Hey all been doing research on my right exhaust popping on my 81. So far I've removed the brass plug and adjusted the mixtures out but hadn't fired it up since it was 2am. Anyway I ran across a post stating that the pilot plug was one of the issues. Is this possible? I was just wondering cuz mine falls off with ease. Thanks

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Pilot plug causing issues???

- Thread starter Tia813

- Start date

-

- Tags

- carburetors

You'll need to be a little clearer on exactly what you mean by the pilot plug. If you're referring to the brass plug over the mix screws that you removed then no, it doesn't need to be replaced. If you're referring to the rubber plug over the pilot jet inside the float bowl then yes, it needs to be there. If you're referring to the vacuum cap on the manifold vacuum port then yes, the port needs to be capped or have a vacuum line running off it up to your petcock.

Hi Tia,

dunno about your carbs but the float bowls on my '84 Heritage Special's carbs have little nubbins inside them to hold those rubber plugs in place.

If your carbs are like that those plugs just have to be in tight enough to stay in place until the bowls are back on.

BTW 1) if you just removed the EPA mandated brass plugs atop the idler screws it means that the carbs have never been cleaned properly since new.

I'd say tear 'em down and clean 'em again.

BTW 2) If you get extra rubber plugs they coincidentally fit where the brass EPA plugs were.

Besides being removable at need they are a neater way to keep crud out of there than the alternative dab of grease.

dunno about your carbs but the float bowls on my '84 Heritage Special's carbs have little nubbins inside them to hold those rubber plugs in place.

If your carbs are like that those plugs just have to be in tight enough to stay in place until the bowls are back on.

BTW 1) if you just removed the EPA mandated brass plugs atop the idler screws it means that the carbs have never been cleaned properly since new.

I'd say tear 'em down and clean 'em again.

BTW 2) If you get extra rubber plugs they coincidentally fit where the brass EPA plugs were.

Besides being removable at need they are a neater way to keep crud out of there than the alternative dab of grease.

Last edited:

CDNTX650

XS650 Guru

Is the oring on that mix screw in good shape?

I was just going to order the o-rings but saw that hey had a kit that has a new pilot, washer and spring. I also picked up some mains and pilot jets along with exhaust gaskets since I felt gasses coming out of the head ports. I'll pull the carbs n clean them today. I did take it around the block yesterday after adjusting the mixture screws. Popping seemed better

Stop gap but lightly seat the idle mix screws then back them out to your chosen setting. Yes an exhaust leak at the head can cause popping some v twins are notorious for that issue.

The replacements from Mikes or the ones included in gasket sets are usually quite good. The collar at the head is quite good as well. We might be looking at "user error" here, lol. You did get all of the old seal rings out, right? Sometimes you can't even see them because they're so crusted over and partially burned.

Also, you didn't mention the type of exhaust you have. All stock? Stock headpipes with aftermarket mufflers? Complete aftermarket system? Problems can arise putting aftermarket mufflers on stock headpipes. The headpipes are double walled. There are vent holes down near the muffler and up near the head to let out condensation moisture from in between the pipe layers. If you just saw off the mufflers and clamp the new ones to the outer headpipe, exhaust gases can travel up between the pipe layers and sputter out the vent holes. It may appear that the headpipe to engine connection is leaking when it may in fact not be that at all.

Also, you didn't mention the type of exhaust you have. All stock? Stock headpipes with aftermarket mufflers? Complete aftermarket system? Problems can arise putting aftermarket mufflers on stock headpipes. The headpipes are double walled. There are vent holes down near the muffler and up near the head to let out condensation moisture from in between the pipe layers. If you just saw off the mufflers and clamp the new ones to the outer headpipe, exhaust gases can travel up between the pipe layers and sputter out the vent holes. It may appear that the headpipe to engine connection is leaking when it may in fact not be that at all.

I wouldn't doubt operator error at this point lol. I am using the stock head pipe, wrapped in header tape. Pipes are extended to mid part of the wheel by using car exhaust. No mufflers are used at this point although I'm going to order HHB baffles. I do remember the holes near the head. I may attempt to plug them up. All else fails I'll fork over new ones.

I did take it out on the road yesterday. Popping did go down but for sure jetting is needed. When I got back I pulled both plugs and saw that right side was black m sooty while the left side was clean with a little white. That would indicate a lean condition. I have a lot of carb work a head of me lol. I hope that's it just carbs

I did take it out on the road yesterday. Popping did go down but for sure jetting is needed. When I got back I pulled both plugs and saw that right side was black m sooty while the left side was clean with a little white. That would indicate a lean condition. I have a lot of carb work a head of me lol. I hope that's it just carbs

In order to prevent exhaust sputtering out the breather holes in the stock headpipes when you attach aftermarket mufflers or pipe extensions, you have to connect them to the inner pipe, not the outer one. Here's a thread that details the way to do it. Roll down to post #19 .....

http://www.xs650.com/forum/showthread.php?t=276&highlight=pamcopete+exhaust+adapter

http://www.xs650.com/forum/showthread.php?t=276&highlight=pamcopete+exhaust+adapter

Just an update--- while I waited for my mains, pilot jets and idle mixture screw kit to come in I redid my exhaust, cleaned, bench sync and adjusted the floats to 22mm per one of the vids posted. Once I received my parts I threw on the 137.5 main and 45 pilot jet. Threw on the new mixture screw kit and backed them out 3 turns. Once started the right exhaust has a nice constant thump but NOW the left exhaust is weak..... I attempted to adjust the mixture screws but don't have the ear for it. I took it out around the block anyway. No power down low but once she got goin she was good. I'm going to attempt to adjust the mixture tomorrow.

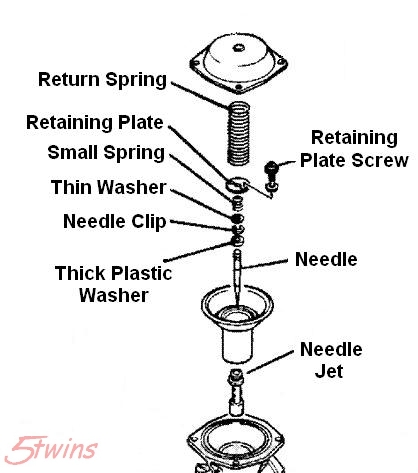

Both plugs look rich but the left obviously is more so. I would try a 135 main, the 137.5 may be a bit much. Have you inspected the needle assembly in the slide? I ask because if done wrong, the needle can sit too high and that would cause rich running. Here's the assembly sequence. The little spring goes on top of the needle and its assorted spacer washers. If it was put under them, the needle would sit too high .....

Yes, tuning the BS34 mix screws by ear can be difficult because they are so E.P.A. strangled. Adjusting the screws in and out doesn't seem to have much of an effect, or at least a major one. I use small quick throttle blips and listen for popping and note how quickly the RPMs drop back down. Popping and hanging idle speed are lean indicators. I turn both mix screws in until I get these symptoms (usually down to around 2 turns out) then work both back out in unison by 1/4 turns until they go away. That's usually somewhere in the 3 to 3.5 turns out range.

Yes, tuning the BS34 mix screws by ear can be difficult because they are so E.P.A. strangled. Adjusting the screws in and out doesn't seem to have much of an effect, or at least a major one. I use small quick throttle blips and listen for popping and note how quickly the RPMs drop back down. Popping and hanging idle speed are lean indicators. I turn both mix screws in until I get these symptoms (usually down to around 2 turns out) then work both back out in unison by 1/4 turns until they go away. That's usually somewhere in the 3 to 3.5 turns out range.

chizler62

XS650 Addict

You can do an idle drop by ear.

Lightly turn screws in till they softly bottom. Then back out to suggested starting point. I think on those I use 2-1/4 turns out.

Fire bike up and bring to operating temperature. Set idle exactly where you'd like it. I use a separate tach off the plug wire.

Once warm, idling steady and consistent. Turn left mixture screw in 1/4 turn. Wait several seconds and see if the idle drops. No, then try another 1/4 turn and wait. Do this until the idle drops down a noticeable amount. Once idle drops, back fuel screw out 1/2 turn. If you turn the fuel screw completely in and the idle doesn't drop then your pilots are too big.

Reset idle to same place you started with and repeat for right carb.

If you don't properly do this and have the wrong pilot in...it'll affect the entire system, both needles and mains.

The only way to get it closer is with an EGA machine and that'd be within a 1/4 turn.

Posted via Mobile

Lightly turn screws in till they softly bottom. Then back out to suggested starting point. I think on those I use 2-1/4 turns out.

Fire bike up and bring to operating temperature. Set idle exactly where you'd like it. I use a separate tach off the plug wire.

Once warm, idling steady and consistent. Turn left mixture screw in 1/4 turn. Wait several seconds and see if the idle drops. No, then try another 1/4 turn and wait. Do this until the idle drops down a noticeable amount. Once idle drops, back fuel screw out 1/2 turn. If you turn the fuel screw completely in and the idle doesn't drop then your pilots are too big.

Reset idle to same place you started with and repeat for right carb.

If you don't properly do this and have the wrong pilot in...it'll affect the entire system, both needles and mains.

The only way to get it closer is with an EGA machine and that'd be within a 1/4 turn.

Posted via Mobile

Thanks guys for the replies. This is the first time in 3yrs since she's started and possibly 5yrs since I've done a valve adjustment. Probably doesn't need it but who knows I may have done it incorrectly. For piece of mind I'm going to check the chain tension, valve lash, timing then the carbs. I will apply both methods for the mix screws. My problem was I wasn't waiting for the idle to go down. I was turning and expecting a change right away.. I'll also check the needle assy.. When I do get to the carbs I'm going to change one thing at a time instead of throwing everything in. I'll keep you posted. Thanks again

Ok so checked cam chain which was good, left valves dead on, right side needed adjustment and timing was good. Removed the #45 pilot and went back to the 42, checked the slide assy like 5twins suggested and they were put together correctly but needed cleaning because old gas was built up.

Went to adjust the mixture screw and the only time I got it to start bogging was close to an 1/8 of a turn to fully closed... Is that normal? I failed I mention that I am using mikes pod filters, which I've learned are no good and tc bros aluminum carb holders. Thanks again

Went to adjust the mixture screw and the only time I got it to start bogging was close to an 1/8 of a turn to fully closed... Is that normal? I failed I mention that I am using mikes pod filters, which I've learned are no good and tc bros aluminum carb holders. Thanks again

chizler62

XS650 Addict

If your idle is in the right place, staying consistent, not hovering and you've turned the mixture screws in slowly 1/4 turn at a time(one side at a time) and the only time the idle either went up or down was 1/8 from fully seated than your pilots are too big. Try the next size down.

The pilot circuit will effect the entire throttle range slightly. So its important to get that set before moving needles and changing main etc.

The pilot circuit will effect the entire throttle range slightly. So its important to get that set before moving needles and changing main etc.

Figured out I'm concentrating too up on the turns since it's such a pain to get my screw driver into the hole. So I soldered an old mixture screw on top of the other so it's easier. Well it worked I was able to concentrate more on the rpm change and got it right. It's very subtle but ended up 3 outish. Took her for a spin no flat spots or bogging. Still running fat but at this point I'm just glad this mixture thing is out of the way. I did order smaller pilots(ordered after the fact) and new float parts. Gonna throw on the #40s just for grins. From there I'll drop the 135 mains n see if I can leaner out a bit. Thanks again for everyone's input.

Attachments

Similar threads

- Replies

- 61

- Views

- 4K