Noted, thanx srust58.

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Zinc Electroplating

- Thread starter grepper

- Start date

-

- Tags

- how to restoration

Grepper? You still with us? Your last login was back in mid-June.

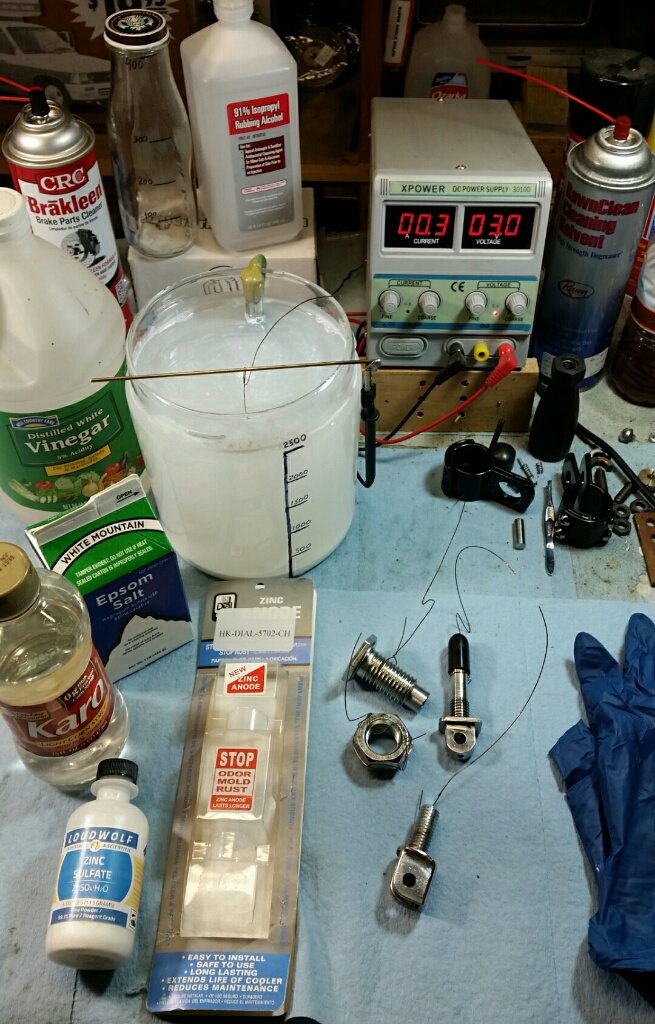

Anyways, gave this "Zinc Electroplating" procedure a try on my "Centerstand Lift Assist" parts.

Cleaned them up in preparation for plating.

I reduced the recipe in post #1 by 1/2, making just over a half gallon of plating solution.

Ran the plate process at 3volts, 300ma, 30 minutes.

The plated parts come out with a white scum surface, which has to be water rinse brushed off.

After drying, the remaining thin white coating is polished off with #0000 steel wool.

They came out fairly shiny.

Following this recipe/procedure, I measured the Zinc plating at about 1 micron (40 microinches).

Cleaned up the parts, and ran them again for two more cycles.

The plating is thin enuff to not interfere with threads and close-fitting parts.

It's also thin enuff to show surface blemishes. So, expect to retain the original surface roughness, but it'll be shinier.

Only about half the Zinc Sulfate would dissolve, not sure if the recipe should be adjusted.

The way that the white scum builds up on the surface during plating, I don't think that sessions longer than 30 minutes would be advised. So, plan on multiple cycles if you want thicker plating...

Anyways, gave this "Zinc Electroplating" procedure a try on my "Centerstand Lift Assist" parts.

Cleaned them up in preparation for plating.

I reduced the recipe in post #1 by 1/2, making just over a half gallon of plating solution.

Ran the plate process at 3volts, 300ma, 30 minutes.

The plated parts come out with a white scum surface, which has to be water rinse brushed off.

After drying, the remaining thin white coating is polished off with #0000 steel wool.

They came out fairly shiny.

Following this recipe/procedure, I measured the Zinc plating at about 1 micron (40 microinches).

Cleaned up the parts, and ran them again for two more cycles.

The plating is thin enuff to not interfere with threads and close-fitting parts.

It's also thin enuff to show surface blemishes. So, expect to retain the original surface roughness, but it'll be shinier.

Only about half the Zinc Sulfate would dissolve, not sure if the recipe should be adjusted.

The way that the white scum builds up on the surface during plating, I don't think that sessions longer than 30 minutes would be advised. So, plan on multiple cycles if you want thicker plating...

Hi 2M good result. How much of the corn syrup did you use. Grepper was a bit vague on that. My Zinc plating efforts always need a buff to brighten. Industrial electro zinc plating is bright out of the tank, does anyone know what the trick is?

Watch out it, the outcome is quite satisfying and it wasn't long before long I was looking for stuff to plate.

Watch out it, the outcome is quite satisfying and it wasn't long before long I was looking for stuff to plate.

Never zinc plated but this might help. search keywords were zinc plating and smut.

http://www.materialstoday.com/metal...ubleshooting-common-problems-in-zinc-plating/

http://www.materialstoday.com/metal...ubleshooting-common-problems-in-zinc-plating/

Hi 2M good result. How much of the corn syrup did you use. Grepper was a bit vague on that.

Thanx, Signal. For his 4.5litre mix, he just said 1/3rd bottle. The Karo syrup comes in 16oz bottles, so that would be about 5oz. I used 1/6th bottle, about 2.5 Oz.

Karo syrup is corn syrup, mostly maltose, one of the six sugars. I have no idea if that particular selection of sugar is important or not, but I was careful in selecting one of the offerings that didn't have other sugars (hi-fructose), colorings (caramel), flavorings (vanilla). A generic "corn syrup" would probably suffice.

Now I need to stock up on pancakes and waffles, to make use of that syrup.

My Zinc plating efforts always need a buff to brighten. Industrial electro zinc plating is bright out of the tank, does anyone know what the trick is?

I have a fine-wire (0.0035") carding wheel, used for between-process buffing during hot-water bluing of firearm parts. I thought about using it, but decided against for fear of contaminating it with the zinc stuff.

Looking up zinc plating formulas and processes, like in gggGary's link, is another black hole. I think we could divide these into two groups, industrial and hobbyist.

The industrial has to deal with large volumes and sizes of gunky stuff, and goes to great lengths to avoid manual labor, letting the chemical baths do the work.

The hobbyists are no strangers to manual meticulous prep work, and would prefer to avoid using dangerous stuff, like the cyanides. This opens the door to alternative methods, with various compromises.

Well, that's my take on it.

Watch out it, the outcome is quite satisfying and it wasn't long before long I was looking for stuff to plate.

Yeah, thanx for the warning. I saved the "mix" for future stuff, or to give it to somebody (DogBunny???)...

...search keywords were ... smut.

Uh, oh. Expect interesting items in your email's inbox now...

Oddly no, I think smut is the technical term for unwanted rough deposits on plating work. Doesn't the term come from the smudging left on lantern glass from poorly trimmed wicks? LOL. Also some ear corn disease is called smut.

...Watch out it, the outcome is quite satisfying and it wasn't long before long I was looking for stuff to plate.

Sure 'nuff, my kickstart boss was pretty cruddy, grey, mottled, with rust spots.

Ran it thru the process, much better.

Also found another writeup on this particular formulae/process:

http://www.southsandia.com/forum/website/zincplating.html

GunnerB52

XS650 Member

- Messages

- 9

- Reaction score

- 0

- Points

- 3

Thanks grepper for posting this process, not particularly difficult to do and end up with parts that look much better if not new. I have used an electrolysis process similar to this for rust removal, that has borax laundry detergent and water for the solution and steel bars for the anodes. Used a battery charger for a power supply. Derusts parts well and even reverses some minor pitting. Thanks 2M for the link you posted.

Just to keep this conversation going, I want to ask these questions. How do these platings hold up over time? Doesn't zinc have a form of corrosion of its own? What is the stock plating on the XS exhaust flanges, shifter, kick starter, brake arm?

Scott

Scott

Scott, the rabbit hole is deep. Lookup ASTM B-633 for specifics.

According to the industry, 5 micron plating thickness is the minimum for mild indoor service, which may be for 10-15 years, or more.

The surface corrosion is called "zinc rust" and "white rust". Conversion coatings are supposed to eliminate that.

If I recall, and subject to debate, the showy hardparts, shift lever, kickstart, and exhaust flanges were done in the oldschool hexavalent (now disallowed) chrome plate. Other parts, including brake rod and stay, and wheel spokes were cadmium plated.

According to the industry, 5 micron plating thickness is the minimum for mild indoor service, which may be for 10-15 years, or more.

The surface corrosion is called "zinc rust" and "white rust". Conversion coatings are supposed to eliminate that.

If I recall, and subject to debate, the showy hardparts, shift lever, kickstart, and exhaust flanges were done in the oldschool hexavalent (now disallowed) chrome plate. Other parts, including brake rod and stay, and wheel spokes were cadmium plated.

Thanks, 2M. That original plating on the exhaust flanges, kick starter and shift pedal is the nicest, long lasting, easily cleanable plating that I have ever found on a motorcycle. Parts that I have found on newer Yamahas do not compare with the plating that I have found on this old 650. I cleaned these old parts with a soaking in vinegar, brushed with a brass brush, washed and chrome polished and waxed, they came out real nice. Rubbing with aluminum foil did not work too well on that plating, gave a dull surface with an undesirable color.

Scott

Scott