-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

fork spring length

- Thread starter jayel

- Start date

-

- Tags

- suspension

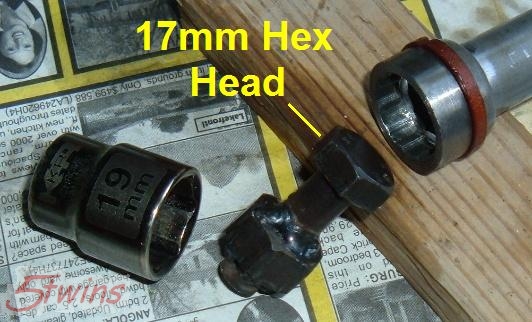

That nylon spacer you found isn't stock, someone must have added it. There shouldn't be anything on top of the damper rod except the spring. Those fork tear-down instructions in the Haynes manual are for an older set of forks. You can't use a pipe with the end squeezed a bit to hold your style damper rod from spinning. The top of your damper rod has what looks like a 12 point socket on it. So, you need a 17mm hex of some sort to insert into that. This could be a large Allen or a 17mm nut or bolt head. I chose the latter and welded a nut to a bolt .....

I use a socket on a bunch of extensions to hold it.

I use a socket on a bunch of extensions to hold it.

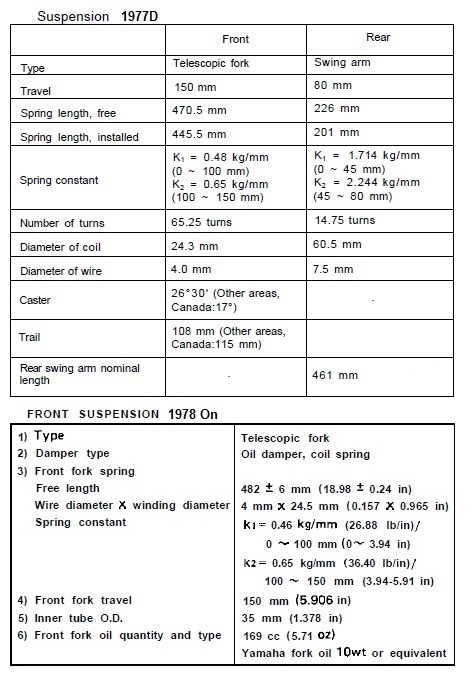

This may be of interest to you, the 35mm fork specs .....

The '77 forks were the 1st year for the 35mm tubes and were a bit different inside. They didn't have the adjustable cap, just a plain plug cap, used slightly shorter springs, and had about a 40mm long preload tube spacer. The top plug cap is actually the same one used on the SR500 forks .....

https://www.partzilla.com/product/y...?ref=59df910615cad55577ac900604c91866d736bbe1

That plain top cap sticks into the fork 22mm. The adjustable cap used on the later models sticks into the fork 33mm at it's lowest setting, 44 and 54mm at it's stiffer settings. As far as how long to make your new spacer goes, yes, that may take some experimenting and will also depend on how long the top cap you end up with is. 70mm may be a bit much, even with a 22mm plain cap. That's 30mm more than the original spacer used with the plain cap. I added an extra inch (25mm) to a later fork with the adjustable caps and it proved to be too much. They were harsh over the little bumps and didn't respond well to them. I shortened them 3/16" and they work nice now.

More oil is really going to help. I've never found it necessary to use anything heavier than the speced 10wt. The '77 forks speced 20wt. but Yamaha changed that to 10wt. for all the later models. I think they made a mistake and found that the 20wt. was just too heavy. Something else you can do to improve the fork action is something called the Minton Mods. This involves drilling out the oil holes in the damper rods, making them slightly bigger, so they flow oil easier and better. This makes the forks much more supple, especially over the little bumps.

The '77 forks were the 1st year for the 35mm tubes and were a bit different inside. They didn't have the adjustable cap, just a plain plug cap, used slightly shorter springs, and had about a 40mm long preload tube spacer. The top plug cap is actually the same one used on the SR500 forks .....

https://www.partzilla.com/product/y...?ref=59df910615cad55577ac900604c91866d736bbe1

That plain top cap sticks into the fork 22mm. The adjustable cap used on the later models sticks into the fork 33mm at it's lowest setting, 44 and 54mm at it's stiffer settings. As far as how long to make your new spacer goes, yes, that may take some experimenting and will also depend on how long the top cap you end up with is. 70mm may be a bit much, even with a 22mm plain cap. That's 30mm more than the original spacer used with the plain cap. I added an extra inch (25mm) to a later fork with the adjustable caps and it proved to be too much. They were harsh over the little bumps and didn't respond well to them. I shortened them 3/16" and they work nice now.

More oil is really going to help. I've never found it necessary to use anything heavier than the speced 10wt. The '77 forks speced 20wt. but Yamaha changed that to 10wt. for all the later models. I think they made a mistake and found that the 20wt. was just too heavy. Something else you can do to improve the fork action is something called the Minton Mods. This involves drilling out the oil holes in the damper rods, making them slightly bigger, so they flow oil easier and better. This makes the forks much more supple, especially over the little bumps.

Hi Oldfart,

unless you really hate the way the air caps look, just don't pump 'em up. The money saved can be better spent elsewhere.

Thanks 5twins,I appreciate your help. Once I got the bush out I used a 17mm bolt and locked two nuts onto it and a couple of extensions as you said. I think I will replace the springs even though they are 482mm which the minimum in my manual and your chart because the air cap, spacer and bush would have compressed the spring about 130mm and they have set?. The springs and cap nuts will take a week to get here so I will drill out the damper rod holes slightly and reassemble with the new parts and oil, 10w as you recommend and no nylon bush and just a 40mm spacer. I was going to assemble without any spacer at first because I thought the p.o must have put it in there but I am glad you mentioned they originally had one. Thanks again for all the info.That nylon spacer you found isn't stock, someone must have added it. There shouldn't be anything on top of the damper rod except the spring. Those fork tear-down instructions in the Haynes manual are for an older set of forks. You can't use a pipe with the end squeezed a bit to hold your style damper rod from spinning. The top of your damper rod has what looks like a 12 point socket on it. So, you need a 17mm hex of some sort to insert into that. This could be a large Allen or a 17mm nut or bolt head. I chose the latter and welded a nut to a bolt .....

I use a socket on a bunch of extensions to hold it.

Well, the '77 forks with the short 22mm plain plug cap had one, the '78 and later forks only had the top cap. If you're getting the short plain caps then yes, you will need a spacer, but the best length may take some experimenting. Here's some info on the Minton Mods, see post #3 .....

http://www.xs650.com/threads/minton-mod-observations.25588/

http://www.xs650.com/threads/minton-mod-observations.25588/

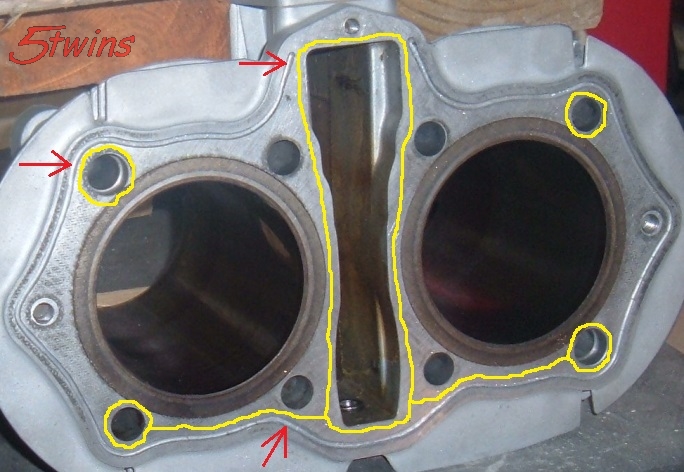

While I was waiting for the fork parts I removed the engine and got exchange head, rocker cover and cylinders with new pistons, rings, gaskets of course and cam chain . When I removed the cylinders I found the cam chain had been installed behind the tensioner arm and the push rod was pushing on the cam chain and had almost completely worn the mushroomed end away?!. Also there is no push rod seat/damper. It is a 60mm thread, six bolt housing with lock nut which i think is a type C by looking at 5twins old post. So the po has left me more mysteries to solve as it is a 1978 special it would not have a type c. At least the tensioner arm is still in as new condition.

Yep, that's a complete type C adjuster assembly, including the housing. The adjuster bolt goes in at a right angle to the housing. On the later type D and E assemblies, the adjuster bolt angles down. This was done to provide clearance for the angle bracket connecting the carbs together. If you have a later set of linked carbs, I'm surprised that type C adjuster assembly fit. You'll want to be looking for a complete type E assembly to replace that.

The engine number matches the frame number so I am not sure why it would have a type c cam chain adjuster housing but I will be upgrading to the E type .Yes it was certainly a tight fit with the bs38 carbs which I could never get to run correctly even after several rebuilds so I replaced them with 34mm mikuni round slide carbs. On another topic I have fitted the new pistons and cylinders and wanted to ask is it a good idea to use any sealant on the head gasket. The company that supplied the parts said to use sealant on the rocker cover but not the head gasket.??

Many of us use copper coat spray gasket sealer on the head gaskets. Before I did that, I used to add a few small narrow beads of sealer in certain areas. These were around the cam chain tunnel, across the front, and around the 4 outside stud holes (because they flow oil) ......

But like I said, I use the spray now, it's much easier.

But like I said, I use the spray now, it's much easier.

Appreciate the advice 5twins. I will be getting a can of permatex copper coat spray today, not cheap though at $40 aus but much easier than applying sealant. Then I can tension down the head and leave it for a day while I rebuild the forks with the new springs and cap nuts, new oil and 20mm pvc spacers. I drilled out the 4 damper rod holes to 1/4 and the small hole straight through to 5/64 as recommended in the minton mods. Looking forward to trying it all.

Great stuff that copper spray gasket sealant, makes the job much easier as long as you put the gasket on the correct way. Three bond on the rocker cover and tensioned down to 30ftlbs, left overnight and re tensioned and fitted engine in frame then when I went to fit the govener and points housings I found the bearings had moved outwards on the cam, so I backed off the head bolts and pushed the bearings in using an f clamp with a socket on each bearing race. Got the engine all together but I had to file the points backing plate slots so I could retard the timing to align the marks. Started easy after kicking over a few times to prime with oil. Runs ok but I've got a timing light on the way, hoping that helps even it out. Didn't want to change too much with the points as it ran fine before the rebuild. I did check the cam marks at tdc but would it run OK one tooth out?. The forks are much better with new springs, minton mods, and 15w fork oil six inches from the top and 20mm spacers under the new cap nuts. Only went for a short ride but it doesn't sag and dive as much, a little harsh over the small bumps, I am looking forward to seeing how it works out on a decent ride when I get the timing sorted.