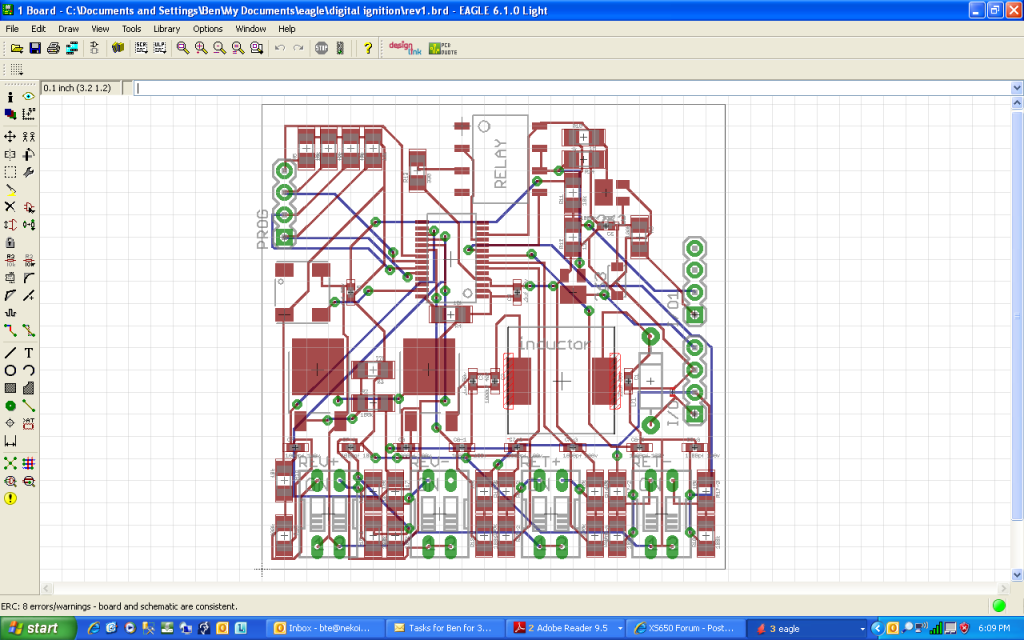

so ive been toying with the idea of making a digital ignition for my xs. as some may have seen, mrriggs has a diagram, parts list, as well as some code for a microcontroller, available for anyone who may want to do such a thing. the last two days ive been putting together a pcb design in my free time and i just finsihed it, the ignition half of it anyway. i still need to lay out the programmer... heres the ignition:

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

mrriggs

XS650 Junkie

Looks cool!

Care to explain how it is different from the standard ignition? Just don't really understand.

http://www.gofastforless.com/ignition/Magic_Box_Install.pdf

The XS comes stock with points and a mechanical advance, which is entirely mechanical. When the littl cam inside the points housing comes around it litterally makes the points contact which in turn causes the ignition to fire. The advance is controlled by the centrafugical force of two weights acting against some springs. While this system certainly works, it requires constant maintenance and you have very little controll over when, how fast and how far it advances...

Then there's an electronic ignition like the pamco. This system does away with the mechanical points. So this system uses electronic components to sense when to fire the coil. Much more dependable, Super easy to use, No constant maintenance. But this system still uses the mechanical advance. So you still have the drawbacks of that part of the stock system.

Finally you have a full digital ignition. This system replaces all mechanical components controlling every aspect of how the ignition behaves. Not only do you get the benefits of not having to set points and needing practically no maintenance but you also get complete controll of all aspects of the advance.

Hopefully you find that helpful...

Then there's an electronic ignition like the pamco. This system does away with the mechanical points. So this system uses electronic components to sense when to fire the coil. Much more dependable, Super easy to use, No constant maintenance. But this system still uses the mechanical advance. So you still have the drawbacks of that part of the stock system.

Finally you have a full digital ignition. This system replaces all mechanical components controlling every aspect of how the ignition behaves. Not only do you get the benefits of not having to set points and needing practically no maintenance but you also get complete controll of all aspects of the advance.

Hopefully you find that helpful...

suiteo

XS650 Enthusiast

Subscribing just to see how this goes. Rhetorical question: Would it be possible to make a digital ignition cam triggered vs. crank triggered if one wanted to run a PMA?

mrriggs

XS650 Junkie

Subscribing just to see how this goes. Rhetorical question: Would it be possible to make a digital ignition cam triggered vs. crank triggered if one wanted to run a PMA?

Yep, just hook it to the points/Pamco, or whatever you got up there, and disable the mechanical advance. The box won't know or care where the signal is coming from as long as it gets one consistent pulse per crank rotation.

suiteo

XS650 Enthusiast

Thanks mrriggs. That's what I figured, but I currently have a TCI, and am trying to think of a way to make something work. I've got no issues with my TCI currently, aside from having to replace the TCI resistor last year. 30 year old electronics have their shelf life, and I'm thinking it would be nice to have a fully digital ignition/advance curve as to not use the points style advance mechanism, and the ability to have a PMA. Time for some more reading.

jeepguy

XS650 Addict

i'm watching this one sounds like a good product

thanks for the interest guys. hopefully when my school semester ends next month ill actually have some time to put towards making this a reality... untill then i guess ill just start sourcing parts, probably end up getting the pcb's made as well.

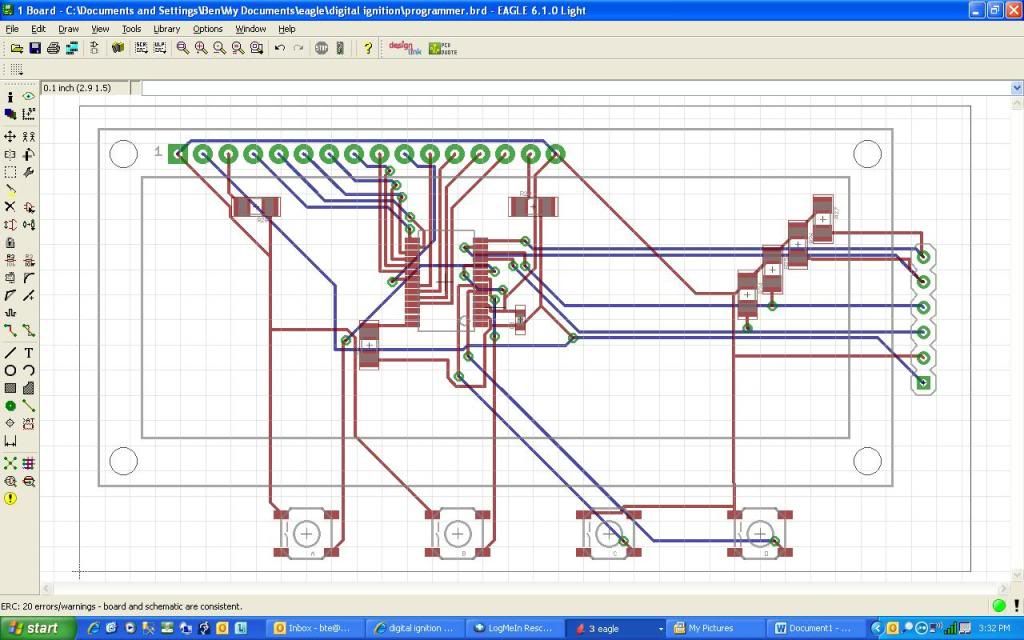

heres the finished programmer

heres the finished programmer

WickedKlown2

XS650 Enthusiast

Has anyone looked into this : Probe Engineering, Inc. http://www.probe-eng.com/servlet/the-Yamaha-XS650/Categories

This is the model I have : http://www.probe-eng.com/servlet/the-6/DX-dsh-65G/Detail

----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

The Model DX-65G is our latest-generation dual-fire ignition system for Yamaha XS650 twins with standard OEM 360-degree crankshafts. It is a lower-cost alternative to single-fire type systems, and may be fitted to all years of the XS650 engine.

The system works with a dual-tower coil; both cylinders fire simultaneously once per crankshaft revolution, with one cylinder firing on its compression stroke, while the other receives a harmless "waste spark" on its exhaust stroke. The system is compatible with 1980-and-later OEM (dual-tower) coils, as well as performance aftermarket coils having a primary resistance between 3 ohms and 5 ohms.

The DX-65G ignition incorporates fully electronic advance-retard, and does away with the unreliable OEM centrifugal-advance mechanism.

Other features of the system include:

- Hall-effect sensor pickups

These non-contact, no-wear magnetic-sensitive devices are resistant to temperature and oil contamination, providing consistent, accurate timing information to the control module.

- Trigger rotor mounts directly to camshaft

The trigger rotor, which carries the flying magnets that trigger the Hall-effect sensors, mounts solidly to the left camshaft end via an internal-expanding collet – there is no long threaded rod through the hollow camshaft to work loose.

- Dedicated “start” sensors for accurate timing down to zero RPM

Dedicated "start" sensors that work from zero RPM to 480 RPM make kick-starting a reliable pleasure, instead of a chore; they also ease the burden on the electric starter, if so equipped.

- Fixed-speed synchronous rev limiter

The built-in rev limiter is set to 7,500 RPM (the original factory redline).

- Built-in static-timing LED

The timing LED lets you accurately set the full-advance timing before you ever fire up the engine.

- Digital tachometer output

The tachometer output connects directly to an electronic tachometer, providing a solid 50% duty-cycle square wave swinging from zero to 12V.

- Auto-timeout

The auto-timeout function continuously checks to see if the engine is spinning; if the bike is not started (or stalls) for 32 seconds after power is switched on, the circuit cuts off the coil current (to protect your battery, your coil, and the control module from overheating damage). Once coil current is cut off, it is automatically reset as soon as the circuit senses crank rotation – you don’t have to reboot the system.

Like all Probe Engineering, Inc. products, the DX-65G carries a two-year limited warranty.

----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Any insight would be appreciated

This is the model I have : http://www.probe-eng.com/servlet/the-6/DX-dsh-65G/Detail

----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

The Model DX-65G is our latest-generation dual-fire ignition system for Yamaha XS650 twins with standard OEM 360-degree crankshafts. It is a lower-cost alternative to single-fire type systems, and may be fitted to all years of the XS650 engine.

The system works with a dual-tower coil; both cylinders fire simultaneously once per crankshaft revolution, with one cylinder firing on its compression stroke, while the other receives a harmless "waste spark" on its exhaust stroke. The system is compatible with 1980-and-later OEM (dual-tower) coils, as well as performance aftermarket coils having a primary resistance between 3 ohms and 5 ohms.

The DX-65G ignition incorporates fully electronic advance-retard, and does away with the unreliable OEM centrifugal-advance mechanism.

Other features of the system include:

- Hall-effect sensor pickups

These non-contact, no-wear magnetic-sensitive devices are resistant to temperature and oil contamination, providing consistent, accurate timing information to the control module.

- Trigger rotor mounts directly to camshaft

The trigger rotor, which carries the flying magnets that trigger the Hall-effect sensors, mounts solidly to the left camshaft end via an internal-expanding collet – there is no long threaded rod through the hollow camshaft to work loose.

- Dedicated “start” sensors for accurate timing down to zero RPM

Dedicated "start" sensors that work from zero RPM to 480 RPM make kick-starting a reliable pleasure, instead of a chore; they also ease the burden on the electric starter, if so equipped.

- Fixed-speed synchronous rev limiter

The built-in rev limiter is set to 7,500 RPM (the original factory redline).

- Built-in static-timing LED

The timing LED lets you accurately set the full-advance timing before you ever fire up the engine.

- Digital tachometer output

The tachometer output connects directly to an electronic tachometer, providing a solid 50% duty-cycle square wave swinging from zero to 12V.

- Auto-timeout

The auto-timeout function continuously checks to see if the engine is spinning; if the bike is not started (or stalls) for 32 seconds after power is switched on, the circuit cuts off the coil current (to protect your battery, your coil, and the control module from overheating damage). Once coil current is cut off, it is automatically reset as soon as the circuit senses crank rotation – you don’t have to reboot the system.

Like all Probe Engineering, Inc. products, the DX-65G carries a two-year limited warranty.

----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Any insight would be appreciated

WickedKlown2

XS650 Enthusiast

You don't need the mechanical advance that you need with a Pamco... I has a nice little control box you make all the settings from...

I was also just seeking advice and to see if it was close to what the OP was trying to do seeing how this has a digital control box...

To each his own I guess and not trying to stir anything up

I was also just seeking advice and to see if it was close to what the OP was trying to do seeing how this has a digital control box...

To each his own I guess and not trying to stir anything up

thats cool dave, basically the same thing im doing.

only difference (besides price!) is that the system im making has a fully configurable advance curve AND a user programmable rev limiter whereas the system you posted only has a programmable rev limiter(and only on the higher end models at that...)

definitely cool though.

only difference (besides price!) is that the system im making has a fully configurable advance curve AND a user programmable rev limiter whereas the system you posted only has a programmable rev limiter(and only on the higher end models at that...)

definitely cool though.

scabber

XS650 Guru

Build it they will come.

arod_1

XS650 Fan

Pretty cool stuff. Although a fully configurable advance curve might be a little much for most people.

It doesn't look like the Probe engineering model takes care of the people that are re-phasing. Is that something that can be easily added?

This looks like something that would appeal to many people. Not just the XS crowd.

It doesn't look like the Probe engineering model takes care of the people that are re-phasing. Is that something that can be easily added?

This looks like something that would appeal to many people. Not just the XS crowd.

scabber

XS650 Guru

Probe makes ignitions for the 277 and 270 rephase

arod_1

XS650 Fan

Yes they do. I should've scrolled a little further down the page. Very expensive!

Not to be the too many cooks in the kitchen, but why are there two boards and why is one called the programmer?

The thing I've envisioned would be a single board and not need to be any bigger than a book of matches. There are little Motorola processors you can get with on board a/d that you could monitor continuously or set up to interrupt when a threshold is crossed. That would be the trigger. You'd need to set up a timer so that the firing transistor is turned off if it's stuck in the on condition for more than a second or two. Re-set by powering up again. You'd need some protection chips on the lines than ran off the board. If you wanted, you could have a usb interface and do things like change curves and thresholds with a pc. That's about all there is to the hardware. The idea must always be stay as hardware un-intensive as possible. Coding-wise you have to make sure it does what you'd want it to when various exceptions like a missed pulse occurs...

The thing I've envisioned would be a single board and not need to be any bigger than a book of matches. There are little Motorola processors you can get with on board a/d that you could monitor continuously or set up to interrupt when a threshold is crossed. That would be the trigger. You'd need to set up a timer so that the firing transistor is turned off if it's stuck in the on condition for more than a second or two. Re-set by powering up again. You'd need some protection chips on the lines than ran off the board. If you wanted, you could have a usb interface and do things like change curves and thresholds with a pc. That's about all there is to the hardware. The idea must always be stay as hardware un-intensive as possible. Coding-wise you have to make sure it does what you'd want it to when various exceptions like a missed pulse occurs...

Similar threads

- Replies

- 14

- Views

- 665