andrewc

XS650 Enthusiast

tore into the clutch side today, to remove clutch springs and replace with new, and noticed something funky. i have added 3 photos of the issues, circled and pointed to. can anyone tell me what the spring (that is broken) attaches to, and i take it im going to need to remove the basket in order to get to said parts in need of attention? this means i will probably need to order a clutch tool as well yes? if someone could post a photo or two of how everything behind the clutch basket is supposed to be, that would help a lot. i have already replaced the clutch discs a while back and everything worked fine, but under heavy acceleration, i could feel the clutch slipping, which is why im back in the right side cover today. (should've done more research on clutch springs before i replaced the discs.) any help and explanation/pictures will be greatly appreciated. thank you.

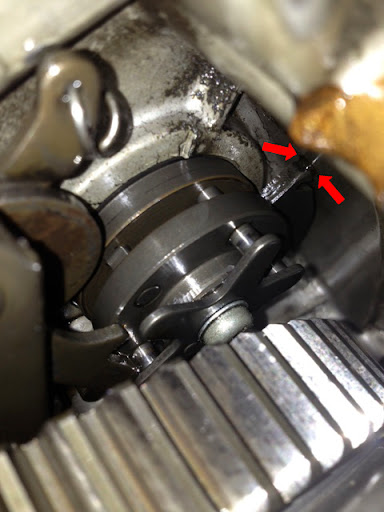

first photo shows the broken spring on the arm (not sure what it does) and the gouge its made in the engine case.

second photo shows the other arm (the the right of basket) that is touching the engine case.

third photo shows the broken spring hanging on arm.

first photo shows the broken spring on the arm (not sure what it does) and the gouge its made in the engine case.

second photo shows the other arm (the the right of basket) that is touching the engine case.

third photo shows the broken spring hanging on arm.