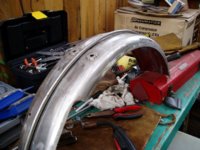

Hello, I finally worked on my project 80 chopper some more this weekend. Am attaching a few pics. I'm using a 5 in trailer fender de-radiused so it kind of matches a 16 in wheel. I bent a piece of 3/8 steel tube to match the curve and tacked in on on the center top of the fender, figuring it would look good, and most importantly, shelter my taillight wires.

I don't like the idea of exposed wires underneath a fender that sits that close to the tire.

so........

I tacked it in place after spending I'd say a couple hours messing with it getting it bent to match curve of fender.

Then I thought, well just leave it tacked and take to a pro welder who can TIG weld the rest with some pretty welds.

But no.

I couldn't leave it alone, and went ahead and welded the entire length of it on both sides.

Finally, on the 2nd side I found a position that yielded a nice bead, which though small and neat, DID join the metal. I did it by actually dragging the copper tip of the gun TOUCHING the steel tube, that gave me a nice guide and the wire melted nice right where I wanted. Wish I had been able to do the whole thing that way. Only prob, the other side is big blobby inconsistent welds.

Great penetration and all that, just ugly as sin. Some of it I will grind down.

(hey at least I didn't blow holes through it like I did with my pipes)

Thinking of using epoxy resin mixed with copper dust to fill in any tiny "caverns" that remain. I used that combo once to repair the handle of a pocket knife, and it worked great (strong as hell), and the copper dust (which we generate here at my work) gave it a really neat look. Would use JB weld, but it's too ugly. Altho, I'm gonna paint it...so maybe I'll use the JB.

here are a couple pics.

Next I gotta figure out about the taillight. Drill a hole in the rear part of the base for the tubing to poke into.

Another thing I don't understand about the tailight - it has only 2 wires coming off it. I wonder if that means it "grounds" through the bolts which attach it to frame?

anyway, thx for looking.

I don't like the idea of exposed wires underneath a fender that sits that close to the tire.

so........

I tacked it in place after spending I'd say a couple hours messing with it getting it bent to match curve of fender.

Then I thought, well just leave it tacked and take to a pro welder who can TIG weld the rest with some pretty welds.

But no.

I couldn't leave it alone, and went ahead and welded the entire length of it on both sides.

Finally, on the 2nd side I found a position that yielded a nice bead, which though small and neat, DID join the metal. I did it by actually dragging the copper tip of the gun TOUCHING the steel tube, that gave me a nice guide and the wire melted nice right where I wanted. Wish I had been able to do the whole thing that way. Only prob, the other side is big blobby inconsistent welds.

Great penetration and all that, just ugly as sin. Some of it I will grind down.

(hey at least I didn't blow holes through it like I did with my pipes)

Thinking of using epoxy resin mixed with copper dust to fill in any tiny "caverns" that remain. I used that combo once to repair the handle of a pocket knife, and it worked great (strong as hell), and the copper dust (which we generate here at my work) gave it a really neat look. Would use JB weld, but it's too ugly. Altho, I'm gonna paint it...so maybe I'll use the JB.

here are a couple pics.

Next I gotta figure out about the taillight. Drill a hole in the rear part of the base for the tubing to poke into.

Another thing I don't understand about the tailight - it has only 2 wires coming off it. I wonder if that means it "grounds" through the bolts which attach it to frame?

anyway, thx for looking.