luckynumber0

In Over His Head

It's an '82 I bought a year ago and have put about 2k miles on. Odo was frozen at 34,000 miles when I got it. It's my first 650 and my second bike ever...I had picked it up for almost nothing because it was all in boxes out in Modesto, CA - a father-son project they abandoned when they didn't find any points under the covers  I switched out the old TCI for one off ebay, cleaned out the carbs, and it started right up. Been fixing/upgrading things here and there since.

I switched out the old TCI for one off ebay, cleaned out the carbs, and it started right up. Been fixing/upgrading things here and there since.

Just a month ago, I was riding to work when I heard a brand new sound from the top end. Turned around home and listened up with a stethoscope and it sounded like the cam chain guide had rubbed through to the metal. After some colorful language, I resigned to pull the engine and give it as good a goin' through as I can.

I'm going by the original '82 factory manual (the one with it's own yamaha part number) and searching through here when I get stuck. I'm taking my time with all of this because I've broken things through impatience before. Here we go:

Complete:

Stripping down:

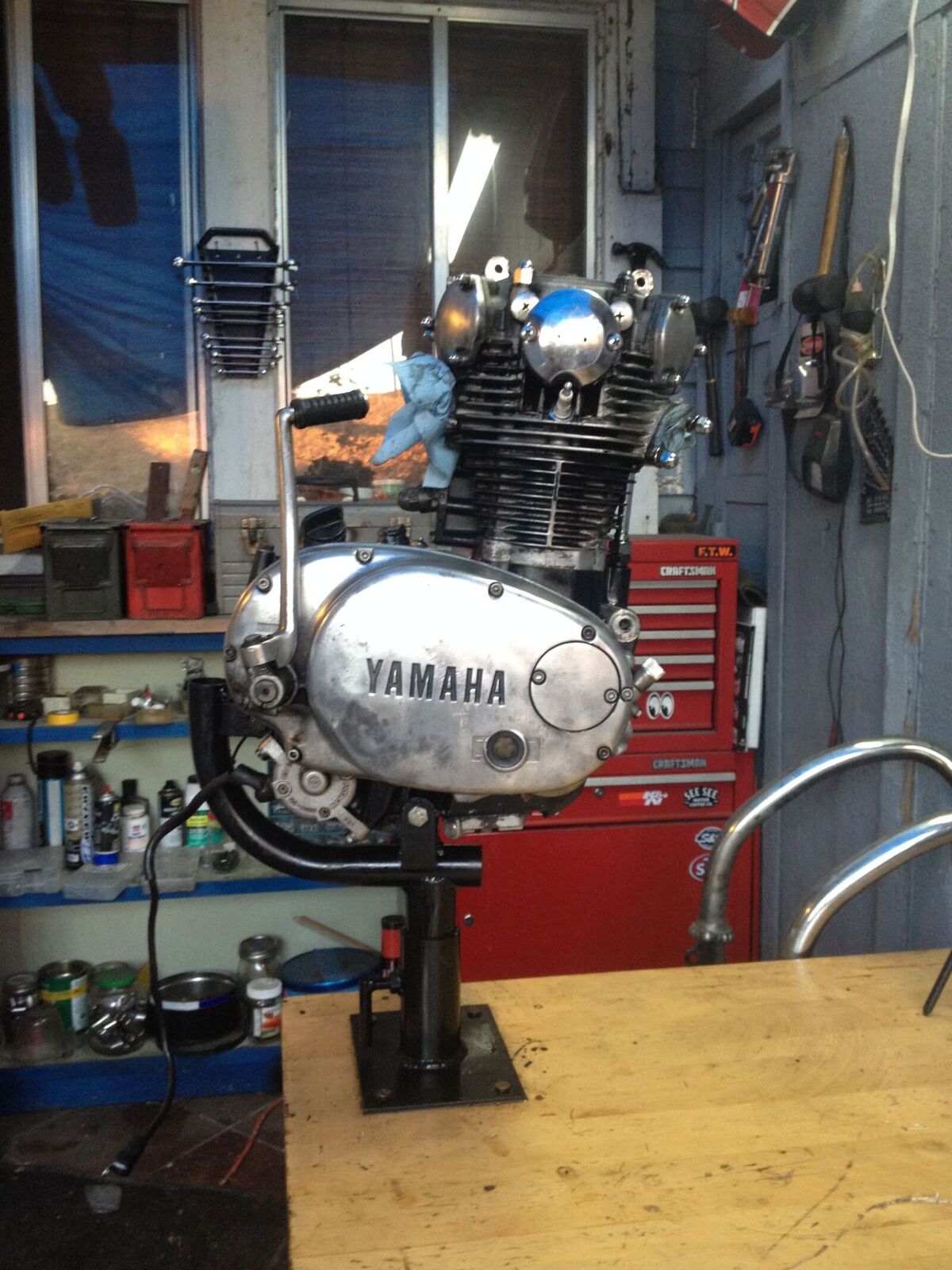

On the stand (heaaaavy motherfugger). I like that this stand rotates, but already I forsee it being a PITA when it comes time to torque this all back up as the rotation lock aspect of it isn't quite strong enough not to turn when I put my back into it...Seemed like a good design to spring for after reading that the TC bros one might be flimsy, but let me serve as a bit of a warning. Will probably have to compensate by drilling holes into it so that it locks properly.

Head cover w/ rocker arms (unclear if it's actually necessary to take these off for any reason though manual specifies I should...probably for inspection?):

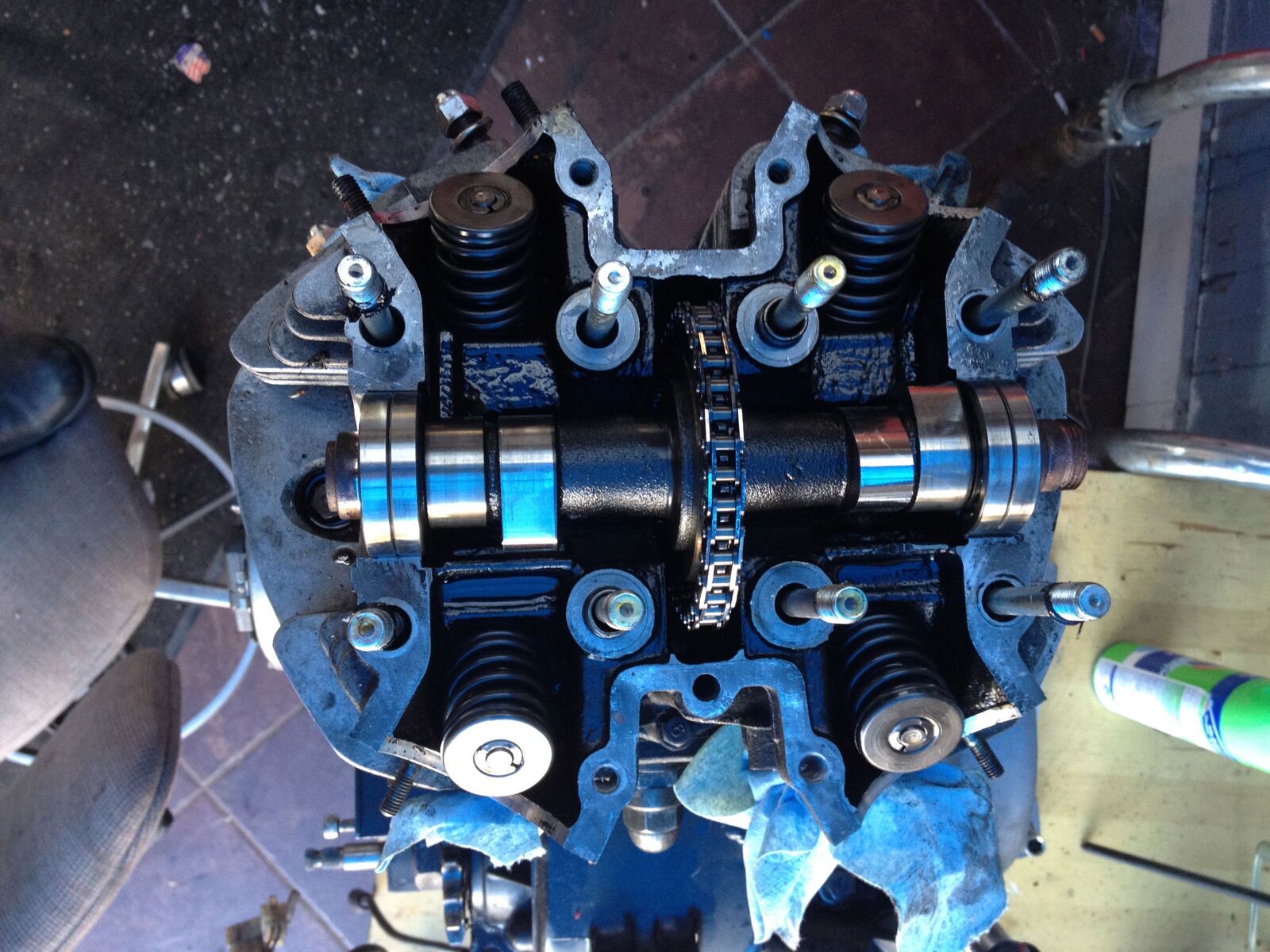

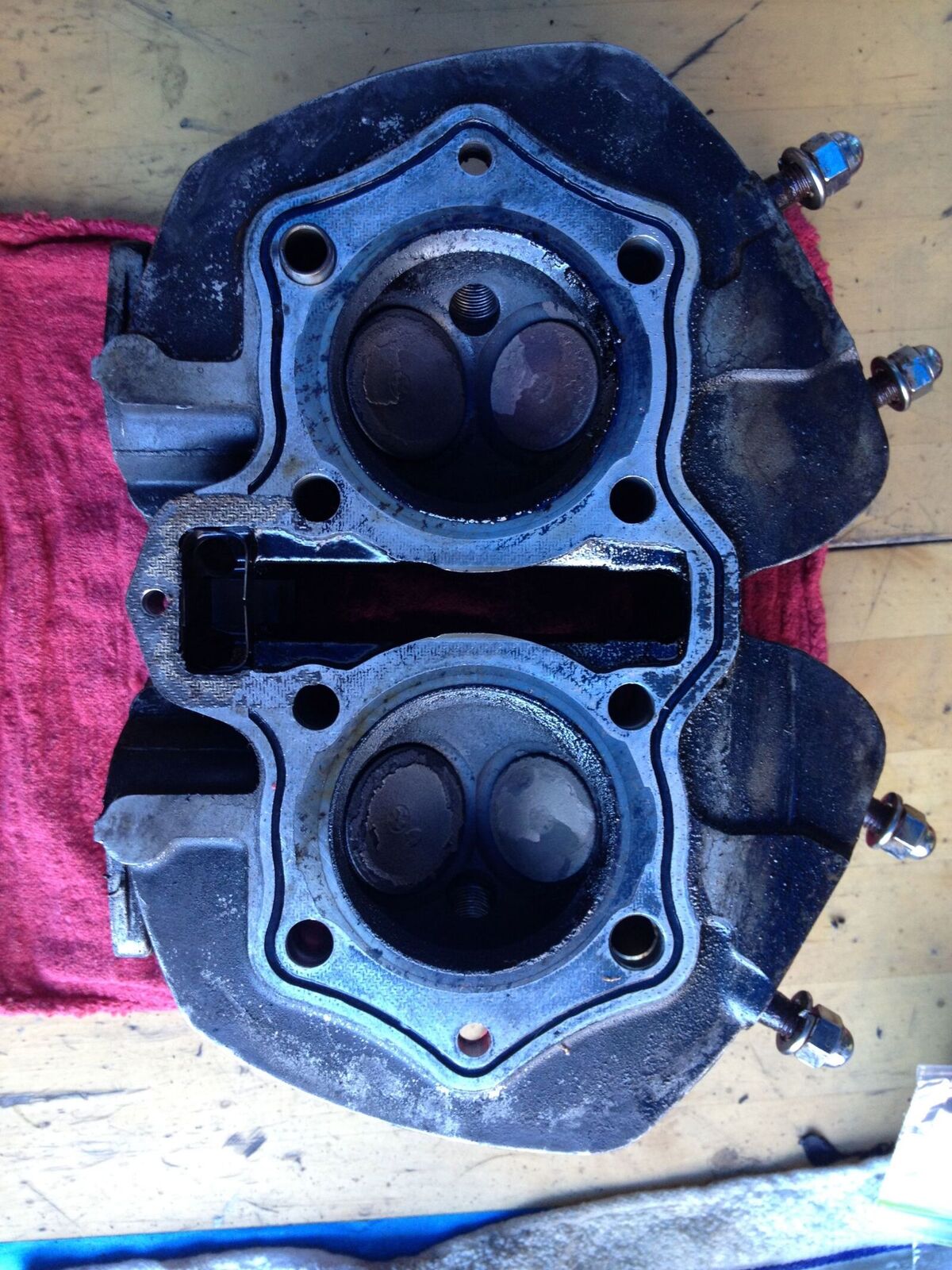

Cyl head & cam:

Cam lobes:

Cam:

Removed head:

Close up of valves:

Filthy:

Pistons - please have a look at the marks on them and tell me if I need a new set:

RH piston:

LH piston:

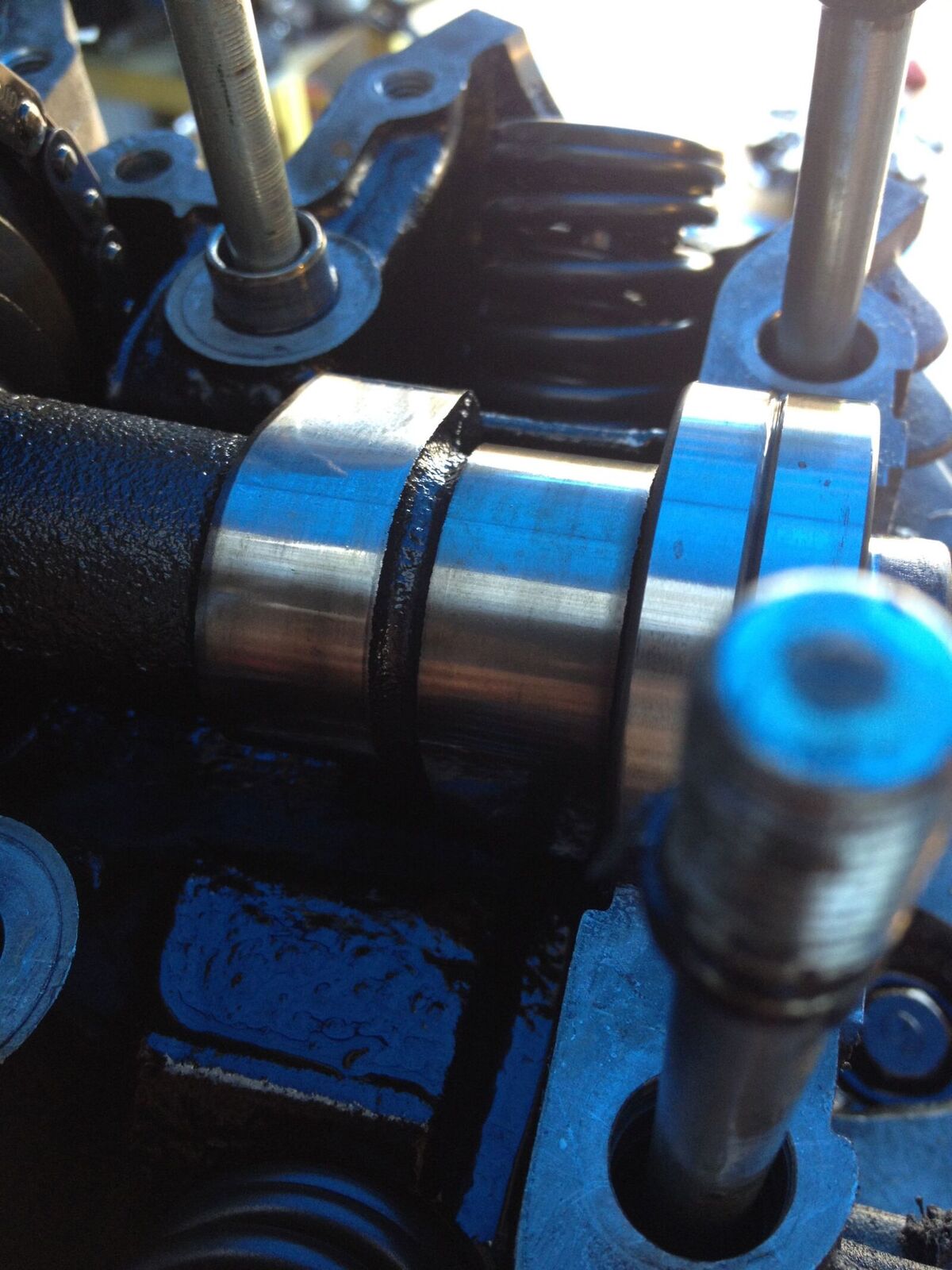

Hooray! I correctly diagnosed something! I found the plastic part of the cam chain guide down towards the sump, actually resting on the crank!

The chain was going against the bare metal of the guide. Not for very long though - most likely as soon as I heard the noise the plastic had just dropped down and I only ran it for a few minutes to listen with the stethoscope after getting it home. You can see the wear against the metal is minimal, and the cam chain itself actually looked fine. Obviously I'm replacing both.

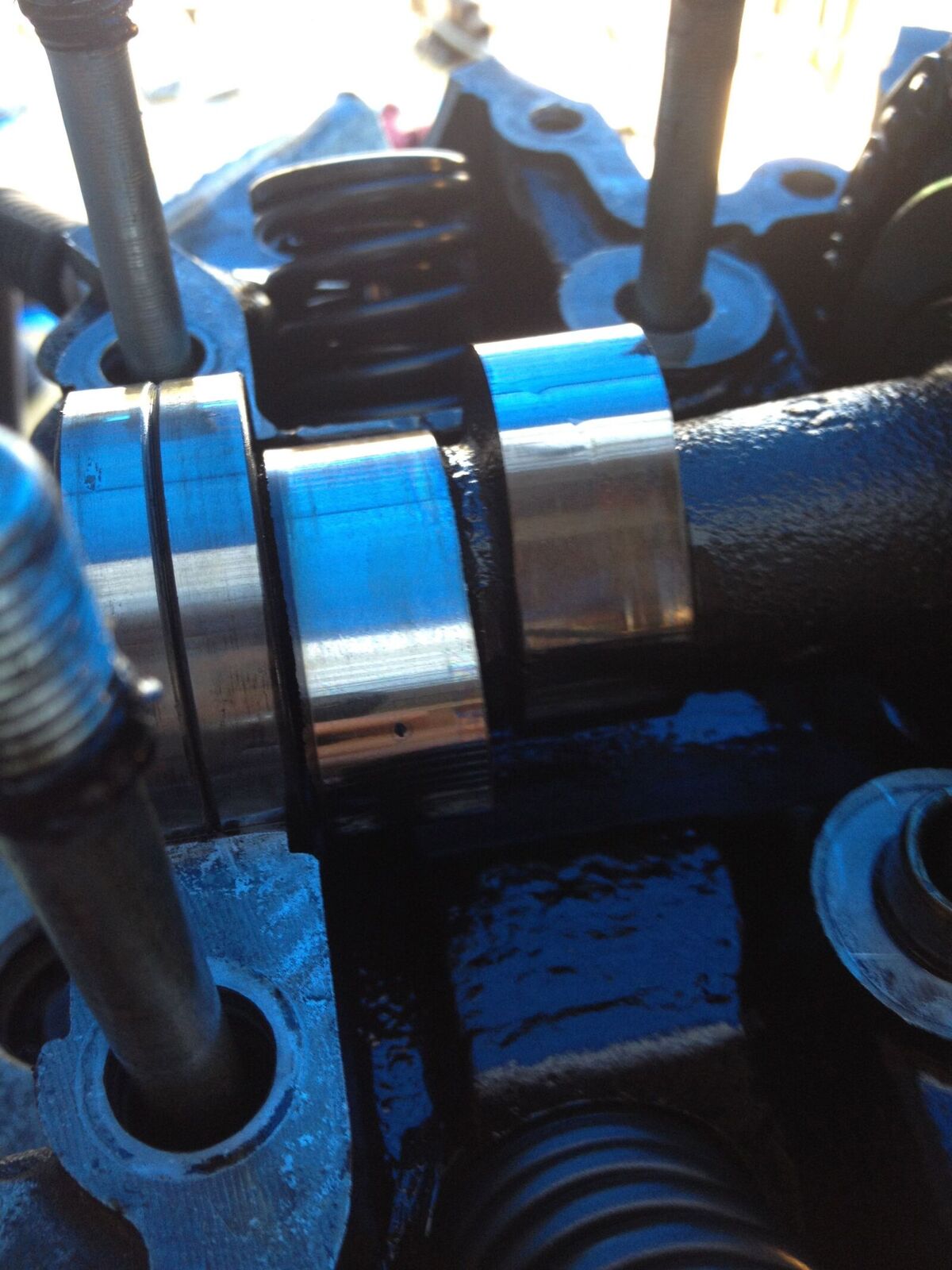

RH barrel was smooth and still had those nice factory machining marks. Hard to tell in the pics.

LH barrel was not horribly scratched up (no vertical scratch marks or marring), but seemed to have some kind of funky markings on them that went horizontally. Looked more like grime or scorch marks, but was flush. There are oil droplets here not to be mistaken for pitting:

The spread!

And that's where I'm at for now. Next step is to remove pistons and then I'll be cleaning all the parts and doing manual-prescribed diagnoses on the top end. I'm very nervous about all of this since it's my first time in an engine. Taking it apart was easy enough with the patience in knowing that it's alright if I just do one thing a day if I wanted and a reminder to always just STOP if I run into something I don't know how to do. I'm sure the language will get colorful when it comes time to putting all this together again!

Questions:

1. Do I need to pull the rockers at all like the manual says?

2. Can I wash things like the cylinder head & cover with water (like in a shop sink or bucket) if I dry them all quickly with acetone/air compressor? I've been using pine sol and scrubbing bubbles as degreasers but have been worried about getting all this stuff wet.

3. My plan was to fix the broken part, measure and make sure everything is up to spec, clean everything, and then put it back together again. Is it worth the trouble to go into the bottom end just to check to make sure everything is clean and within spec down there or should I embrace more of an "if it ain't broke, don't fix it" mentality?

Looking forward to hearing what you have to say! Any and all advice is welcome.

Thanks,

Lucky

Just a month ago, I was riding to work when I heard a brand new sound from the top end. Turned around home and listened up with a stethoscope and it sounded like the cam chain guide had rubbed through to the metal. After some colorful language, I resigned to pull the engine and give it as good a goin' through as I can.

I'm going by the original '82 factory manual (the one with it's own yamaha part number) and searching through here when I get stuck. I'm taking my time with all of this because I've broken things through impatience before. Here we go:

Complete:

Stripping down:

On the stand (heaaaavy motherfugger). I like that this stand rotates, but already I forsee it being a PITA when it comes time to torque this all back up as the rotation lock aspect of it isn't quite strong enough not to turn when I put my back into it...Seemed like a good design to spring for after reading that the TC bros one might be flimsy, but let me serve as a bit of a warning. Will probably have to compensate by drilling holes into it so that it locks properly.

Head cover w/ rocker arms (unclear if it's actually necessary to take these off for any reason though manual specifies I should...probably for inspection?):

Cyl head & cam:

Cam lobes:

Cam:

Removed head:

Close up of valves:

Filthy:

Pistons - please have a look at the marks on them and tell me if I need a new set:

RH piston:

LH piston:

Hooray! I correctly diagnosed something! I found the plastic part of the cam chain guide down towards the sump, actually resting on the crank!

The chain was going against the bare metal of the guide. Not for very long though - most likely as soon as I heard the noise the plastic had just dropped down and I only ran it for a few minutes to listen with the stethoscope after getting it home. You can see the wear against the metal is minimal, and the cam chain itself actually looked fine. Obviously I'm replacing both.

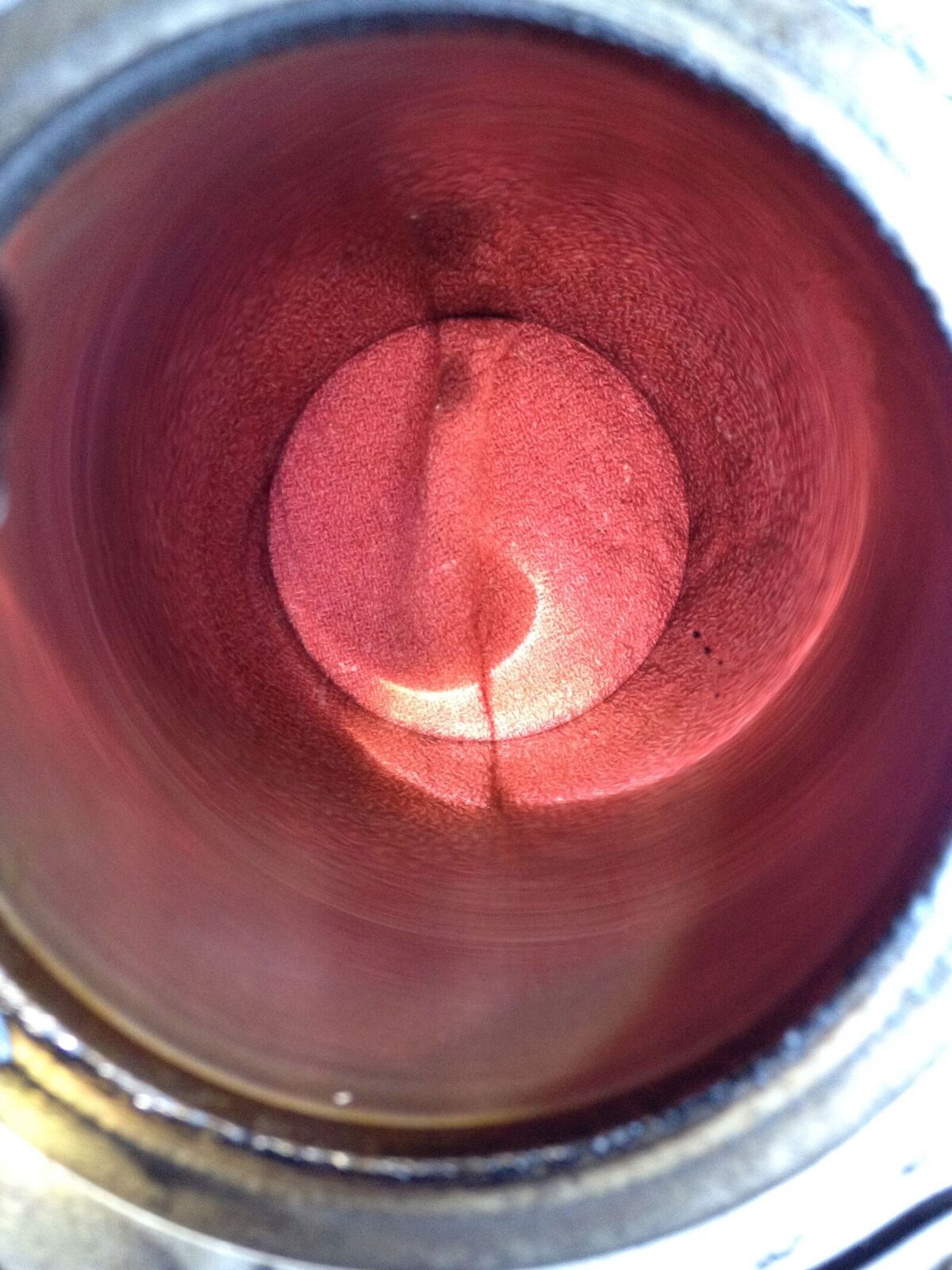

RH barrel was smooth and still had those nice factory machining marks. Hard to tell in the pics.

LH barrel was not horribly scratched up (no vertical scratch marks or marring), but seemed to have some kind of funky markings on them that went horizontally. Looked more like grime or scorch marks, but was flush. There are oil droplets here not to be mistaken for pitting:

The spread!

And that's where I'm at for now. Next step is to remove pistons and then I'll be cleaning all the parts and doing manual-prescribed diagnoses on the top end. I'm very nervous about all of this since it's my first time in an engine. Taking it apart was easy enough with the patience in knowing that it's alright if I just do one thing a day if I wanted and a reminder to always just STOP if I run into something I don't know how to do. I'm sure the language will get colorful when it comes time to putting all this together again!

Questions:

1. Do I need to pull the rockers at all like the manual says?

2. Can I wash things like the cylinder head & cover with water (like in a shop sink or bucket) if I dry them all quickly with acetone/air compressor? I've been using pine sol and scrubbing bubbles as degreasers but have been worried about getting all this stuff wet.

3. My plan was to fix the broken part, measure and make sure everything is up to spec, clean everything, and then put it back together again. Is it worth the trouble to go into the bottom end just to check to make sure everything is clean and within spec down there or should I embrace more of an "if it ain't broke, don't fix it" mentality?

Looking forward to hearing what you have to say! Any and all advice is welcome.

Thanks,

Lucky