pamcopete

Ride.Enjoy.Life is Simple

Some time ago I removed the spring loaded pressure bypass from my oil filter because I didn't want un filtered oil to by pass the filter during start up when the pressure is high.

I installed a oil pressure gauge because I wanted to be able to monitor the pressure at start up and keep it below the nominal 15 psi that the bypass valve was supposed to maintain.

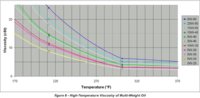

I changed the oil this weekend and refilled with Valevolene 20W-50, as recommended by Yamaha. Upon initial start up, the pressure was well in excess of 15 psi, much more than after previous oil changes, but after a lengthy warm up, the pressure came down as expected, but what this indicated to me was the fact that the viscosity on the bottle of oil can vary. The pressure was so high and lasted so long that I decided to drain the oil and go with Valveoline 10W-40. The results were much better.

So, what can we conclude from this experience? That the bypass valve will allow unfiltered oil to enter the engine upon initial startup and for some time after until the engine warms up sufficiently to reduce the viscosity of the oil. This is most prevalent in cold conditions, so I will probably change back to 20W-50 in March or April.

But for most XS650's with the bypass valve installed, it is very important to warm up the engine before riding because the by pass valve will open and allow unfiltered oil into the engine. Of course, we do have the sump filter, but that is notorious for developing a hole and allowing unfiltered oil into the oil pump and subsequently passed the by pass valve and into the engine. I personally believe that the bypass valve when open increases the flow of oil from the sump, and that is what causes the hole in the sump filter. I removed the by pass valve in my trusty '78/E as well and the sump filter in that engine lasted for 75,000 miles and was intact when I sold the bike.

I installed a oil pressure gauge because I wanted to be able to monitor the pressure at start up and keep it below the nominal 15 psi that the bypass valve was supposed to maintain.

I changed the oil this weekend and refilled with Valevolene 20W-50, as recommended by Yamaha. Upon initial start up, the pressure was well in excess of 15 psi, much more than after previous oil changes, but after a lengthy warm up, the pressure came down as expected, but what this indicated to me was the fact that the viscosity on the bottle of oil can vary. The pressure was so high and lasted so long that I decided to drain the oil and go with Valveoline 10W-40. The results were much better.

So, what can we conclude from this experience? That the bypass valve will allow unfiltered oil to enter the engine upon initial startup and for some time after until the engine warms up sufficiently to reduce the viscosity of the oil. This is most prevalent in cold conditions, so I will probably change back to 20W-50 in March or April.

But for most XS650's with the bypass valve installed, it is very important to warm up the engine before riding because the by pass valve will open and allow unfiltered oil into the engine. Of course, we do have the sump filter, but that is notorious for developing a hole and allowing unfiltered oil into the oil pump and subsequently passed the by pass valve and into the engine. I personally believe that the bypass valve when open increases the flow of oil from the sump, and that is what causes the hole in the sump filter. I removed the by pass valve in my trusty '78/E as well and the sump filter in that engine lasted for 75,000 miles and was intact when I sold the bike.