Your picture doesn't make sense, you measured wrong, or something else.

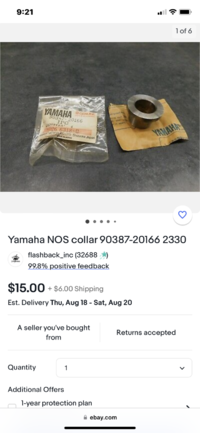

View attachment 221874

Directly below the long bearing spacer you show the left-side axle spacer with the pressed on dust cover, which looks silvery in your pic. That spacer and cover is the same for all years, and the outside diameter of the dust cover is 60mm. There is no way in the world that the long bearing spacer is 58 mm long, which would make it shorter than the spacer and dust cover below it in your pic.

The disc wheel inside bearing spacer is 98mm long, not 100mm. Re-measure yours. Post a pic with it alongside a metric ruler.