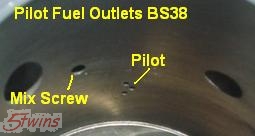

I've done up two sets of these '76-'77 carbs, on two different bikes, and neither set needed more than one up on the pilots. I think maybe you should check the carbs again, maybe the idle circuits are partially plugged. There are 4 tiny holes that deliver the pilot jet fuel/air mix into the main bore of the carb. I'd make sure they're all clear.

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1976 Running Rich

- Thread starter Wilsonsk

- Start date

Wilsonsk

XS650 Addict

I think you may be right, something has been wonky with the bottom end for a while, the cold blooded thing, when I first got it running, after I did the carbs, it would fire instantly on choke, no throttle, and only need maybe 10 seconds of choke and be pretty rideable right away, now it’s got to be HOT to run good, it does run pretty good then. If I understood that guys explanation, the mixture screw hole is after the butterflies, and is there for idle, once the butterflies start to move, then airflow increases, pulling more from the mixture screw hole as well as pulling gas from the pilot holes, I’ve there is not enough (or any) available at the pilot holes, it falls on its face?I've done up two sets of these '76-'77 carbs, on two different bikes, and neither set needed more than one up on the pilots. I think maybe you should check the carbs again, maybe the idle circuits are partially plugged. There are 4 tiny holes that deliver the pilot jet fuel/air mix into the main bore of the carb. I'd make sure they're all clear.

View attachment 250795

Do you have access to compressed air? Because that's what you really need to blow through the pilot jet passageways to insure they're clear. I use a blow gun with a rubber tip mostly, but I also have assorted sizes of needle tips that I can stick down into passageways .....

Wilsonsk

XS650 Addict

I have compressed air, where did you get the needle tips?

EDIT: I have some needle tips on order.

What’s the best direction to blow out the passages? Through the mixture screw hole? From the bottom with the bowl off ? From the carb bore back through the ports? All of the above?

EDIT: I have some needle tips on order.

What’s the best direction to blow out the passages? Through the mixture screw hole? From the bottom with the bowl off ? From the carb bore back through the ports? All of the above?

Last edited:

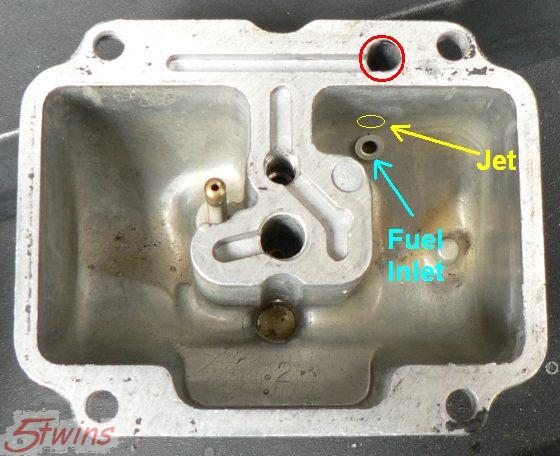

Well, basically, all of the above, lol. The fuel/air mix from the pilot jet enters the carb body through a small hole on the bottom of the body at the center near the front .....

So, to flush the passageway out, remove the bowl and the mix screw. I use that carb cleaner in a can with the little red straw. Spray the cleaner into the hole while blocking the mix screw hole on the outside, and it should come out the 4 little holes in the main bore. Block the little mix screw hole too and it will come out the 3 little holes. Block them and it will come out the mix screw hole. Then, to "back-flush" the circuit, block the 4 little holes and squirt cleaner into the mix screw hole from the outside. It should come out the pilot inlet on the bottom of the carb.

After squirting the carb cleaner in, give it a blast of compressed air to really blow it through. That tapered rubber tip on the blow gun works well for this. By alternately flushing and back-flushing, and blocking some of the inlet holes then others, you can come at the circuit from several different directions and should be able to get it nice and clean. Once I'm done with the carb cleaner, I flush through with WD40 to clean out any carb cleaner residue. That stuff is very caustic so I don't like to leave any in the carb body passageways if possible. Needless to say, you also want to keep it away from any rubber parts as it can destroy them, in particular, the diaphragms. Soak them down with carb cleaner and they'll shrivel up like a used condom, lol. I'll also add that it's pretty easy to verify that the little mix screw hole is clear into the main bore just by looking into the mix screw hole from the outside. Being a straight shot into the main bore, you should be able to see right into it. This is a BS34 but the principal is the same .....

So, to flush the passageway out, remove the bowl and the mix screw. I use that carb cleaner in a can with the little red straw. Spray the cleaner into the hole while blocking the mix screw hole on the outside, and it should come out the 4 little holes in the main bore. Block the little mix screw hole too and it will come out the 3 little holes. Block them and it will come out the mix screw hole. Then, to "back-flush" the circuit, block the 4 little holes and squirt cleaner into the mix screw hole from the outside. It should come out the pilot inlet on the bottom of the carb.

After squirting the carb cleaner in, give it a blast of compressed air to really blow it through. That tapered rubber tip on the blow gun works well for this. By alternately flushing and back-flushing, and blocking some of the inlet holes then others, you can come at the circuit from several different directions and should be able to get it nice and clean. Once I'm done with the carb cleaner, I flush through with WD40 to clean out any carb cleaner residue. That stuff is very caustic so I don't like to leave any in the carb body passageways if possible. Needless to say, you also want to keep it away from any rubber parts as it can destroy them, in particular, the diaphragms. Soak them down with carb cleaner and they'll shrivel up like a used condom, lol. I'll also add that it's pretty easy to verify that the little mix screw hole is clear into the main bore just by looking into the mix screw hole from the outside. Being a straight shot into the main bore, you should be able to see right into it. This is a BS34 but the principal is the same .....

Wilsonsk

XS650 Addict

Thanks for being very detailed!! Since I put the pods on there is a lot less to taking the carbs off. I'll tackle this in the next day or 2.Well, basically, all of the above, lol. The fuel/air mix from the pilot jet enters the carb body through a small hole on the bottom of the body at the center near the front .....

So, to flush the passageway out, remove the bowl and the mix screw. I use that carb cleaner in a can with the little red straw. Spray the cleaner into the hole while blocking the mix screw hole on the outside, and it should come out the 4 little holes in the main bore. Block the little mix screw hole too and it will come out the 3 little holes. Block them and it will come out the mix screw hole. Then, to "back-flush" the circuit, block the 4 little holes and squirt cleaner into the mix screw hole from the outside. It should come out the pilot inlet on the bottom of the carb.

After squirting the carb cleaner in, give it a blast of compressed air to really blow it through. That tapered rubber tip on the blow gun works well for this. By alternately flushing and back-flushing, and blocking some of the inlet holes then others, you can come at the circuit from several different directions and should be able to get it nice and clean. Once I'm done with the carb cleaner, I flush through with WD40 to clean out any carb cleaner residue. That stuff is very caustic so I don't like to leave any in the carb body passageways if possible. Needless to say, you also want to keep it away from any rubber parts as it can destroy them, in particular, the diaphragms. Soak them down with carb cleaner and they'll shrivel up like a used condom, lol. I'll also add that it's pretty easy to verify that the little mix screw hole is clear into the main bore just by looking into the mix screw hole from the outside. Being a straight shot into the main bore, you should be able to see right into it. This is a BS34 but the principal is the same .....

Wilsonsk

XS650 Addict

Got the carbs off, I didn’t have my phone with me and I need to get them on the bench with better light, but I saw two things in the quick check I did, I sprayed from the pilot port in the bowl area bottom of the carb. I got a lot out of the 3 small holes and the mixture hole on both sides. Too much to see if it’s coming out of all 3 little holes on both sides, but it’s coming out of both areas, both carbs, pretty freely. I was holding the throttle butterflies open so I could see, when I let them close against the idle stop where I had last set it (It was idling at 1200-1300 hot yesterday), I noticed that the right one was open enough that I could see one of the 3 pilot holes, the left side was completely closed, I couldn’t see any of the holes (other than the mixture screw hole). When I cleaned the carbs the first time, I didn’t touch the sync screw, just separated the carbs and put them back together when I was done. I figured the carbs were synced before and should still be synced. I adjusted them now so visually they are open the same amount. I need to finish flushing the pilot circuit tomorrow and then I’ll get them back on.

I went back out and got better lighting, definitely good flow out of all 3 and the mixture screw hole on both sides. I blew them out with air then flooded with WD40. I’ll keep flushing in all directions.

I also set my floats to 25mm, the last time I adjusted them, they were on the bike, not easy to do upside down, and they were a couple mm low when I checked with a clear tube. They were at about 27mm so I set them to 25mm, I'll check the actual level when I get them back on.

Also just went out and bench synced the carbs using .5mm wire and put the 27.5 pilots back in, theoretically, if I have resolved whatever gremlins I've been fighting, they should be correct now.

I went back out and got better lighting, definitely good flow out of all 3 and the mixture screw hole on both sides. I blew them out with air then flooded with WD40. I’ll keep flushing in all directions.

I also set my floats to 25mm, the last time I adjusted them, they were on the bike, not easy to do upside down, and they were a couple mm low when I checked with a clear tube. They were at about 27mm so I set them to 25mm, I'll check the actual level when I get them back on.

Also just went out and bench synced the carbs using .5mm wire and put the 27.5 pilots back in, theoretically, if I have resolved whatever gremlins I've been fighting, they should be correct now.

Last edited:

Wilsonsk

XS650 Addict

Put the carbs back on, I haven't checked real float level yet, with completely dry carbs it spit and sputtered on start-up, after 30 seconds or so, the idle was about 2500, I hadn't touched the idle since a couple days ago, I think that's a good sign. I backed that down to 1200-1300 and let it warm up for 3 or 4 minutes. I started on the mixture screws, this is the first time I've messed with them that I actually got response like I've read about, peaking the idle speed within about a half turn, then resetting idle to ~1200, then back to the screws, one side at a time. I am around 1- 1 1/2 turns out with 27.5 pilots. Didn't get a chance to go out and ride it, later today. We'll see, at least I found something when I took it apart.

Well, that's more like it, lol. I carry a small screwdriver with me so I can do on the road mix screw adjustments. I'll ride until the bike is nice and warmed up, then pull over and tweak the screws a quarter turn or so, then ride another few miles to judge the effect (better or worse?). Then I can pull over again and do some more adjusting if need be.

With a larger pilot jet, the mix screws should dial in like yours have, at about the factory recommended setting or slightly less. So, it seems you're about at the jetting suggestions I made way back at the beginning of all this (one up on the pilots, mains in the low 130s, needles leaned a step). The only big difference I see in your mods compared to mine is the headpipes. You still have the factory double walled ones on there and they are pretty small inside. This can restrict the flow. Eventually, once you put the aftermarket 1.5" headpipes on, you may be able to go up another size on the mains to a 132.5.

With a larger pilot jet, the mix screws should dial in like yours have, at about the factory recommended setting or slightly less. So, it seems you're about at the jetting suggestions I made way back at the beginning of all this (one up on the pilots, mains in the low 130s, needles leaned a step). The only big difference I see in your mods compared to mine is the headpipes. You still have the factory double walled ones on there and they are pretty small inside. This can restrict the flow. Eventually, once you put the aftermarket 1.5" headpipes on, you may be able to go up another size on the mains to a 132.5.

Last edited:

Wilsonsk

XS650 Addict

Yeah, it’s been a journey, I’ll go for a ride after dinner, it was 96 a couple days ago here, 60 today, welcome to Minnesota.

I’ll pick up some tubing and make an oil capsuhelic meter and sync for real, I bought carb boots with spigots when I got new ones.

I’ll pick up some tubing and make an oil capsuhelic meter and sync for real, I bought carb boots with spigots when I got new ones.

Wilsonsk

XS650 Addict

Still not awesome on cold start, fires right up on choke, after 10 seconds or so, starts popping through exhaust on the left side, turning choke off and back on seems to perk up the idle, another 30 seconds or so it will idle off choke. I’m not very bright and forgot all about going through the choke circuit when the carbs were off. It does seem 98% solid when warmed up. I’ll put some miles on at lunchtime and tweak on mixture screws. It amazes me how people are drawn to this thing, someone wants to look at it wherever I go. I live in a smaller town, 3,100 people, everyone watches what everyone else is doing. I think I have the only one of these around here.

I suppose I should pull them and go though the choke circuit, it keeps me up at night.

I suppose I should pull them and go though the choke circuit, it keeps me up at night.

Last edited:

Most of the passageways in the choke are quite large and don't get plugged. However, what often does plug up is the choke feed jet in the float bowl. It's located off to the side near the bottom of the bowl, at the bottom of a pretty deep passageway. Being near the bottom of the bowl like this, if there's any gunk in the bowl, it can get sucked into the jet when you turn the choke on .....

Being located in the bowl means you can clean it without removing the carbs, just take the bowl off. The jet is pressed in place so you can't remove it. You need to blow it clear with compressed air. It's difficult to get the rubber tip on a blowgun to seal around the top of the choke jet passageway because of the air channel that enters it from the side. This is where those needle tips for the blowgun come in handy. You can stick one down into the passageway and rest it right on top of the jet, delivering a good blast of air through it. If the jet is clear, you should be able to see light through it .....

So, if this jet gets plugged, the choke won't work at all. Your chokes seem to be working, but maybe not quite as well as they could or should? Maybe your choke jets are partially plugged and not flowing as much as they should.

Being located in the bowl means you can clean it without removing the carbs, just take the bowl off. The jet is pressed in place so you can't remove it. You need to blow it clear with compressed air. It's difficult to get the rubber tip on a blowgun to seal around the top of the choke jet passageway because of the air channel that enters it from the side. This is where those needle tips for the blowgun come in handy. You can stick one down into the passageway and rest it right on top of the jet, delivering a good blast of air through it. If the jet is clear, you should be able to see light through it .....

So, if this jet gets plugged, the choke won't work at all. Your chokes seem to be working, but maybe not quite as well as they could or should? Maybe your choke jets are partially plugged and not flowing as much as they should.

Just fwiw... and this applies to anything passing liquids or gasses...I have compressed air, where did you get the needle tips?

EDIT: I have some needle tips on order.

What’s the best direction to blow out the passages? Through the mixture screw hole? From the bottom with the bowl off ? From the carb bore back through the ports? All of the above?

I always visualize the direction of flow and make the first blow opposite that direction. The theory being, any blockage is gonna be from the flow side and it'll be easier to dislodge it and force it back out the way it came from. After that I'll make numerous passes with a solvent, followed by air in both directions, but I like the first pass to be against the flow.

If it came in that way, it should blow back out, right?

Wilsonsk

XS650 Addict

I was roaming around the interwebs looking for info on BS38 choke stuff, stumbled on to a youtube video on maintaining the linkage parts of the 76 style choke. I went out and checked and mine was not moving that well, I could easily get them to hang just a little open. I lost my original choke lever because the screw hole stripped. I ordered one from Mike's and it didn't fit quite right, I had to grind a little on the pin as well as bend both the slotted piece on the rod and the lever in the pin area to get them to move together and all of the way both directions. I found that part of it was working ok, but I hadn't lubed that cross shaft, it's clean, but dry. I also realized that the flat detent spring wasn't pushing hard enough to hold it part way open, and didn't help it to close all of the way, If I just "flipped" it off, it would stay a little open. Even though that detent spring has a pin to orient it, I loosened the screw and I could rotate it a little more counter clockwise, I didn't realize how much force that can apply to pushing the lever to the closed position in addition to holding it open. I may rotate it back the other way, tighten it up and bend it, vs. leaving it rotated, the opposing force is going to try to push it back where it was, the pin is designed to stop it, but let's it go too far.

I started it cold, full choke, it ran great for maybe 10 seconds, then started popping, I shut off the choke, it idled fine off choke, I let it idle at least until the valves quieted down and then maybe a minute or two after that. I took off and rode about 25 miles, quite a bit in town, behaved very well at stoplights as well as at 65-70 mph. A bit chilly again today, but a good ride.

I'll drop the bowls and check those passages and do a better service job on my choke linkage. I got all the stuff to put together my syncing capsuhelic tube, maybe I'll get that done this evening.

I started it cold, full choke, it ran great for maybe 10 seconds, then started popping, I shut off the choke, it idled fine off choke, I let it idle at least until the valves quieted down and then maybe a minute or two after that. I took off and rode about 25 miles, quite a bit in town, behaved very well at stoplights as well as at 65-70 mph. A bit chilly again today, but a good ride.

I'll drop the bowls and check those passages and do a better service job on my choke linkage. I got all the stuff to put together my syncing capsuhelic tube, maybe I'll get that done this evening.

Last edited:

Please share the video. I have BS38s to service.

Wilsonsk

XS650 Addict

Here is the one I watched regarding the linkage, it doesn't have much other than that, There are tons of others though. I learned the most from this thread and 5twins. Thank so much for sharing your experience. I search this forum several times a day, I have better luck finding things searching on google vs. the search engine on the forum, not sure why, doesn't matter I get back here either way.Please share the video. I have BS38s to service.

Wilsonsk

XS650 Addict

I went through my choke circuits, they are both open, I couldn't tell for sure if they were blocked or not, but I can spray freely both directions through the choke circuit in the bowl. It seems like the cold start after that was better, it still is cold blooded, stumbling off idle until COMPLETELY warmed up. Not sure if I should go back to the 30 pilot jets or if I should just leave it? I had to order new bowl gaskets, I have exceeded the number of times I can pull the bowls and not tear a gasket, I got it back together but it's hanging by a thread. I also need to go to the 8-32 bowl screws, I've gone to longer screws, but I'm on borrowed time there I think.

10-32... perfect fit.

Curious though, why not just put the M5's in that's supposed to be in there?

Curious though, why not just put the M5's in that's supposed to be in there?

Wilsonsk

XS650 Addict

The threads are stripping out, I’m using longer screws with socket heads where I can, I need to cut a couple for under the choke. A few more disassemblies and they’ll be stripped. I found a thread on here where you make an 8-32 thread chaser and go up to those. 10-32 will work too though. I know they’ll be apart at least one more time in the near future to put my gaskets in and maybe my 30 pilot jets.10-32... perfect fit.

Curious though, why not just put the M5's in that's supposed to be in there?

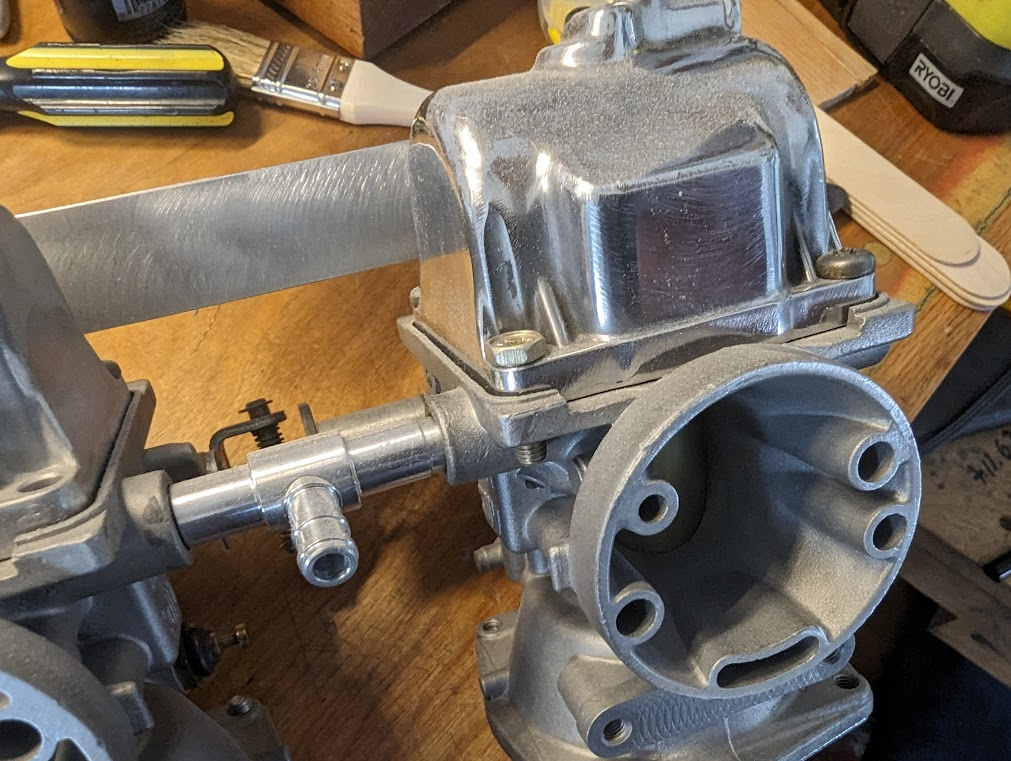

View attachment 251337

It does seem to start better cold now, my choke circuit must have been partially plugged. I just need to get past that stumble until fully warmed up, it didn’t do that when I first got it running.

That's an American 10-32 bolt threaded into the carb in my pic above. It's exactly the same size as the original M5. An 8/32 will just fall through, and since the M5 is close to no longer working, you'll need to go bigger than the 10-32 also...I found a thread on here where you make an 8-32 thread chaser and go up to those. 10-32 will work too though.

Your best bet's gonna be either M5 or 10-32 helicoils.

Similar threads

- Replies

- 9

- Views

- 1K