-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1978 XS650 Special Project

- Thread starter Melnic

- Start date

Yes, I'd be very interested in what you received.Please let us know what you discover

Last edited:

Looks like things are unchanged.

Thread depth is about 8-10mm

Removed the top mount, coils, condenser and neutral switch

I"m cleaning all the bullet connectors as I pull them off cause I know I won't be wanting to do that as I'm putting things back together.

Tomorrow I'll be loosening the rear wheel and pull the chain off.

Unless there are interruptions, should have it pulled and onto the stand this weekend.

Primary coils were 4.3ohms

Orange wire to caps were 13.3K on both (I have NGK resistive caps installed)

Parts from each section are going in zip lock bags. then into a cardboard box.

If fasteners can be put back on the bike (like the ones holding the foot peg brackets) I do so. Otherwise they get re assembled onto their part and put in the bag.

Idea for me is that when I"m done putting it back together, all bags should be empty.

Thread depth is about 8-10mm

Removed the top mount, coils, condenser and neutral switch

I"m cleaning all the bullet connectors as I pull them off cause I know I won't be wanting to do that as I'm putting things back together.

Tomorrow I'll be loosening the rear wheel and pull the chain off.

Unless there are interruptions, should have it pulled and onto the stand this weekend.

Primary coils were 4.3ohms

Orange wire to caps were 13.3K on both (I have NGK resistive caps installed)

Parts from each section are going in zip lock bags. then into a cardboard box.

If fasteners can be put back on the bike (like the ones holding the foot peg brackets) I do so. Otherwise they get re assembled onto their part and put in the bag.

Idea for me is that when I"m done putting it back together, all bags should be empty.

Last edited:

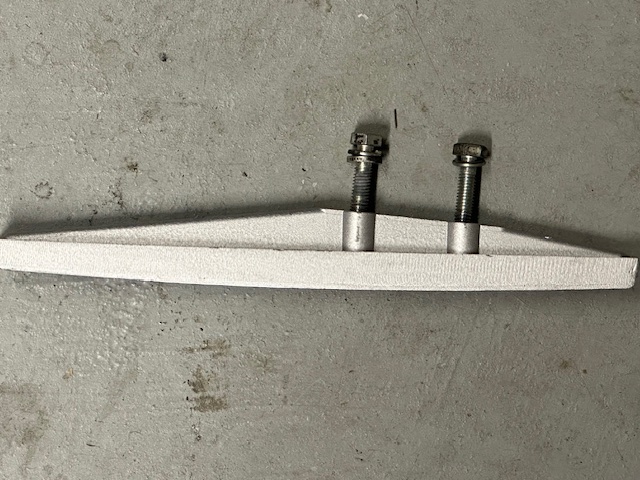

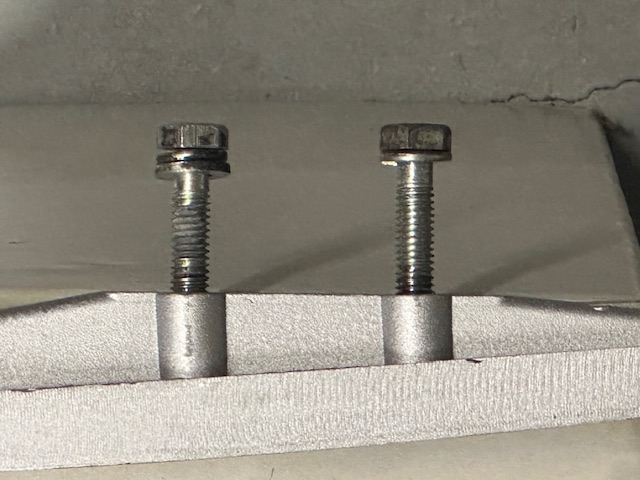

Yes, it doesn't look like they've changed the casting much, if any, but at least your bolts look about at the right angle to the mating surface (should be perpendicular to it). Maybe if you chase the threads with an M6 bottoming tap to make sure they're clean and deep enough, you'll be OK.

Parts from each section are going in zip lock bags. then into a cardboard box.

If fasteners can be put back on the bike (like the ones holding the foot peg brackets) I do so. Otherwise they get re assembled onto their part and put in the bag.

Idea for me is that when I"m done putting it back together, all bags should be empty.

Sounds like you've done this before. IMHO, being organised is a major part of working on motorbikes, if you want to complete the project with a bike that works. I put fasteners, like footpeg mounting bolts, loosely back where they belong. If there's an assembly, like the wheel spindle with nuts, washers, spacers and so forth, I put the bits together in the correct order to wait for re-assembly. Little plastic bags of bits, with a note of what & where. Makes picking the project up again so much more straightforward.

The bolt hole alignment on that guide looks proper to meLooks like things are unchanged.

Thread depth is about 8-10mm

Removed the top mount, coils, condenser and neutral switch

I"m cleaning all the bullet connectors as I pull them off cause I know I won't be wanting to do that as I'm putting things back together.

Tomorrow I'll be loosening the rear wheel and pull the chain off.

Unless there are interruptions, should have it pulled and onto the stand this weekend.

Primary coils were 4.3ohms

Orange wire to caps were 13.3K on both (I have NGK resistive caps installed)

Parts from each section are going in zip lock bags. then into a cardboard box.

If fasteners can be put back on the bike (like the ones holding the foot peg brackets) I do so. Otherwise they get re assembled onto their part and put in the bag.

Idea for me is that when I"m done putting it back together, all bags should be empty.

View attachment 256417View attachment 256418

Bike has a riveted master link on main chain.

Keep or replace with clip type?

Also, do I remove the starter before pulling the engine?

Or remove the boot (does not look easy) and disconnect the power cable to the starter?

Keep or replace with clip type?

Also, do I remove the starter before pulling the engine?

Or remove the boot (does not look easy) and disconnect the power cable to the starter?

Last edited:

Looks like they fixed the issue, they look to be in pretty good alignment compared to their old defective ones.Looks like things are unchanged.

Thread depth is about 8-10mm

Removed the top mount, coils, condenser and neutral switch

I"m cleaning all the bullet connectors as I pull them off cause I know I won't be wanting to do that as I'm putting things back together.

Tomorrow I'll be loosening the rear wheel and pull the chain off.

Unless there are interruptions, should have it pulled and onto the stand this weekend.

Primary coils were 4.3ohms

Orange wire to caps were 13.3K on both (I have NGK resistive caps installed)

Parts from each section are going in zip lock bags. then into a cardboard box.

If fasteners can be put back on the bike (like the ones holding the foot peg brackets) I do so. Otherwise they get re assembled onto their part and put in the bag.

Idea for me is that when I"m done putting it back together, all bags should be empty.

View attachment 256417View attachment 256418

Last edited:

I leave the starter attached and pull the motor. You sometimes find it easier to remove the cable @ the solenoid.Bike has a riveted master link on main chain.

Keep or replace with clip type?

Also, do I remove the starter before pulling the engine?

Or remove the boot (does not look easy) and disconnect the power cable to the starter?

View attachment 256468

The master link issue is a personal preference thing; I prefer riveted.

Leave the starter on for now unless you want a bunch of oil leaking out. Once it’s on a stand it’s easier to pull to replace the oil seal if desired.

I always leave the starter cable connected to the motor and disconnect it up at the solenoid. Once the motor is out, you will want to inspect the cable's connection. When I got my '78, the starter didn't work and that was because the cable connection at the motor was all rusty. The rubber protection boot had split and allowed water in. I cleaned it all up, replaced the boot, and it's worked fine ever since.

Personally, I've always used clip type master links on drive chains. You will need a replacement link of some sort because to remove the one that's on there, you're going to have to drill or grind the riveted pins, and that will destroy the link. Hopefully you can I.D. the chain and still get a replacement master link for it. If not, no big deal. You can get a nice regular D.I.D. chain (not o-ring) for around $40. These bikes aren't that powerful (about 50hp) so I don't see the need for an expensive o-ring chain. A good quality normal chain works fine and the D.I.D. one is supposed to be one of the best.

Personally, I've always used clip type master links on drive chains. You will need a replacement link of some sort because to remove the one that's on there, you're going to have to drill or grind the riveted pins, and that will destroy the link. Hopefully you can I.D. the chain and still get a replacement master link for it. If not, no big deal. You can get a nice regular D.I.D. chain (not o-ring) for around $40. These bikes aren't that powerful (about 50hp) so I don't see the need for an expensive o-ring chain. A good quality normal chain works fine and the D.I.D. one is supposed to be one of the best.

Engine is out. Boys lifted it and set it onto the bike lift, then I moved the bike back and they lifted it onto the stand that is on my workmate.

This is a TCbros XS650 stand. The holes are way too tight and I had to drill out all the holes in it.

Especially the ones that you mount the engine to so you have some wiggle room.

Yup, that starter boot looked good from outside, but once I touched it, its all crusty and the inside is all rusty.

I will pull the starter while I have the engine out and put new brushes and clean the copper inside.

Need to order the brushes.

If I can get a new boot, that would be something to get also. Maybe even a cable. I have cable/rings I think in my boat supplies. Will have to look.

This is a TCbros XS650 stand. The holes are way too tight and I had to drill out all the holes in it.

Especially the ones that you mount the engine to so you have some wiggle room.

Yup, that starter boot looked good from outside, but once I touched it, its all crusty and the inside is all rusty.

I will pull the starter while I have the engine out and put new brushes and clean the copper inside.

Need to order the brushes.

If I can get a new boot, that would be something to get also. Maybe even a cable. I have cable/rings I think in my boat supplies. Will have to look.

When I pulled my starter, I found the same.... rust, and lots of it...

https://www.xs650.com/threads/jims-1980-sg-miss-september.50545/post-551327

When I took the starter apart though, everything was like new internally, including the brushes. Hopefully yours is the same. A word of caution: the end cap tie screws are no longer available, in case you have to drill the heads off like I did. I found that 10/32 screws fit just fine.

If you can't find them anywhere else, Aircraft Spruce carries the boots.

https://www.xs650.com/threads/jims-1980-sg-miss-september.50545/post-551327

When I took the starter apart though, everything was like new internally, including the brushes. Hopefully yours is the same. A word of caution: the end cap tie screws are no longer available, in case you have to drill the heads off like I did. I found that 10/32 screws fit just fine.

If you can't find them anywhere else, Aircraft Spruce carries the boots.

Thx for the input.

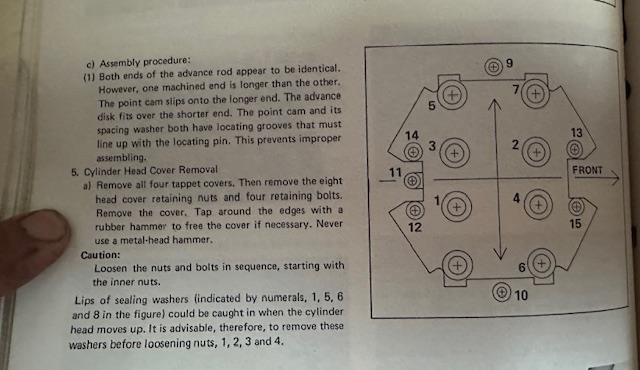

On the cover, this is a pic of the service manual that I got with the bike.

Not sure it makes sense (figure referred to in the cylinder head removal) cause the bolt order in the pic is EXACTLY the same as the assembly order when torquing down.

I thought that you would loosen the outer lower torque/smaller bolts first which would be opposite the assembly order.

Input?

On the cover, this is a pic of the service manual that I got with the bike.

Not sure it makes sense (figure referred to in the cylinder head removal) cause the bolt order in the pic is EXACTLY the same as the assembly order when torquing down.

I thought that you would loosen the outer lower torque/smaller bolts first which would be opposite the assembly order.

Input?

I remove the outside 4 large acorn nuts first and take the rubber/metal washers off them. If you loosen all the fasteners, the top cover can rise up a little and pinch those rubber/metal washers in place, making them harder to remove. Also, once you get to it, the lower fitting for the oil pipe needs to come off or the cylinders won't lift off. It overhangs them a little and will stop them from lifting.

When I pulled my starter, I found the same.... rust, and lots of it...

https://www.xs650.com/threads/jims-1980-sg-miss-september.50545/post-551327

When I took the starter apart though, everything was like new internally, including the brushes. Hopefully yours is the same. A word of caution: the end cap tie screws are no longer available, in case you have to drill the heads off like I did. I found that 10/32 screws fit just fine.

If you can't find them anywhere else, Aircraft Spruce carries the boots.

View attachment 256484

View attachment 256485

How do I get to change the power stud? Do I just use parts from hardware store?

I can't seem to loosen the big screws to remove the outside core so I can get to power stud or will just cutting it off do what I need to replace it?

Hard to believe, but that's the original stud. Wire brush and it cleaned up like new.How do I get to change the power stud? Do I just use parts from hardware store?

I can't seem to loosen the big screws to remove the outside core so I can get to power stud or will just cutting it off do what I need to replace it?

I had to drill the heads off the screws to get the starter apart, and like I said, new ones are NLA

Cut master link off cam chain, then installed a master link between the two and pulled the new chain thru. I purchased a spare so I could do this.

I measured the new chain and the old one.

The original Cam was about 4.5mm longer than the new one I got.

When I put the cam alignment mark at 12:00 to the engine, the Timing mark was about 2mm retarded showing how the cam chain I guess was stretched some.

When adjusting the points, I had the adjustment all the way to one end and actually had to open the points gap up some just to get the timing set.

This is the main reason I am doing this work.

I measured the new chain and the old one.

The original Cam was about 4.5mm longer than the new one I got.

When I put the cam alignment mark at 12:00 to the engine, the Timing mark was about 2mm retarded showing how the cam chain I guess was stretched some.

When adjusting the points, I had the adjustment all the way to one end and actually had to open the points gap up some just to get the timing set.

This is the main reason I am doing this work.