I got a set of nylon polishing wheels at Christmas, today was my first time using them but I'm finding even the finest grade leaves very deep scratches in aluminium. I've hit it with wet and dry but I'm going to be going for an eternity and a shopfull of it to get the scratches out, is that quite normal and I just need to knuckle down to it or have I got a set that is missing the finer grade? I'd read on here that they are great for doing rims but these would leave a terrible mess.

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Nylon polishing wheels

- Thread starter Dom

- Start date

I should have said I'm using 400 grit wet and dry, probably should try some 320 first if I had it. I've just tried a final finishing wheel with green compound and can get a really good mirror like shine but the scratches left by the wheel are still evident if looking closely, I think I'd spend a long time getting them out.

I'm certainly not the polishing expert around here, but I'll sometimes start on a bad piece aluminum with 400 carborundum paper, then a sisal wheel with buffing compound, then a cotton wheel with compound. If the nylon wheels are abrading the aluminum worse than 400 grit, they're too aggressive for aluminum. Maybe intended for steel? I do have some very fine (grey) scotchbrite type wheels that I sometimes use at low speed.

Maybe post a pic of what you have....

Maybe post a pic of what you have....

Yes I do wonder if they aren't what they were sold as (Amazon) but they were from a link on here, there's two grades of nylon (red and grey) and a white felt type polishing grade which actually works really well.

Speaking of the DICO wheels?

4" Nyalox Wheel Brushes

4" Gray 80 Grit

4" Orange 120 Grit

4" Blue 240 Grit

4" White Nonabrasive

if so yeah it's a long jump from 240 to shiny.

there are 320 nylon scrubby wheels, from there to black compound on sisal then white on cotton will produce a nice "rider" quality finish.

4" Nyalox Wheel Brushes

4" Gray 80 Grit

4" Orange 120 Grit

4" Blue 240 Grit

4" White Nonabrasive

if so yeah it's a long jump from 240 to shiny.

there are 320 nylon scrubby wheels, from there to black compound on sisal then white on cotton will produce a nice "rider" quality finish.

Attachments

Rustark 18 Pcs Assorted Buffing Wheels,4'' Wool Felt and Nylon Fiber Polishing Wheel Sanding Buffing Disc Abrasive Wheels with Black Emery, Brown Tripoli, General Green Compound for Angle Grinders https://amzn.eu/d/5wvyFzs

That's the ones, they say they fit a 4" grinder, not a UK one they don't! The locking nut on a Makita is too big to fit the recess on the wheel so I whacked a nut and bolt with a washer either side on it then put it in my drill. Not as controllable as a grinder but it worked.

That's the ones, they say they fit a 4" grinder, not a UK one they don't! The locking nut on a Makita is too big to fit the recess on the wheel so I whacked a nut and bolt with a washer either side on it then put it in my drill. Not as controllable as a grinder but it worked.

Those aren't the bristle type wheels so I don't doubt they would scratch the surface easier. The bristle type flex more. Also, by the colors, there may not be any fine grit ones, just medium and coarse.

A little searching probably sez gray is 180 red 240.

you'll want to add least a 320 wheel before jumping to compound.

Like you've experienced just too much of a jump from 240 to compound.

I find a bit of mineral spirits (stoddard solvent) in a spritzer bottle helps in cutting action and removing the black waxy goo left on the aluminum.

you'll want to add least a 320 wheel before jumping to compound.

Like you've experienced just too much of a jump from 240 to compound.

I find a bit of mineral spirits (stoddard solvent) in a spritzer bottle helps in cutting action and removing the black waxy goo left on the aluminum.

Trialing them both the grey is the finer grade, the red was horrendous. I'll try and find a 320 version

From my XS2 build,

What I started with, ( the one I’m holding ).

After knocking corrosion off with blue Dico wheel,

Then wet sanded progressively with 400, 800, and 1500 grit, ready for buffing

And finally buffing, first on a stitched sisal wheel with black rouge, then a finish on a loose flap wheel and white rouge.

What I started with, ( the one I’m holding ).

After knocking corrosion off with blue Dico wheel,

Then wet sanded progressively with 400, 800, and 1500 grit, ready for buffing

And finally buffing, first on a stitched sisal wheel with black rouge, then a finish on a loose flap wheel and white rouge.

Officially hate polishing!! Today I've been and bought some more 320 and 400 wet and dry from Toolstation, rubbed the rear hub down thoroughly then polished through various compounds but I'm just not getting good results. I watched a tutorial on YouTube that suggested you don't need to go further than 400 before getting a mop on it with compound, I think I've decided that's crap, or I need a bigger bench grinder with bigger wheel. I just can get the micro scratches out which look terrible in bright light.

Do you have the coarse black emery compound for your buffing wheel? That should be the 1st compound you use after the 400 paper, and it should remove the paper scratches. You need to use it on a sewn, stiffer wheel, not the loose cotton ones.

I did but I think I need a new and bigger wheel in a more powerful bench grinder, it is my limiting factor I think. I have a really nice grinder but I've been avoiding taking it apart to put polishing wheels on but it may get me the results in after. I find the compound clogs the wheel quite a bit despite me regularly running a wire brush or saw blade over it.Do you have the coarse black emery compound for your buffing wheel? That should be the 1st compound you use after the 400 paper, and it should remove the paper scratches. You need to use it on a sewn, stiffer wheel, not the loose cotton ones.

I think you've hit the key point-

Bigger buffer!

I started small but am up to a horse n a half buffer on a VFD, set speed with dial, spinning 12" wheels for serious work like that backing plate.

spinning 12" wheels for serious work like that backing plate.

Shops that polish for a living typically use 5 to 10HP buffers.

The buffer CANNOT be to big. plus you need buffer not grinder speed.

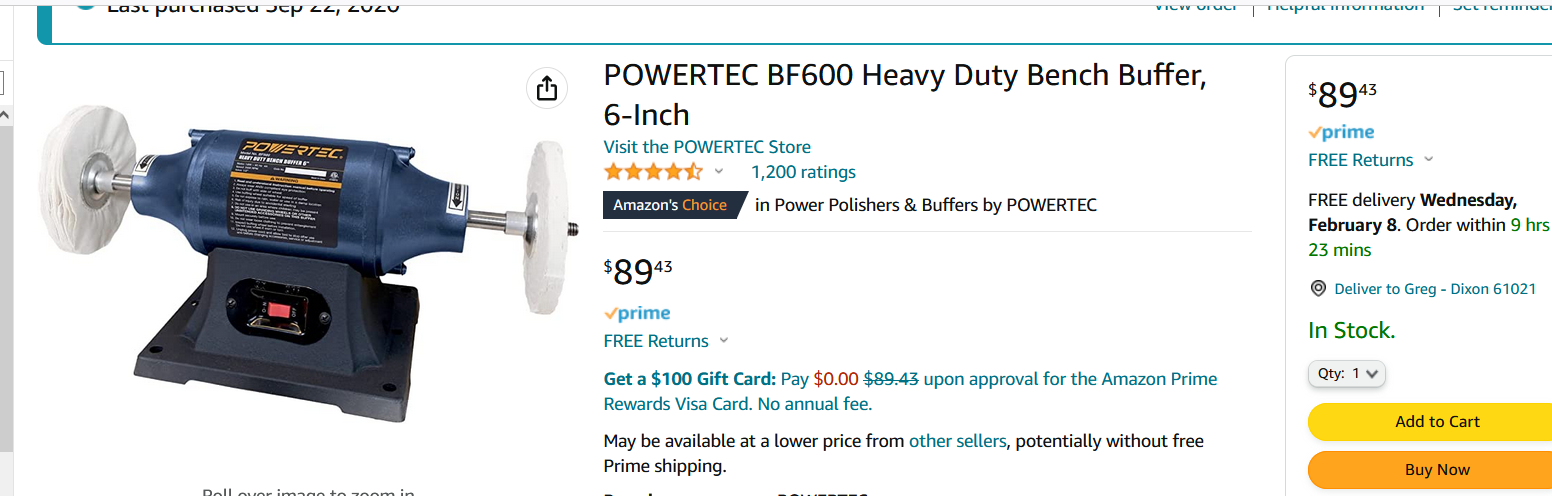

something like this 3/4HP (chinese ponies) will get you by for now and then use. I'd call that one mebby 1/2HP real world.

https://www.harborfreight.com/power...nch-buffers/8-in-stationary-buffer-58827.html

Bigger buffer!

I started small but am up to a horse n a half buffer on a VFD, set speed with dial,

spinning 12" wheels for serious work like that backing plate.

spinning 12" wheels for serious work like that backing plate.Shops that polish for a living typically use 5 to 10HP buffers.

The buffer CANNOT be to big. plus you need buffer not grinder speed.

something like this 3/4HP (chinese ponies) will get you by for now and then use. I'd call that one mebby 1/2HP real world.

https://www.harborfreight.com/power...nch-buffers/8-in-stationary-buffer-58827.html

Last edited:

I bought 1 of these and have been happy with it.

The true measure of a buffer is just how far it can fling whatever little doodad you’re trying to polish!

I like that Bauer stuff. I have several Bauer tools and all have worked well so far. I have a 6" and 8" buffer. The 6" is rather disappointing because you can slow it down if you push the piece against it too hard. So, I use it for the finish buffing with the finer compounds. The 8" is the workhorse. That does the heavy buffing with the black compound. Both are mounted on a special little table I made for them. It's on wheels so is totally portable. Buffing is a dirty job so in the nice weather, I like to take the table outside .....

That's a nice setup, I totally understand doing it outside too, I didn't realise how much mess I'd made until I looked in the mirrorI like that Bauer stuff. I have several Bauer tools and all have worked well so far. I have a 6" and 8" buffer. The 6" is rather disappointing because you can slow it down if you push the piece against it too hard. So, I use it for the finish buffing with the finer compounds. The 8" is the workhorse. That does the heavy buffing with the black compound. Both are mounted on a special little table I made for them. It's on wheels so is totally portable. Buffing is a dirty job so in the nice weather, I like to take the table outside .....

View attachment 235106

The grinder I bought has about a turd of horsepower not made for buffing bogs it right down

But it will sharpen up a lawnmower blade like a damn

But it will sharpen up a lawnmower blade like a damn

Similar threads

- Replies

- 20

- Views

- 2K

- Replies

- 9

- Views

- 913