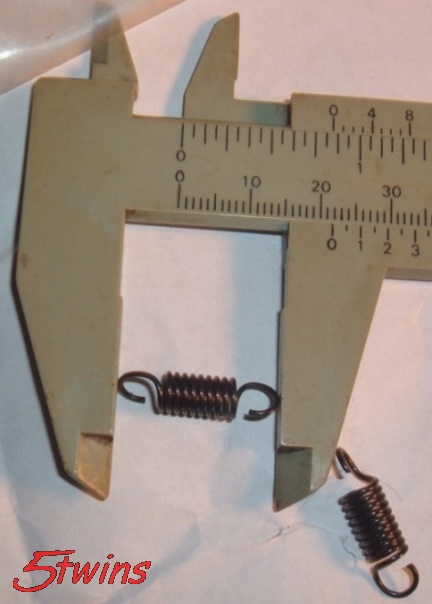

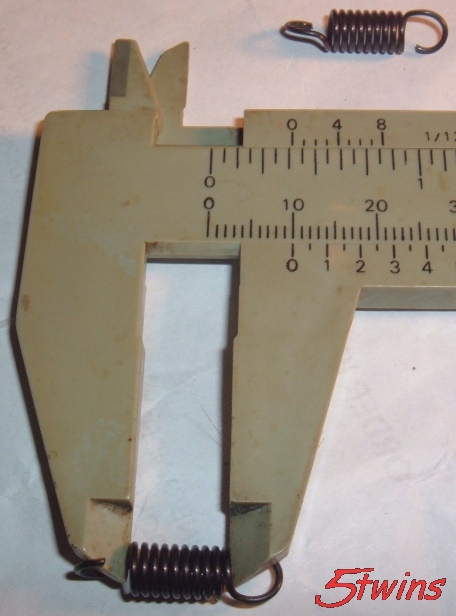

OK, I've got some spring info for you. The total length appears to be just under 22mm. Length of just the spring coils is about 10mm, they have a diameter of about 5.6mm, and there are 10 of them. The wire diameter or thickness is .75 to .80mm and the hooks on the ends are bent out at 90° to one another. Turns out I also had some from MikesXS. The only difference appears to be the silver color, all the other measurements look to be the same, and they have the same number of coils ......

And the part number shown on the package in the first pic is the correct one for the spring. It wasn't easy to find that. Of all the manuals I've downloaded, only one showed it. Most just shown the advance unit, or "Governor" as they call it, as an "assembly".

And the part number shown on the package in the first pic is the correct one for the spring. It wasn't easy to find that. Of all the manuals I've downloaded, only one showed it. Most just shown the advance unit, or "Governor" as they call it, as an "assembly".