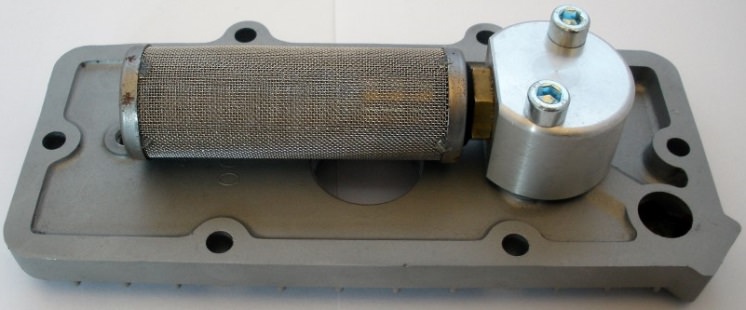

We're all aware of the sump filter issues, specifically the torn screening at the end where the oil intake port is. Apparently the suction right at that port is too much for the screening around it to handle. Many of us simply patch the tear in the screen with JB Weld. That's been working well for me but recently when I pulled one of these patched filters, I found it had torn again opposite the patch, on the backside. So, it seems patching the normal blow-out point simply moves the stress point somewhere else on that end of the filter. Heiden sells an aftermarket designed filter that seems to address that. While it still has screening, they don't put it around the oil intake port but rather space it away from it about an inch or so .....

And if you look closely, it seems they may have also louvered or baffled the intake pipe inside the screening, maybe as a further step to reduce the force of the suction.

So I was thinking, maybe a tin shield or guard of some sort around the vulnerable end of the stock filter might be of some benefit. I don't think it would need to block off the oil flow 100%, just lessen it so the screening doesn't take such a beating. So, I had at it with some sheet metal angle, tin snips, and a drill. A little finish filing and tap-tap fitting with a small ball pein was also done.

I started out by making card stock templates which then got traced onto the sheet metal. I originally thought I would need two separate shields, one for each side but while laying out the first one, I decided to string the two sides together and attempt to just wrap it around the end of the filter. It worked pretty good .....

You probably noticed the numerous templates in the pic above. I discovered that the magnet position on the backside of the filters varies, sometimes by just a little but sometimes by a lot. The aftermarket filter also differs from any of the stock ones. So, several different length templates for the backside were required. The front side template is a "one size fits all", lol.

Testing will begin with my next oil change and I'll let you know if this does any good or not.

And if you look closely, it seems they may have also louvered or baffled the intake pipe inside the screening, maybe as a further step to reduce the force of the suction.

So I was thinking, maybe a tin shield or guard of some sort around the vulnerable end of the stock filter might be of some benefit. I don't think it would need to block off the oil flow 100%, just lessen it so the screening doesn't take such a beating. So, I had at it with some sheet metal angle, tin snips, and a drill. A little finish filing and tap-tap fitting with a small ball pein was also done.

I started out by making card stock templates which then got traced onto the sheet metal. I originally thought I would need two separate shields, one for each side but while laying out the first one, I decided to string the two sides together and attempt to just wrap it around the end of the filter. It worked pretty good .....

You probably noticed the numerous templates in the pic above. I discovered that the magnet position on the backside of the filters varies, sometimes by just a little but sometimes by a lot. The aftermarket filter also differs from any of the stock ones. So, several different length templates for the backside were required. The front side template is a "one size fits all", lol.

Testing will begin with my next oil change and I'll let you know if this does any good or not.