A few more things to chew on....

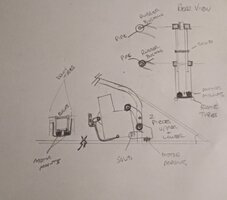

The dogbone's only purpose in life is to stop the engine moving aft under power, so logic would say have it exactly parallel to the top chain run. But if you dig deeper.... the torque is also gonna make the engine (try and) rotate opposite the sprocket. The top of the engine will want to rotate aft and the aft end of the motor will want to rotate down. So, if we angle the dogbone down on it aft side slightly... as a guess 10-15°... with the front pointing up, it will tend to offset the torque rotation. Of course.... that's gonna feed more vibes back into the frame.... so this is a game of tradeoffs.

More chewin'....

Norton made the engine/swingarm combo partially to hold the sprockets in alignment with each other. As we are ponderin'... there's nothing there to do that. You might need another dogbone to offset that. One that mounts horizontally and goes left to right..... to stop the engine from wiggling left and right, moving the sprockets out of alignment. So again... as close to the sprocket as possible.

...and yes, I've done a lot of ponderin' on this over the years.

The dogbone's only purpose in life is to stop the engine moving aft under power, so logic would say have it exactly parallel to the top chain run. But if you dig deeper.... the torque is also gonna make the engine (try and) rotate opposite the sprocket. The top of the engine will want to rotate aft and the aft end of the motor will want to rotate down. So, if we angle the dogbone down on it aft side slightly... as a guess 10-15°... with the front pointing up, it will tend to offset the torque rotation. Of course.... that's gonna feed more vibes back into the frame.... so this is a game of tradeoffs.

More chewin'....

Norton made the engine/swingarm combo partially to hold the sprockets in alignment with each other. As we are ponderin'... there's nothing there to do that. You might need another dogbone to offset that. One that mounts horizontally and goes left to right..... to stop the engine from wiggling left and right, moving the sprockets out of alignment. So again... as close to the sprocket as possible.

...and yes, I've done a lot of ponderin' on this over the years.

Last edited: