Pitting in Bearings

I have recently Done spring service on Bicycles. Lubing chains and some minor stuff. For ladies

Checking the gear shifting and some paint. Keeping the rust away

While at it I started to rebuild rear hubs and Wheels -- Getting bypassed by the youngster so it says Swish .Trying more gears.

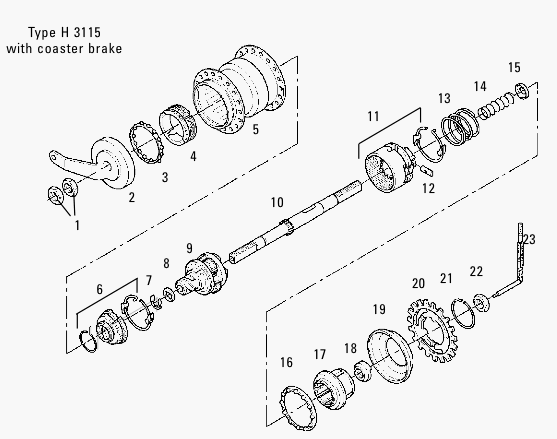

Sachs Torpedo 3 gear internal Planet gear

The issue -- one hub has a worn bearing # 16 and on the race there is a very very very very minor pitting on one spot # 17

The bearing I can buy .but the race can be more difficult .. The same problem happens on Motorcycle bearings also.

Up til now I have always replaced .But it might not always be possible if it is very old machines no parts.Available

Have anyone any experience on this .Is it a no starter putting in new balls in a slightly pitted race. even though very very very very minor pitting

it is there.

Anyone done that ??

I have recently Done spring service on Bicycles. Lubing chains and some minor stuff. For ladies

Checking the gear shifting and some paint. Keeping the rust away

While at it I started to rebuild rear hubs and Wheels -- Getting bypassed by the youngster so it says Swish .Trying more gears.

Sachs Torpedo 3 gear internal Planet gear

The issue -- one hub has a worn bearing # 16 and on the race there is a very very very very minor pitting on one spot # 17

The bearing I can buy .but the race can be more difficult .. The same problem happens on Motorcycle bearings also.

Up til now I have always replaced .But it might not always be possible if it is very old machines no parts.Available

Have anyone any experience on this .Is it a no starter putting in new balls in a slightly pitted race. even though very very very very minor pitting

it is there.

Anyone done that ??