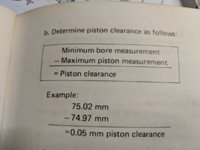

I apologise for being so inept but I am still struggling with the question of whether or not my '78 SE needs a rebore and 1st oversize pistons. I posted a photo last week showing a .009" feeler gauge inserted between my piston and the cylinder wall (pic 1). I had made my mind up to take it back to the shop and get them to measure it with the appropriate instruments but I decided to attempt to resolve the issue myself. Following advice from the forum, (much appreciated as always), I turned the jugs upside down and installed the pistons in the cylinders (pics 2 & 3). I now found that I could barely insert a .002" feeler between the piston and cylinder wall (pic 4). I realise the cost of the measurements will be insignificant but I hesitate to turn up at my local shop with a set of paranoic questions that leave me looking like a yabbie, (which is how I am beginning to feel). Obviously, I don't want to rebore and purchase new pistons if I don't need to. Have a look at the pictures and tell me what you think.

Sorry about the focus in pic 2 - looked fine without my glasses!

Sorry about the focus in pic 2 - looked fine without my glasses!

![IMG_0723[1].JPG](/data/attachments/102/102789-c87eb059f2b57f83dcd1c11e86877b52.jpg)