If you're using the '78 spec for the intakes (.004") then they probably will tick. They did on mine but closing them up just .001" to .003" quieted them right down. It's accepted practice, by the way, to use .003" for the intakes on all years/models.

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1978 XS650 Special Project

- Thread starter Melnic

- Start date

My Red Bike with commando (quiet) muffs has 0.004" intake and I hear the ticking. My tracker with Omars exhaust (loud) has 0,004" intake setting and I don't hear any ticking.If you're using the '78 spec for the intakes (.004") then they probably will tick. They did on mine but closing them up just .001" to .003" quieted them right down. It's accepted practice, by the way, to use .003" for the intakes on all years/models.

Last edited:

See my edited post...I'm able to run .004" now on the '78 intakes because I installed those elephant foot adjuster screws when I did the topend.

Reading all the posts and specs and such I had split the difference on what I read. (.003 intake/.006 exhaust with .002/.004 minimums)If you're using the '78 spec for the intakes (.004") then they probably will tick. They did on mine but closing them up just .001" to .003" quieted them right down. It's accepted practice, by the way, to use .003" for the intakes on all years/models.

my notes I wrote I set it to .0025" on intake and .005 on Exhaust.

Tomorrow I'll have time to check them first, then reset them.

I'll swear its the left exhaust so I'll find out tomorrow.

The bigger the clearance, the more oil you let in, so bigger is better as long as it doesn't make too much noise. .006" is usually good on the exhausts (no excessive noise) so I don't go smaller on them. With standard, stock rockers, I use .003" on the intakes. I wish I could go bigger but they make noise if I do. Eventually, I'll put the elephant feet adjusters in my '83 as well and then I'll be able to use the bigger setting on the intakes. But that will have to wait for a topend teardown. Unfortunately, that may come sooner than I'd like. Even though the topend was done only a few thousand miles ago on that bike, it was more than a dozen years ago, lol. An Athena head gasket was used and as you may have heard me mention, it seems they have an age limit. After about 10 years or so, they go bad and start leaking. And that's exactly what seems to be happening.

so, I checked the clearances and they were all at least +.002" larger than what I had set them. I had set them after I had torqued down the head bolts and before I put the engine in the bike. I did not check them after starting up the engine for the first time.

I set the clearances of them all and warmed up the engine best I could in the garage.

Will have to test ride likely thursday when I"m off in the morning and weather is good.

I set the clearances of them all and warmed up the engine best I could in the garage.

Will have to test ride likely thursday when I"m off in the morning and weather is good.

After having the topend all apart, it seems it takes a few hundred miles for everything to settle back in. So, you'll want to do several valve clearance checks and even more important, several head bolt re-torques. All those new gaskets will be getting compressed, and the head bolts will become loose. Heat cycles also play a big part in this. I like to let a newly assembled motor sit at least over night and then check the head bolt torques again. This is before it's even been run. Then after it has been run and put through several heat cycles, I check the torques again. I like to do 3 or 4 torque checks in the first couple thousand miles. Eventually, as the gaskets get fully compressed, the torques will stabilize and stop getting loose. After that, I still check the head bolt torques, but only about once a year.

Thx 5twins.

Am I just setting torque wrench and then following the pattern and tightening or am I to back off some on all of them then tighten following pattern?

Also, I was following service manual I had that came with bike and it shows 25ft-lbs but found posts recently where you mention set to 30-35. I did not apply any anti seize to the threads. I just brushed them clean before putting back together. Please advise. thx

Today, arrived the tensioner I got for $28 shipped.

I already annealed the copper washer. I'll re use the casted housing from my bike and the acorn nut cause this one is painted black.

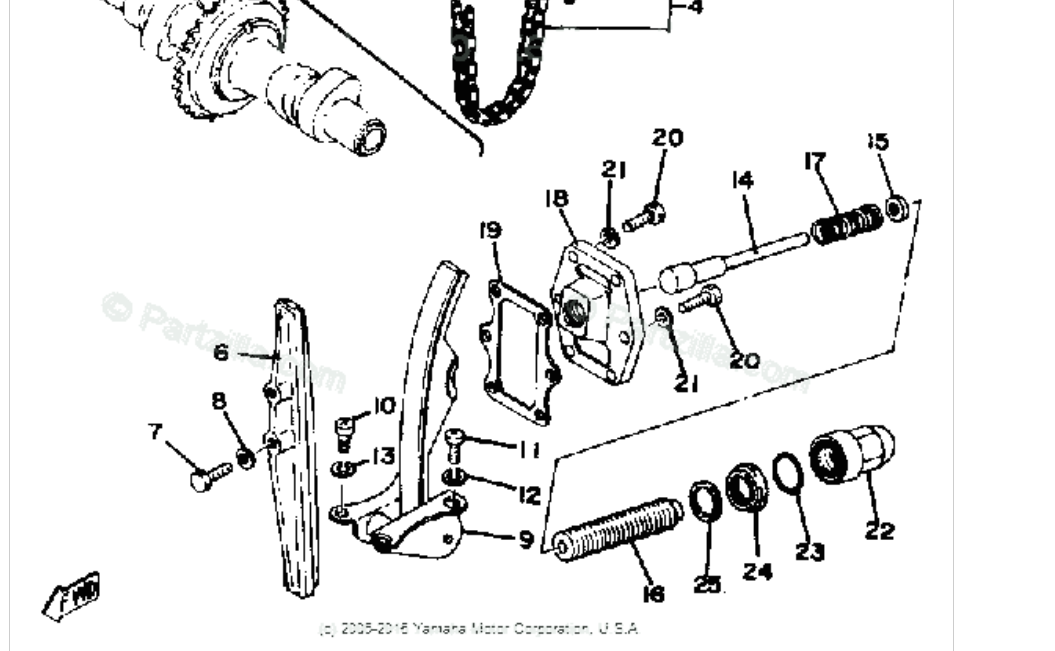

I am to set tension w/ plugs out, run starter and look for it to not go past the end but bounce about a mm inward?

EDIT: this package I got on ebay also had the timing chain off the bike. Timing chain was stretched about 1/8" from the new one I got recently and the one I took off my bike was 1/4" stretched from the new one, so the one that cam with this package stretched half as much as the one I pulled off my '78 bike. No clue how many miles it had.

Am I just setting torque wrench and then following the pattern and tightening or am I to back off some on all of them then tighten following pattern?

Also, I was following service manual I had that came with bike and it shows 25ft-lbs but found posts recently where you mention set to 30-35. I did not apply any anti seize to the threads. I just brushed them clean before putting back together. Please advise. thx

Today, arrived the tensioner I got for $28 shipped.

I already annealed the copper washer. I'll re use the casted housing from my bike and the acorn nut cause this one is painted black.

I am to set tension w/ plugs out, run starter and look for it to not go past the end but bounce about a mm inward?

EDIT: this package I got on ebay also had the timing chain off the bike. Timing chain was stretched about 1/8" from the new one I got recently and the one I took off my bike was 1/4" stretched from the new one, so the one that cam with this package stretched half as much as the one I pulled off my '78 bike. No clue how many miles it had.

Last edited:

You can do it that way. I think that's the way gggGary likes to do it. I like to check/adjust it as the engine sits there idling. I also like to do it on a warmed up motor. If you set it on a cold motor, it may end up too tight once hot and with the parts all expanded due to the heat. Most of the tensioner parts are the same on the type D and type E assemblies. The exception is the longer type E plunger of course, but the adjuster screw may differ in length as well. This was due to the 1mm thicker rubber/metal damper washer used on the latter type E assemblies. So, measure the length of your adjuster screws and whichever one you use, pair it with the correct damper washer (60mm long screw + 2mm thick copper damper washer or 59mm long screw with the 3mm thick rubber/metal damper washer). If you mismatch the parts, you'll get one of these scenarios and adjustment will be more difficult and confusing .....

One of these is what you want ......

I've revised my thinking on the head nut torque values, keeping them in the 28-30 lb. range now. I have tried up to 35 lbs in the past but I could feel it was really putting a strain on the studs. I do feel 25 lbs isn't enough. Also, this is on lubed fasteners, so you're actually applying more torque than on a dry fastener. So, for yours, I would remove the fasteners one at a time, lube them (I use anti-seize), then reinstall and bring up to around 25 lb. Once they're all done, go back and bring them up to 28 lbs. There's also the two bolts under the spark plugs. These are part of the head bolt fastening pattern so need to be checked when torquing the head. They are smaller so the torque spec for them is less (14 to 16 lbs I think). Again, if you installed them dry, remove them, lube them, then reinstall and torque. And lastly, there's the small M6 bolt at the rear between the carbs. Once the engine is installed, it's difficult to get a torque wrench on that one so you may just need to check and tighten it (if need be) by "feel" with a wrench. Just make it the normal tightness you would use for any other M6 bolt on the bike.

One of these is what you want ......

I've revised my thinking on the head nut torque values, keeping them in the 28-30 lb. range now. I have tried up to 35 lbs in the past but I could feel it was really putting a strain on the studs. I do feel 25 lbs isn't enough. Also, this is on lubed fasteners, so you're actually applying more torque than on a dry fastener. So, for yours, I would remove the fasteners one at a time, lube them (I use anti-seize), then reinstall and bring up to around 25 lb. Once they're all done, go back and bring them up to 28 lbs. There's also the two bolts under the spark plugs. These are part of the head bolt fastening pattern so need to be checked when torquing the head. They are smaller so the torque spec for them is less (14 to 16 lbs I think). Again, if you installed them dry, remove them, lube them, then reinstall and torque. And lastly, there's the small M6 bolt at the rear between the carbs. Once the engine is installed, it's difficult to get a torque wrench on that one so you may just need to check and tighten it (if need be) by "feel" with a wrench. Just make it the normal tightness you would use for any other M6 bolt on the bike.

ok, so thanks for that pic cause I did not realize/show the metal washer that came with it. w/o you posting that I would have put it together w/o it.

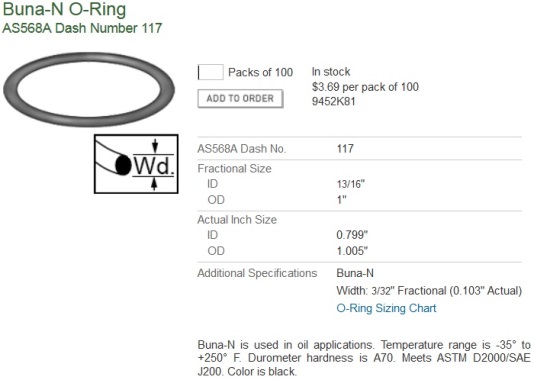

IT did not have the O ring with it, so I'll have to size an O ring from my O ring kits?

I also did not realize I needed to put it in.

Here are pics of the metal washer (w/o O ring) and a pic at the end of it showing the rod fully inserted.

IT did not have the O ring with it, so I'll have to size an O ring from my O ring kits?

I also did not realize I needed to put it in.

Here are pics of the metal washer (w/o O ring) and a pic at the end of it showing the rod fully inserted.

You'll want to flip the metal/rubber washer over so the slightly thicker and wider metal side faces the spring. The only o-ring in the assembly is the one in the acorn cover nut. There happens to be an American size that fits perfectly .....

You can just unscrew the old and in with the new. Only moving part inside is the shoe, and it's riveted to a pivot.

Thx Jim, was worried #14, #17 & #15 would fall in when removing it.

I finally had some time this evening, pulled the tank and top engine mount off to re torque the head bolts.

You all would not be surprised that the big nuts only took 20lbs to remove.

I finally had some time this evening, pulled the tank and top engine mount off to re torque the head bolts.

You all would not be surprised that the big nuts only took 20lbs to remove.

Not sure if it's possible for 'em to fall in or not. I don't think they can, but I'd be mindful of it.

The shaft on 14 already sticks out past the housing... #18, so it shouldn't really be possible for it to fall down inside.

The shaft on 14 already sticks out past the housing... #18, so it shouldn't really be possible for it to fall down inside.

ok that makes sense.Not sure if it's possible for 'em to fall in or not. I don't think they can, but I'd be mindful of it.

The shaft on 14 already sticks out past the housing... #18, so it shouldn't really be possible for it to fall down inside.

Shouldn't fall down inside because the chain is there. Even with the tensioner out, the chain won't be all that loose.

FINALLY have the valves set and started it up last night. Sounded good but I just idled for about half a minute.

Will swap the tensioner parts this weekend (monday off!)

Hope to get a test ride in now that rear tire is also new.

also plan to vinyl wrap the tank just to see how it will look when painted.

Busy weekend cause I just picked up another project bike. 82 XJ650. I already have an 83 XJ650 ( you can see the red one in the background of the pic)

I reworked the 83 last year so this will be familiar. I got it so cheap and with spare carbs, original seat, original fender, riding gear, 2 helmets I could not say no. Bike is hacked up some with different seat, turn signals, tail light and bars (cables are a bit of a mess) Besides his wife was about to give birth and wanted it out of the garage

Will swap the tensioner parts this weekend (monday off!)

Hope to get a test ride in now that rear tire is also new.

also plan to vinyl wrap the tank just to see how it will look when painted.

Busy weekend cause I just picked up another project bike. 82 XJ650. I already have an 83 XJ650 ( you can see the red one in the background of the pic)

I reworked the 83 last year so this will be familiar. I got it so cheap and with spare carbs, original seat, original fender, riding gear, 2 helmets I could not say no. Bike is hacked up some with different seat, turn signals, tail light and bars (cables are a bit of a mess) Besides his wife was about to give birth and wanted it out of the garage