cranks havent been welded…misfiring exacerbates this problem…the bearings, of course, don’t like this…my crank builder recommends not to use the e-start as a matter of rule on a rebuilt crank before it has had time to settle and to weld the crank as a matter of course

not engaged

engaged

worn ... new

- worn spring clips and springs prevent correct engaging and disengaging of the starter…once the spring-clip has lost its shape and tension, although it can be rebent into shape, the tension generally doesn’t last long, better to replace…when replacing don’t slide down through the receiving groove-instead locate one side first then ease the other side into place

- when working here, unless you are planning to split the cases, dont remove the tab holding the small gear that drives the bendix...this gear sits on a shaft that runs through the gearbox and has another gear loose on the end that is driven by the starter reduction gears...if you try to remove this shaft the gear will fall off, you wont get the shaft out anyway-why make work for yourself

the little gear bottom left

Electrics

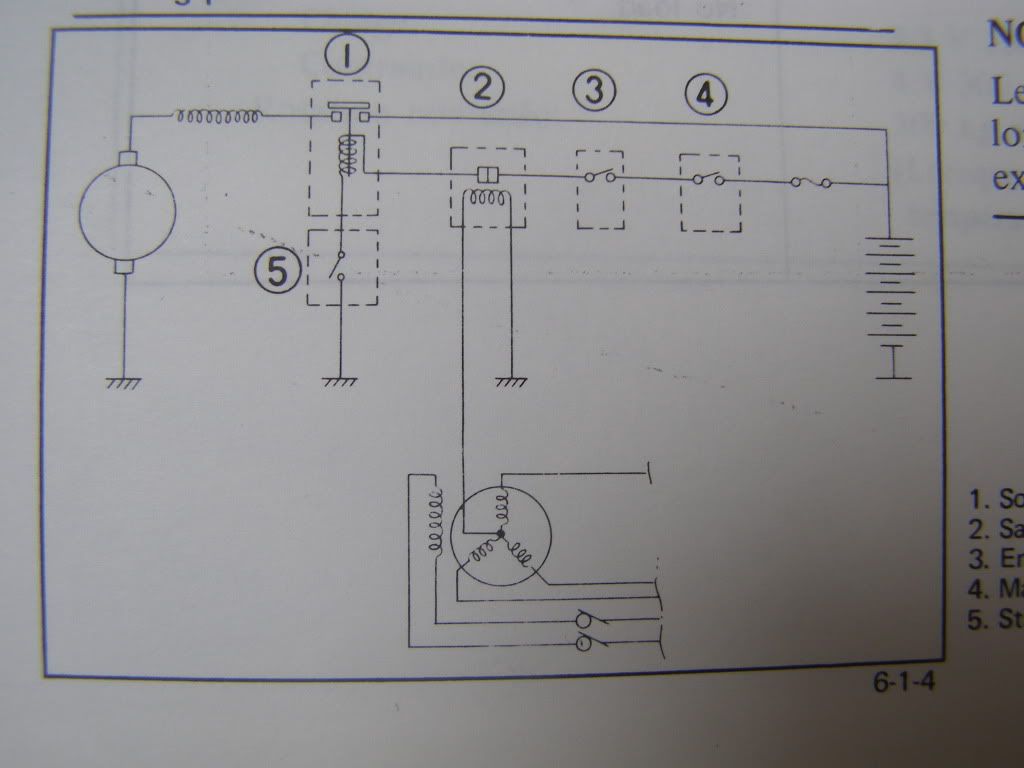

1. Solenoid

2. Safety Relay

3. Kill Switch

4. Main Switch

5. Start Switch

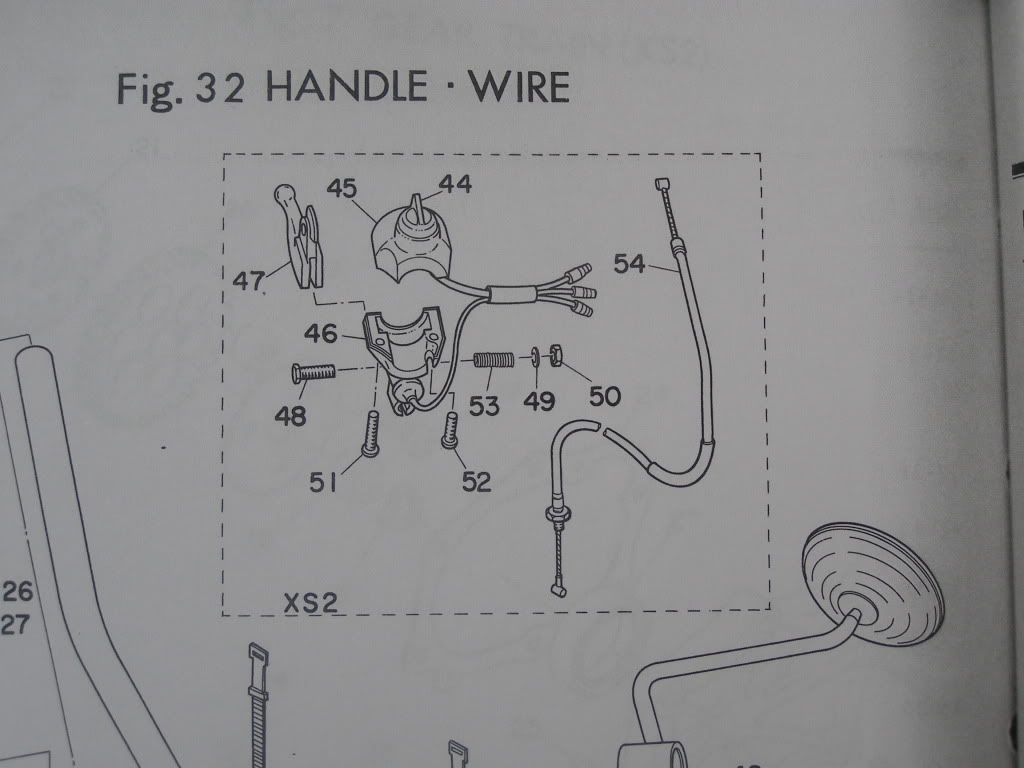

- although the XS2 starter is switched through the decompression lever and subsequent models via a button in the rhs handlebar controls the switch itself simply earths one side of the solenoid or relay allowing a current to pass through it…this sets up a magnetic field that operates the low resistance power feed from the battery to the starter

- the starter, through the labyrinth of reduction and transfer gears, rotates the crankshaft and therefore the alternator, when this is spinning fast enough to generate 4V the yellow cable from the alternater feeds the safety relay enough current to open the contact which automatically shuts the starter circuit down

safety relays..top right non US, bottom right US

starter relay

solenoid

Problems

- weak battery

- weak charging system..worn alternator brushes

- dirty electrical connections

- loose electrical connections

- broken wires

- worn starter motor brushes

- burnt contact in the solenoid…short contacts with a heavy screw driver

- safety relay not operating…bypass battery to solenoid

- system not earthing properly...check especially starter button, just because you earth to the handlebar doesnt mean the bar is earthed either-rubber mounted

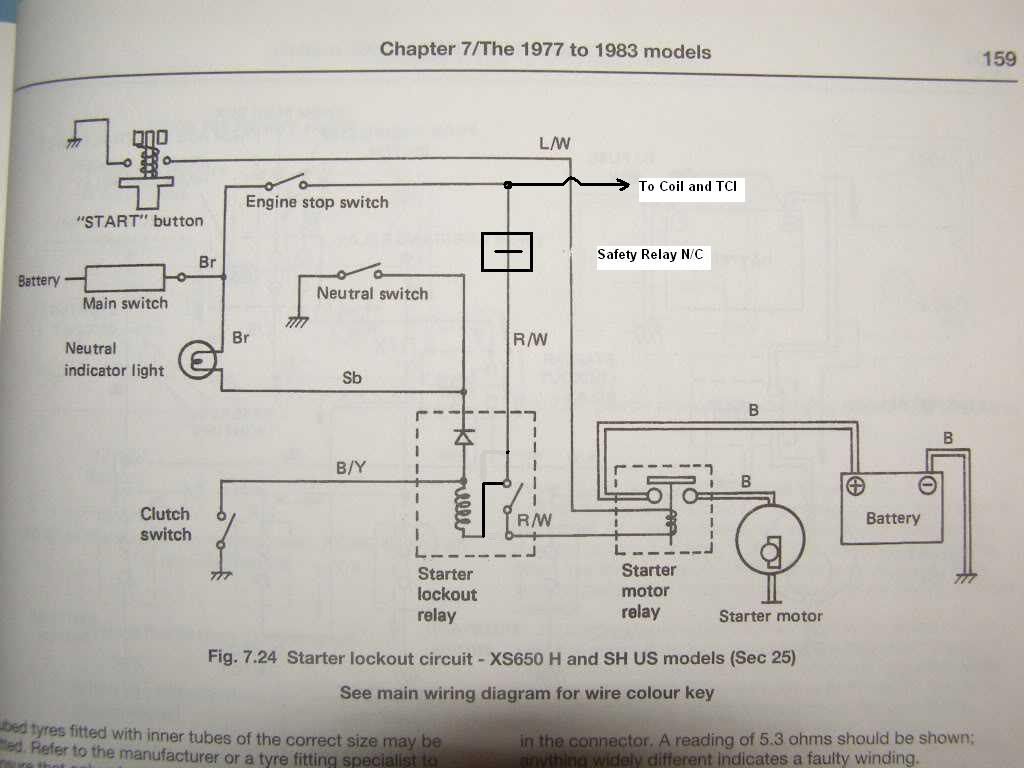

- starting circuits

XS650 H-SH ...corrected version-hattip pamopete

- clutch and neutral switches prevent starter operation in gear

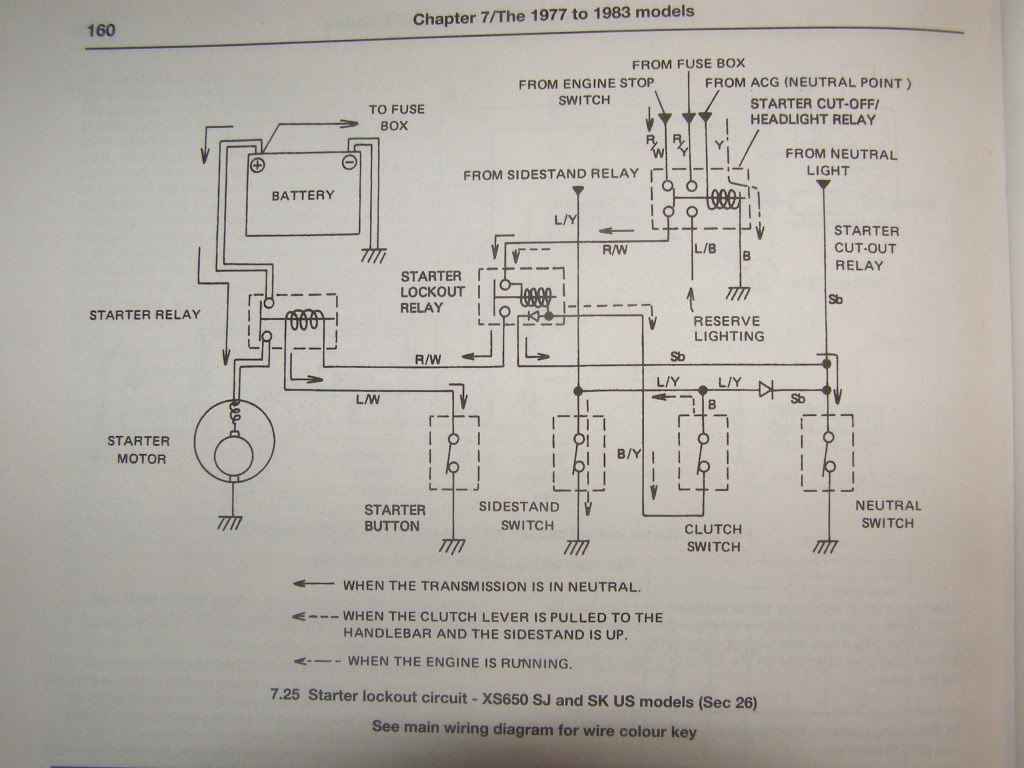

XS650 SJ-SK

- add ons are sidestand switch, on the sidestand and a starter cut-off relay, attached to the safety relay

- by now youve probably figured i dont like XS650 starter motors…a lot of energy, time and money went into creating the ‘männer’ machines we all like so much…these looked the part, were reliable, didn’t leak oil and, like everything else, had their weaknesses…the starter motor wasn’t one of them…it didn’t have one, wasn’t meant to…the XS1 cases were round and full, exactly where they should be-the yammy bunny, and stayed that way, until the press’ moaning and bleating compelled Yamaha to compromise with the XS2 and install one

XS1 head showing the triangular front left tappet inspection cover

- and compromise it was…tucked away, down in the back 40, a bitch to work on, the starter motor was forced to work its magic through an array of transfer and reduction gears and shafts before connecting with the crankshaft…what a fucking balls-up

- costing 500W and drawing 42A, it meant the battery wasn’t strong enough, and pushed the charging system almost to its limits

- the answer?...actually, quite ingeniously taking a lesson from the british thumpers, whose market share was getting, well, thumped, Yamaha did a quick redesign of the head and cover, and installed a decompression device…this worked also as the starter button, pull the lever, on the bars, by the clutch, and the starter kicked in

- come the TXA, however, and a larger battery replaced the sexier decompression system, gone forever were the balanced quartet of XS1 triangular valve covers, the front left cover, a decompressive legacy, remaining bulky and square, scarring the face of future XS650 generations

- and that’s progress…the whole proceedure unaesthetically added about 4,5kg and reduced the oil quantity by around 200ml

Problems

- draws heaps of current, 42A, electrical weaknesses can lead to ignition problems, especially with electronic systems

- make sure the starter motor shaft anchor point, in the motor end plate, rotates freely without resistance and that the end plate bushes have no play…there is a tendency to wear these leading to armature wear…the result is increased operating power drain

- if the seal, S 17-28-8, located in the inner end plate leaks the starter will begin to fill with oil and crud, further stressing the electrical system

- the other seal, SD 34-46-10.5, located in the crankcase, sealing to the starter end plate rarely leaks…if the inspection plate is covered in wet oil and crud clean with spray on brake cleaner, scrub with a toothbrush and wash off, go for a ride, you will soon find the source…may be the front sprocket shaft seal leaking because the sprocket is loose-tighten the nut, or the shift shaft or clutch push rod seals

- unlike autos, where the starter-gear meshes with the crank-gear before the starter kicks in, the XS starter rotates at full power before attempting to mesh with the crank…this is the awful ratcheting noise you hear when the transfer gear is worn and clacks on the crank-gear…this full power has 2 side effects, the most noticeable is the wearing of the transfer-gear and, if not fixed, the subsequent wearing of the crank-gear-which cant be fixed, you will find metal filings in your sump…the other effect is, as the transfer-gear whacks into the crank-gear the shock loading has a twisting effect on the crank, the rhs wants to move faster than the lhs, this has been known to manifest itself as deformed crankshaft alignment, sometimes up to 2mm, especially apparent in increased capacity motors when the cranks havent been welded…misfiring exacerbates this problem…the bearings, of course, don’t like this…my crank builder recommends not to use the e-start as a matter of rule on a rebuilt crank before it has had time to settle and to weld the crank as a matter of course

not engaged

engaged

worn ... new

- worn spring clips and springs prevent correct engaging and disengaging of the starter…once the spring-clip has lost its shape and tension, although it can be rebent into shape, the tension generally doesn’t last long, better to replace…when replacing don’t slide down through the receiving groove-instead locate one side first then ease the other side into place

- when working here, unless you are planning to split the cases, dont remove the tab holding the small gear that drives the bendix...this gear sits on a shaft that runs through the gearbox and has another gear loose on the end that is driven by the starter reduction gears...if you try to remove this shaft the gear will fall off, you wont get the shaft out anyway-why make work for yourself

the little gear bottom left

Electrics

1. Solenoid

2. Safety Relay

3. Kill Switch

4. Main Switch

5. Start Switch

- although the XS2 starter is switched through the decompression lever and subsequent models via a button in the rhs handlebar controls the switch itself simply earths one side of the solenoid or relay allowing a current to pass through it…this sets up a magnetic field that operates the low resistance power feed from the battery to the starter

- the starter, through the labyrinth of reduction and transfer gears, rotates the crankshaft and therefore the alternator, when this is spinning fast enough to generate 4V the yellow cable from the alternater feeds the safety relay enough current to open the contact which automatically shuts the starter circuit down

safety relays..top right non US, bottom right US

starter relay

solenoid

Problems

- weak battery

- weak charging system..worn alternator brushes

- dirty electrical connections

- loose electrical connections

- broken wires

- worn starter motor brushes

- burnt contact in the solenoid…short contacts with a heavy screw driver

- safety relay not operating…bypass battery to solenoid

- system not earthing properly...check especially starter button, just because you earth to the handlebar doesnt mean the bar is earthed either-rubber mounted

- starting circuits

XS650 H-SH ...corrected version-hattip pamopete

- clutch and neutral switches prevent starter operation in gear

XS650 SJ-SK

- add ons are sidestand switch, on the sidestand and a starter cut-off relay, attached to the safety relay

Last edited: