I am resurrecting a very neglected 1978 XS650. Gave a complete tune-up including valve adjustment, started it up, warmed it up on the road, and I had a loud ticking. Used a stethoscope to narrow it down to the LEFT INTAKE VALVE lash too big. The bike was already hot, so I set the gap really small and the noise went away. I did some more road testing, and I tightened the cam chain again, this time hot, enough to necessitate setting all of the valves again, which I did cold, of course. I noticed that the tip of the LEFT INTAKE VALVE adjuster looked hammered, like it had been too tight, so I put a new adjuster in.

Next day, more road testing, and all of a sudden I get a really loud ticking again. Didn't have the stethoscope with me, but I'm sure it was the LEFT INTAKE VALVE lash. Then a few miles later, it goes away again.

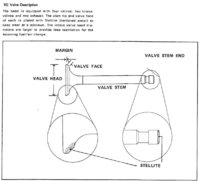

Anyone ever run into this? Valve lash on a single valve spontaneously goes in and out of adjustment? I always carefully feel for slop when I adjust valve lash, and it was normal. Otherwise, I would say gummy or sloppy rocker arm and shaft, but I don't feel abnormal slop. Could it be a gummy or sticking valve and valve guide? Try putting Sea Foam in the crankcase? Any ideas?

Next day, more road testing, and all of a sudden I get a really loud ticking again. Didn't have the stethoscope with me, but I'm sure it was the LEFT INTAKE VALVE lash. Then a few miles later, it goes away again.

Anyone ever run into this? Valve lash on a single valve spontaneously goes in and out of adjustment? I always carefully feel for slop when I adjust valve lash, and it was normal. Otherwise, I would say gummy or sloppy rocker arm and shaft, but I don't feel abnormal slop. Could it be a gummy or sticking valve and valve guide? Try putting Sea Foam in the crankcase? Any ideas?

for a few years now, it works better than Kearney's rust cutter, and just about anything else I've tried.

for a few years now, it works better than Kearney's rust cutter, and just about anything else I've tried.

. When valve rotates (slightly) in guide and spring/retainer, it could possibly be increasing or decreasing clearance.

. When valve rotates (slightly) in guide and spring/retainer, it could possibly be increasing or decreasing clearance.