I should have started this thread a year ago. But I knew it was going to be a slow build.

Over a year ago I decided to build another bike. I looked around at what I had and found a titled XS2 frame. That's a good start. Since this is going to be a sorta resto-mod not everything is going to be 100% XS2 stuff. Found a 73 front end, added that to the pile. Kept looking and came up with most everything to build a bike.

Started with the frame. Had it sand blasted brought t back home. Decided to do some reinforcing on it. Made some pieces to reinforce it. Welded them in. Then had the frame and swing-arm powder coated.

Cleaned up the front end parts and assembled. Went with chrome headlight and fork ears. You may notice the fork legs are not polished. I decided to do a no polish build. Aluminum pieces will be bead blasted and then Cerakoted. It gives a different type of finish, I like it.

Built a set of wheels. Since it's a resto-mod I got new aluminum rims and stainless spokes.

Next up gauges and controls. Put new face plates in the speedo and tach.

Tires, fenders and a few other things and had a roller.

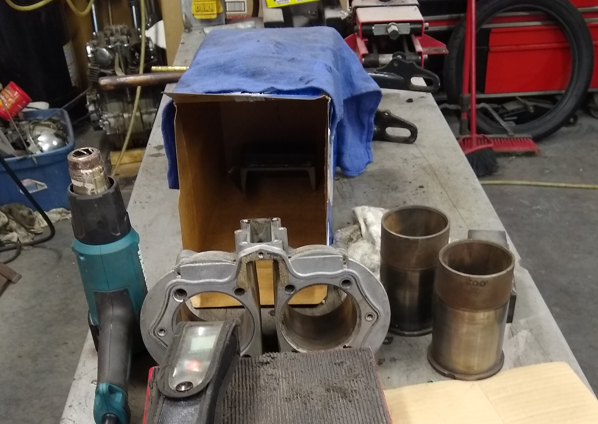

Next thing was engine. Had a 75 engine with around 10k miles on it. Wanted a 750 but with stock jugs. All it took was a heat gun and sleeves came out. Could have had machine shop remove them but I wanted to see how hard they were to get out. Not hard at all.

Sent parts to machine shop to have the 750cc sleeves installed and bored/honed for the pistons, also had the a valve job done on the head. While that was being done cleaned up the engine. Replaced the sump filter and installed a @gggGary 8 plate clutch with new springs plus a few other odds and ends. Got parts back and assembled.

Installed engine. As it sits now. First start tomorrow.

Over a year ago I decided to build another bike. I looked around at what I had and found a titled XS2 frame. That's a good start. Since this is going to be a sorta resto-mod not everything is going to be 100% XS2 stuff. Found a 73 front end, added that to the pile. Kept looking and came up with most everything to build a bike.

Started with the frame. Had it sand blasted brought t back home. Decided to do some reinforcing on it. Made some pieces to reinforce it. Welded them in. Then had the frame and swing-arm powder coated.

Cleaned up the front end parts and assembled. Went with chrome headlight and fork ears. You may notice the fork legs are not polished. I decided to do a no polish build. Aluminum pieces will be bead blasted and then Cerakoted. It gives a different type of finish, I like it.

Built a set of wheels. Since it's a resto-mod I got new aluminum rims and stainless spokes.

Next up gauges and controls. Put new face plates in the speedo and tach.

Tires, fenders and a few other things and had a roller.

Next thing was engine. Had a 75 engine with around 10k miles on it. Wanted a 750 but with stock jugs. All it took was a heat gun and sleeves came out. Could have had machine shop remove them but I wanted to see how hard they were to get out. Not hard at all.

Sent parts to machine shop to have the 750cc sleeves installed and bored/honed for the pistons, also had the a valve job done on the head. While that was being done cleaned up the engine. Replaced the sump filter and installed a @gggGary 8 plate clutch with new springs plus a few other odds and ends. Got parts back and assembled.

Installed engine. As it sits now. First start tomorrow.

Oh well I have spare parts. Engine sounds good. Need to run it through a few more heat cycles and re-torque the head. Then install the head steady, also recheck the valves may have one a little loose. Charging system works. I really like the sound of the exhaust. Not near as loud as I thought it would be. Might be a little louder than the full size commandos on my other XS2.

Oh well I have spare parts. Engine sounds good. Need to run it through a few more heat cycles and re-torque the head. Then install the head steady, also recheck the valves may have one a little loose. Charging system works. I really like the sound of the exhaust. Not near as loud as I thought it would be. Might be a little louder than the full size commandos on my other XS2.