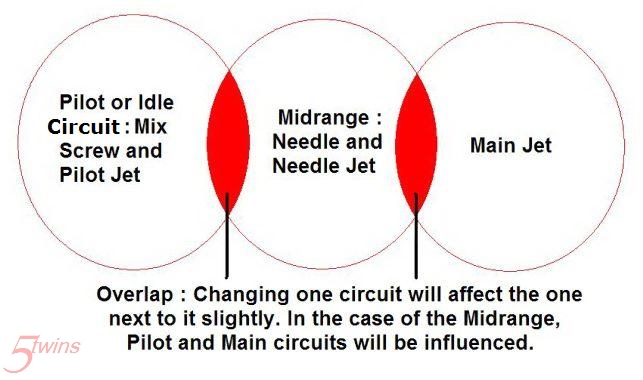

Yes, what you need to understand is that the three circuits in your carb overlap the ones next to them slightly. This means that changing one will affect a portion of the one next to it ......

Yes, two up on the mains will do this, as will one up on the pilots. Pretty much any change will, but whether it's enough to correct the lean midrange, well, only testing will tell you that. I think Gary's needle shim trick is mainly for all stock bikes. Many experience a flat spot just off idle and the shim fixes that. I never needed to do it on my '83 because I didn't have that flat spot. But, I also changed some jets even though it was almost stock. I went up one on the mains because I read even a totally stock BS34 equipped bike runs better that way. I left the stock pilots in but reduced the air jets by two sizes (to a #130). This put some color back on the plugs. They had been very clean, too clean, lol. As I mentioned, the bike was almost stock. I thought it was until I took a closer look and discovered the P.O. had drilled extra holes in the ends of the mufflers. This made the already borderline too lean carbs even leaner and prompted my need to do some jet tinkering. It ran nice with the tweaks.

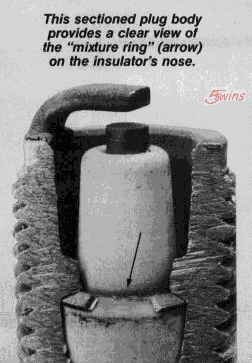

Eventually I did the typical "pipes and pods" mod, and that required more jetting changes. I went up another size on the mains (to 137.5) and did one up on the pilots. With the larger pilot, the two down on the air jets proved to be a bit much, so I went back up one. As I mentioned earlier, the air jet is good for fine tuning and "tuning" the plug color or "smoke ring" .....

I like to get the ring so it covers no more than about the bottom 1/4 of the porcelain. I had that with my jetting when the bike was nearly stock but after the mods, the ring had climbed up to cover about half of the porcelain. Increasing the air jet one size brought it back down to where I like it (about 1/4 coverage). I'm still one size smaller than stock, but with the one size larger pilot, two down on the air jet was just a little too much. I like this about the BS34s, the ability to fine tune the idle circuit and plug color using the air jet. You can't do this on the BS38s, the air jet is pressed in and can't be changed.