-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Part identity help !

- Thread starter Biggles19

- Start date

Here's a little tip that will help in the future...

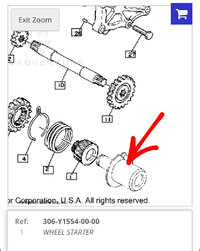

Anytime you see a part on a parts list that's drawn in lightly... or in a dashed line, it means it's part of the larger assembly. In this case, the lower crankcase half. It was either cast in or pressed in at the factory. Far as I know, it's not replaceable. Never seen someone remove it either... you sure it's missing?

Anytime you see a part on a parts list that's drawn in lightly... or in a dashed line, it means it's part of the larger assembly. In this case, the lower crankcase half. It was either cast in or pressed in at the factory. Far as I know, it's not replaceable. Never seen someone remove it either... you sure it's missing?

100% missing mate got a nice round hole for itHere's a little tip that will help in the future...

Anytime you see a part on a parts list that's drawn in lightly... or in a dashed line, it means it's part of the larger assembly. In this case, the lower crankcase half. It was either cast in or pressed in at the factory. Far as I know, it's not replaceable. Never seen someone remove it either... you sure it's missing?

View attachment 323369

One of the case half studs.... nut is missing.

Hawkeye

Engine is still out of bike not yet back together just trying to identify the part I’m missing

There is a good thread on how to remove that post somewhere, but I can't find it. I did find this:HELP PLEASE

Started motor install is almost done however I don’t have the part I have highlighted and can’t find a name for the part to ask my dealer who is breaking a xs650 engine if he still has it.

Many thanks as always folks

https://www.xs650.com/threads/starter-gear-a-case-post-removal.63073/

In any case, I've removed a few of them. It's not easy, but can be done. I've also been thwarted a couple of times, and gave up. It's really in there.

My method is to split the cases, heat the case half in an oven, and hammer it from the inside with a big hammer and a drift. A big reason why it isn't easy, is because you can't get a straight shot at it with the drift.

I have at least one useless case that I can try to get it out of for you if you run out of options.

There is no part number, but a name would be starter gear boss or starter gear post.

You sure are an absolute gent ! I have spent all day looking that it’s really been bothering me !  thanks a lot I’m going to head to a bike shop tomorrow with hope it’s a bolt or part but it’s not looking likely by what you have said !

thanks a lot I’m going to head to a bike shop tomorrow with hope it’s a bolt or part but it’s not looking likely by what you have said !

For anyone following we are going to see what it will take to make this parta lot of picture and success / fail (hope not) to follow cheers all

What I can se on the forum it is shrink fit in there .Making one in a shop can be difficult to get the right

tolerances outer and inner dimensions. As well as other dimensions since you don't have anything to measure on

And will cost some.

Last time i bought blocks I believe I payed ca $ 100 for Usable both halves including the missing part

A defect block will be cheaper

New Zealand Mr Signal has a method getting it out and in Out is no problem force and angle grinder

if nothing else

Problem is getting it in .Ice Cooled it still can need some force to get in.

Assuming you are trying without taking it apart

Mr DogBunny has them # 8

Motor will come back out again and yes will be using heat and cooling I think it’s more the curious to give it a go, nothing gained otherwise your very right on seeing if it can be done failing that I may just be asking @DogBunny if he wants to ship one to UK very kindlyWhat I can se on the forum it is shrink fit in there .Making one in a shop can be difficult to get the right

tolerances outer and inner dimensions. As well as other dimensions since you don't have anything to measure on

And will cost some.

Last time i bought blocks I believe I payed ca $ 100 for Usable both halves including the missing part

A defect block will be cheaper

New Zealand Mr Signal has a method getting it out and in Out is no problem force and angle grinder

if nothing else

Problem is getting it in .Ice Cooled it still can need some force to get in.

Assuming you are trying without taking it apart

Mr DogBunny has them # 8

Exactly.What I can se on the forum it is shrink fit in there .Making one in a shop can be difficult to get the right

tolerances outer and inner dimensions. As well as other dimensions since you don't have anything to measure on

And will cost some.

Last time i bought blocks I believe I payed ca $ 100 for Usable both halves including the missing part

A defect block will be cheaper

New Zealand Mr Signal has a method getting it out and in Out is no problem force and angle grinder

if nothing else

Problem is getting it in .Ice Cooled it still can need some force to get in.

Assuming you are trying without taking it apart

Mr DogBunny has them # 8

It's a somewhat complicated piece. I don't see how you could make one unless you had another one in hand to take measurements from... and if you had one in hand, you wouldn't need to make one any more.For anyone following we are going to see what it will take to make this parta lot of picture and success / fail (hope not) to follow cheers all

If it was me I would consider doing it with motor still in place ..

If Mr Signal has info on how hard it fits

Mildly warming the engine to something not over working engine temperature hot air gun or so and

cooling the part .. there are different ways It might slide in .

If Mr Signal has info on how hard it fits

Mildly warming the engine to something not over working engine temperature hot air gun or so and

cooling the part .. there are different ways It might slide in .

@DogBunny what I be looking for you post one out the UK as a back up option your the only gent I found that may have one up for grabs this farExactly.

PM sent......@DogBunny what I be looking for you post one out the UK as a back up option your the only gent I found that may have one up for grabs this far

Sorry no practice at removal or install with motor in situ. For removal the case does require considerable time in the bbq (heat) for them to fall out.

To remove

I would be inclined to remove the motor and split the cases . Sometimes the long way is a shortcut, if you try to drive the post out out in situ and it cocks over and jams you will need to take the motor out to fix it anyway.

To install

I have only done this twice and with the case hot and the post from the freezer it only required a gentle squeeze in the press. I did make a crude alinement guide that screwed into the fixing screw hole to aline post cutout with the hole.

Have a go at installing it in situ, get the post really cold and heat the case as much as you can. My thinking would be to use a long clamp like joiners use to press the push in. Also make a guide even an old 6mm cap screw with the head cut off would do.

If it doesn't work you haven't lost anything just pull the motor and have another go at it.

Please let us know how you get on.

To remove

I would be inclined to remove the motor and split the cases . Sometimes the long way is a shortcut, if you try to drive the post out out in situ and it cocks over and jams you will need to take the motor out to fix it anyway.

To install

I have only done this twice and with the case hot and the post from the freezer it only required a gentle squeeze in the press. I did make a crude alinement guide that screwed into the fixing screw hole to aline post cutout with the hole.

Have a go at installing it in situ, get the post really cold and heat the case as much as you can. My thinking would be to use a long clamp like joiners use to press the push in. Also make a guide even an old 6mm cap screw with the head cut off would do.

If it doesn't work you haven't lost anything just pull the motor and have another go at it.

Please let us know how you get on.

I'm here to confirm that the barbecue method of removal is a bit of genius. Nothing to it, and for me, it hardly took any time for the boss to fall out by itself.They come out easily. Prop case on side in BBQ starter post down. Make sure enough room for post to fall clear of case. Light BBQ close lid and wait for clunk of post falling out.

To install make alignment tool to guide post into correct position for retaining screw. I use a bit of ally rod with a 6mm thread. Heat case as before, cool post in freezer. When ready drop post into position.

One caveat: I have a permanent pedestal grill with a plumbed-in natural gas supply from the city. The type that uses permanent ceramic briquettes. My grill and briquettes are now polluted with oil drippings from the engine case, making it unsuitable for cooking food. I knew this would happen, but that grill is on its absolute last legs, and I don't really use it any more anyways since transitioning away from animal protein.

Here's the boss, now on it's way to Biggles. It emerged from the grill a little blued from oil smoke, but it polished right up.

BTW, I would never do the BBQ method if I intended to re-use the case. If I wanted to re-use the case, I would use an oven. Somewhere, there's a thread that covers how hot you can safely heat an aluminum engine case or head.

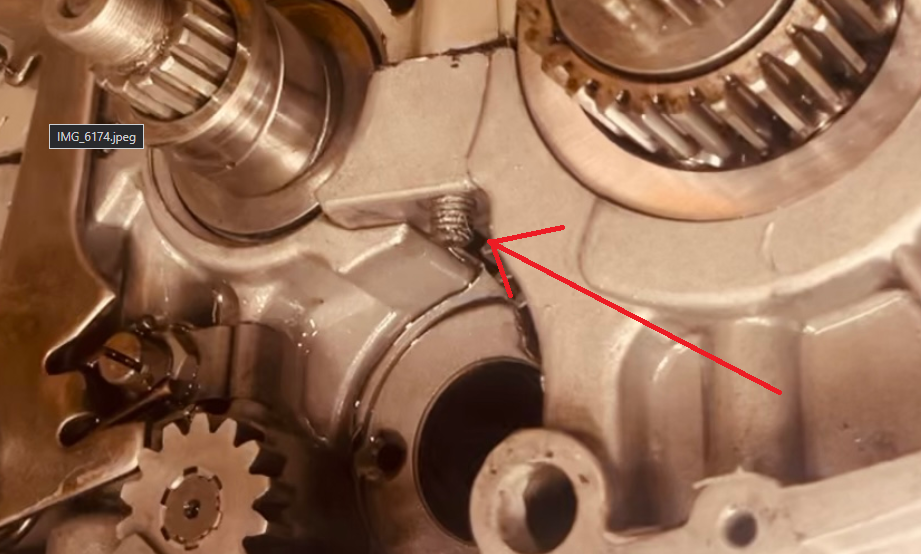

Earlier, I wrote that I have removed starter gear bosses from the rear, using heat, a big hammer, and a drift, but it's not easy because you can't get a straight shot at the back of the boss. This pic shows what I mean.

Cutting it out would also be extremely difficult. You'd really need a huge stationary horizontal band saw to get to it.

This little bit of edge on the boss is the only thing you can attack with your big hammer and drift. You're hitting it at an angle, so your simultaneously cocking it in it's recessed case socket hole as you try to drive it out.

So, the way to go is high-heat BBQ or oven.

Similar threads

- Replies

- 6

- Views

- 169