Interesting. Just tried mine and it does start, but gets stuck about a quarter of the way down. Had to beat it off with a rubber mallet. Measured..... the OEM holes for the studs are about 12mm. The big bore holes are right at 10mm.... 2mm less than the original cylinders. Since the studs are 10mm... what we have is almost an interference fit between the holes and studs. I think I'll drill mine out to 12mm. Didn't really expect any problems.... shoulda' known better huh?I also tried a second one and it is the same way. I am in trouble. I already sold four of these kits.

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

For Sale - Big bore kits $350???

- Thread starter Infantilebehavior

- Start date

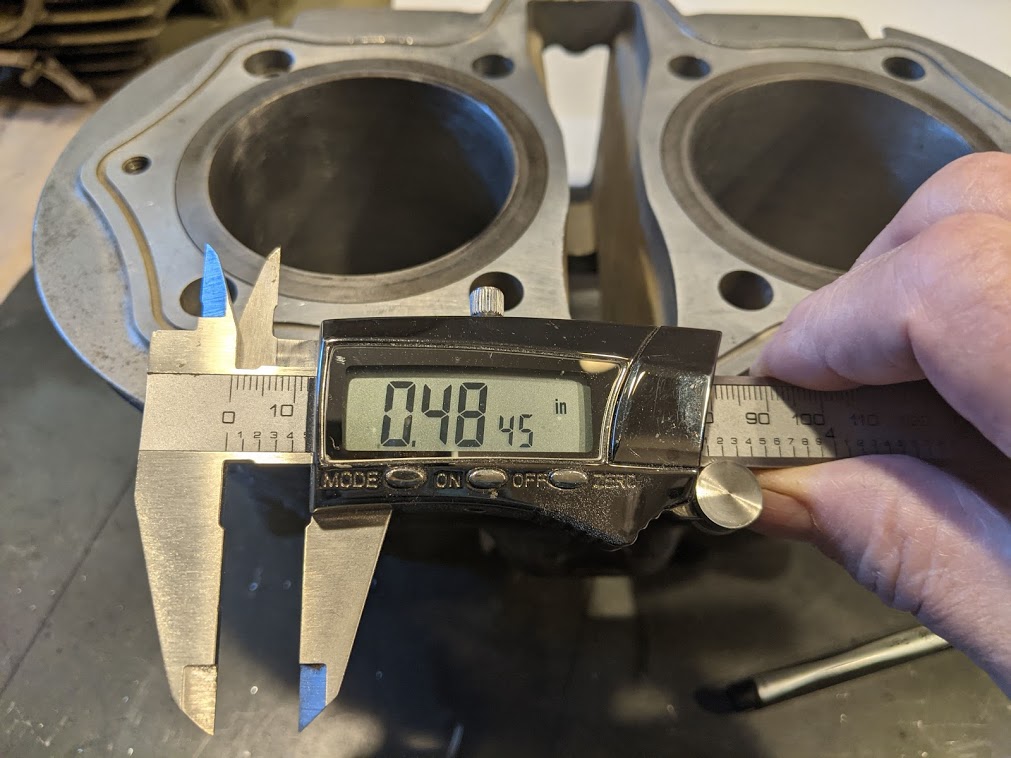

Time to fire up the drill press.Just checked mine, same issue. BBK holes measure right at 10mm, stock cylinder on bench holes measure a fat 11mm

OK... just got a good check on an OEM cylinder. Holes are 12.3mm.... or .484"....

I think anything over 11mm would work. Might be sticky and fiddly though. Think I'll just go a full 12mm.

I think anything over 11mm would work. Might be sticky and fiddly though. Think I'll just go a full 12mm.

I checked the holes in one of my kits and they are spot on 10mm. Studs went through OK.

Try it with the studs installed in the case?Studs went through OK.

Good point.Try it with the studs installed in the case?

Don't have a motor apart or a set of cases with studs in. Probable would be a tough go. Looks like either drill the cylinders or slot the stud and put them in after cylinder is on. Or both.

I asked in a different thread about the end quality about how XS Performance products versus OEM, I was initially enquiring about rocker arms & shafts, seems things may be off a touch across the board?

Daniel.

Daniel.

If the reason they are being sold at a discount is because of the hole defect it would have been nice to know. If you have a drill press and a 12mm drill bit not a big deal. If you don't have either one that's a different thing. To be honest I would still buy it if I had known. It does shake my confidence in the quality of the rest of the kit.

Maybe that's they way they have always been. There are a few guys that bought them years ago. Hopefully they will comment.

Maybe that's they way they have always been. There are a few guys that bought them years ago. Hopefully they will comment.

15 minuets on the drill press is well worth saving 3 bills.

Yeah, it's a repop. What I don't get is why they were drilled at 10mm. Seems they either had an OEM cylinder to copy or some original drawings. Either one would call for 12mm holes. Damned odd. Makes me wonder if there's other snakes in the grass waiting?Jim, if this was a 650 core block why do you think the stud holes were smaller? Or is this a repop block?

Exactly. Had I known the holes are too small, I'd still buy it. I'll wait for @650trader to jump in before commenting further, but if this was a known issue....If the reason they are being sold at a discount is because of the hole defect it would have been nice to know.

What about the alignment bushings? Will that work with 12 mm drill?

I tried the bushings... they fit just fine. At least in my BBKWhat about the alignment bushings? Will that work with 12 mm drill?

Seems a little shady to me to be selling these at a discounted price if there’s a known discrepancy, doesn’t bode well for a new trader.

Transparency goes a long way in my book.

Daniel.

Transparency goes a long way in my book.

Daniel.

I seem to recall a recent build thread with a guy installing one and him saying he had a heck of a time getting it on?? Ring any bells???

I mean as long as the holes are drilled in the correct location even a little finesse and a hand drill motor should be able to get the job done.

still a bummer the jobs gotta get done to begin with though. Nothing like a beat to fit finish on some high performance parts haha.

I’ll measure mine later today.

PS... if the issue wasn’t known, that is some TERRIBLE QC work on both the part of the manufacturing company and the seller. (Unless that was how it was spec-ed to production)

If someone’s got one that measures correctly at least it could be narrowed down to a batch being bad and not all

I mean as long as the holes are drilled in the correct location even a little finesse and a hand drill motor should be able to get the job done.

still a bummer the jobs gotta get done to begin with though. Nothing like a beat to fit finish on some high performance parts haha.

I’ll measure mine later today.

PS... if the issue wasn’t known, that is some TERRIBLE QC work on both the part of the manufacturing company and the seller. (Unless that was how it was spec-ed to production)

If someone’s got one that measures correctly at least it could be narrowed down to a batch being bad and not all

So... looking down the holes... they're pretty ratty... a dull wood bit comes to mind....

Decided to start small and just clean 'em up. Tried a 27/64th" bit. That's about 10.5mm. My press only has a plunge depth of 3" so I had to drill from both sides. Watch your alignment guys if you have to do the same. Anyway.... it worked. Just takin' 'em out a half mm and cleaning the holes up is enough. Slid on and off nice and free.

Decided to start small and just clean 'em up. Tried a 27/64th" bit. That's about 10.5mm. My press only has a plunge depth of 3" so I had to drill from both sides. Watch your alignment guys if you have to do the same. Anyway.... it worked. Just takin' 'em out a half mm and cleaning the holes up is enough. Slid on and off nice and free.

seem to recall a recent build thread with a guy installing one and him saying he had a heck of a time getting it on?? Ring any bells???

Yeah, that was me. I eventually worked it on but it required slow, light tapping down over the threaded ends of the studs to get it over. If I were smarter I would have measured the holes and clearances. I measured the pistons and bores ironically, but I guess it never even dawned on me that the holes on the kits could be out of spec. I know these kits have a very good reputation, but that's shame on me.

To be honest, I don't know how the hell I'd get it off again.

Similar threads

- Replies

- 277

- Views

- 24K

- Replies

- 5

- Views

- 858