-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

TCI Replacement 2020 It Works

- Thread starter Team Junk

- Start date

Think I'm going grind off a little off the wings to allow the pickup to move up a little so it will clear the the cover.

The 3/8 nut on the allthread grips the id of the cam pretty well.

Next is getting the pickup fastened to something so I can see if it makes spark at kick start speed.

Got to take a nap first.

The 3/8 nut on the allthread grips the id of the cam pretty well.

Next is getting the pickup fastened to something so I can see if it makes spark at kick start speed.

Got to take a nap first.

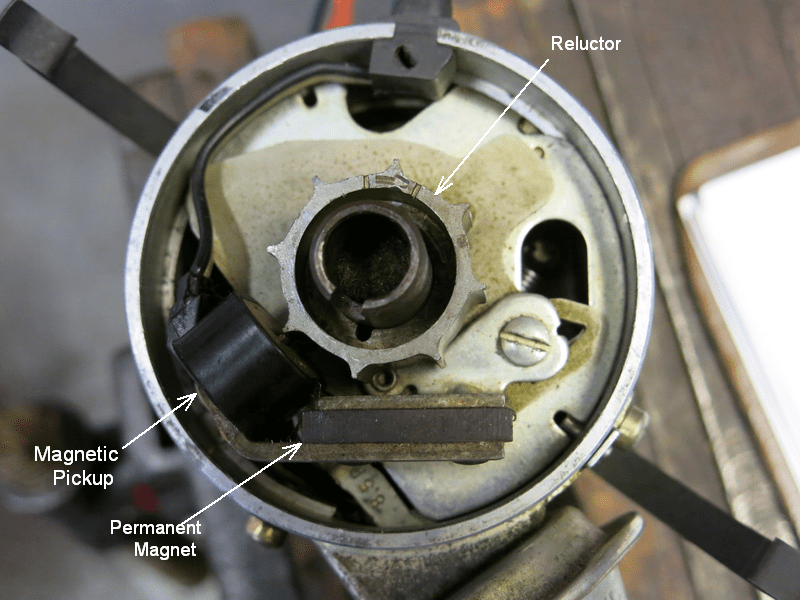

I did watch the video from Chrysler # 1452 and the shape of the reluctor Tooth can be important

15:33 ish wants sharp edges and the gap settings Perhaps you checked this already on the oscilloscope

15:33 ish wants sharp edges and the gap settings Perhaps you checked this already on the oscilloscope

Was hoping to get away with a unmolested wingnut.I did watch the video from Chrysler # 1452 and the shape of the reluctor Tooth can be important

Close, it sparks when I spin the allthread thru the cam but no joy kicking it even with the plugs out.

I have been trying to keep the amount of fabrication, fuzzing around to a minimum.

Jan_p was spot on about the difference in shape and profile.

It looks like the the wingnut will have to face the grinder. Or some other fate ????

The good news is the pickup alines with a coupe of holes in the yamaha points plate.

Last edited:

Just for input .Thinking out loud.It would be possible to bend or weld an U shaped profile and perhaps have an adjustment

possibility having the pointed shape for the reluctor and being able to use shims or so get the right distance

possibility having the pointed shape for the reluctor and being able to use shims or so get the right distance

I share an image of an adaptation of a group of xs650s from Mexico. I think a little modification to the wing nut might work.Just for input .Thinking out loud.It would be possible to bend or weld an U shaped profile and perhaps have an adjustment

possibility having the pointed shape for the reluctor and being able to use shims or so get the right distance

Do you know what sensor (trigger) that is?I share an image of an adaptation of a group of xs650s from Mexico. I think a little modification to the wing nut might work.

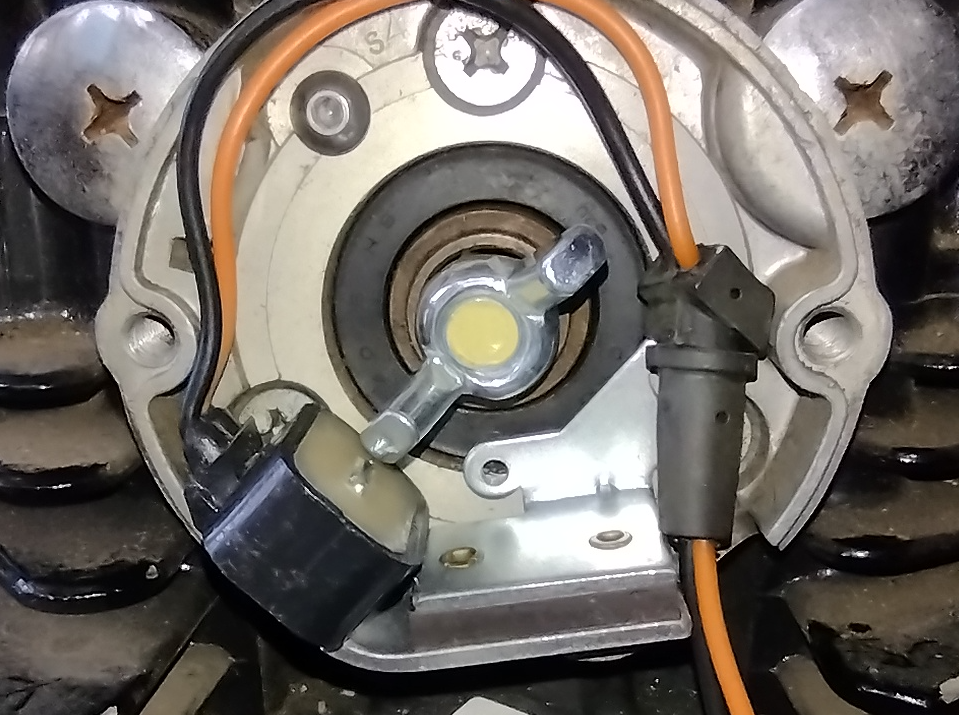

View attachment 260974

¿Sabes qué sensor (disparador) es ese?

Its been a long time

Doesn't know nothing.

Looks like there's two magnet pieces inserted to the camshaft end? Different set up to your wing nut?Do you know what sensor (trigger) that is?

¿Sabes qué sensor (disparador) es ese?

It does not indicate which motorcycle or vehicle it belongs to. I think it is an SR250 pickup.

Do you know what sensor (trigger) that is?

¿Sabes qué sensor (disparador) es ese?

Last edited:

Its been a long time

Doesn't know nothing.

Ah, I see. Looked like magnets to me. Thanks for posting.They are just two pieces of metal welded together. Personally I wouldn't want to mess up the cam without a replacement, it's easier to get those wing nuts and modify them.

View attachment 260977

Do you know if the ignition works with that pick up? Is it Yamaha TCI, or something else?

As far as I remember, the person adapted a Chinese CDI from a work motorcycle. Cdi without advance and the original advance mechanism is used.Ah, I see. Looked like magnets to me. Thanks for posting.

Do you know if the ignition works with that pick up? Is it Yamaha TCI, or something else?

Its been a long time

Doesn't know nothing.

Thank you. That's very interesting to hear.As far as I remember, the person adapted a Chinese CDI from a work motorcycle. Cdi without advance and the original advance mechanism is used.

My thought exactly. .89c wingnut vs who knows what for a repop points cam.They are just two pieces of metal welded together. Personally I wouldn't want to mess up the cam without a replacement, it's easier to get those wing nuts and modify them.

What I'm curious about is where did the washer for a backing come from. Washers that size a hard to come by

. There again don't want to add holes to original points plate.

The wingnut is going to work. The factory gap for the reluctor is .008 inch. I'm not running it nearly that close more like .8 of a inch. I working on tightening that up.

Right now I have a old design reluctor with magnets installed right now.

Have spent the day prepping for a squall line that's coming through so not so much Gonzo.

The design goal here is something that someone can reproduce with not much more than an electric drill.

Worst case I will drill holes in the wings and mount small magnets to boost the signal.

Wasted spark. Ether a TCI style dual outlet coil or the points coils in parallel. I prefer the the Honda cb750 style dual output coil myself.

One thing I like about this mod using the Mopar pickup is that the Mopar electronic ignition first appeared on a 1973 340 hotrod engine setup so it is a contemporary to the 650. This setup could of been done back when the 650s were new.

If you use the stock points wiring for the pickups and the stock coils the whole mod is pretty stock looking from the outside.

One thing I like about this mod using the Mopar pickup is that the Mopar electronic ignition first appeared on a 1973 340 hotrod engine setup so it is a contemporary to the 650. This setup could of been done back when the 650s were new.

If you use the stock points wiring for the pickups and the stock coils the whole mod is pretty stock looking from the outside.

Last edited:

Haven't had much of a chance to work on the Gonzo. Made a 500 mile trip to Houston and back on Saturday and Sunday. Wow things have changed out there on the super slab.

Yesterday I rigged up the Mopar pickup and v8 reluctor to a GM HEI.

Result "Sparkulation.

The gap is closer to .125 than .008 factory spec but it makes sparks

I really like the HEI module. Pretty small and straight forward to use. This setup require the stock advance unit and attaching the mopar reluctor is a challenge on the stock advance rod.

Stock mopar distributer setup. The reluctor is roughly 1 inch in diameter . One of the smallest I've found.

Next phase modded 2 lobe mopar reluctor and Gonzo.

And the wingnut will meet the grinder.

Yesterday I rigged up the Mopar pickup and v8 reluctor to a GM HEI.

Result "Sparkulation.

The gap is closer to .125 than .008 factory spec but it makes sparks

I really like the HEI module. Pretty small and straight forward to use. This setup require the stock advance unit and attaching the mopar reluctor is a challenge on the stock advance rod.

Stock mopar distributer setup. The reluctor is roughly 1 inch in diameter . One of the smallest I've found.

Next phase modded 2 lobe mopar reluctor and Gonzo.

And the wingnut will meet the grinder.

I'm pretty sure the advance is set by the frequency of the pulses and not the width.Since the advance relies on the leading and trailing edge of the trigger to determine advance (that's my theory anyway), you could always vary the thickness of the wingnut to reduce it if it's too much.

Hope to confirm this soon. Next step after getting this thing secured to the bike is put some gas in and see what it does.

AUTOMAN

XS650 Addict

No advance with the HEI as is.