-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

rubber-tipped BS38 float needle answer

- Thread starter DogBunny

- Start date

I had a long phone conversation with TwoManyXS1Bs a couple days ago regarding using the Honda needles, modifying the seats, etc. 2M tends to be a lot smarter than me. We had a spirited debate on several points, and I didn't agree with all of his thoughts, but suffice it to say that I no longer like the idea of drilling the seat to allow the Honda needle to sit lower with a greater contact area. Again, it would just take too long to go into all of the details, but I think this is not the way.

This is 2M's pic from the second link in post #2 of this thread. It shows how to modify the float tang to accommodate the longer Honda needle. You don't want to just pry the tang up. The tang needs to be kept parallel to the rest of the float, and this requires two bends. This would be very fumbly, or even impossible to do with two sets of needle-nose pliers. But, it would be fairly easy to do by making a couple of little forms and and pressing the tang in a vice. This, I believe, is the way.

The angle of the Honda needle's Viton tip is 70°, and the angle of the stock BS38 needle is 60°. Presumably, that little bevel in the stock seat is also 60°. 2M regards the angle difference as a non-issue. In fact, he thinks it might actually aid in sealing and allow the Viton to seat-in better over time. 2M does recommend dressing that bevel. gggGary once described cleaning float valve seats by chucking up a Q-tip that has a bit of metal polish on it in a drill motor. This would be sufficient.

This is what I will try. I can no longer wait for the Chinese Honda needles that I bought and linked to in post #5 of this thread to arrive. So, I have bought more Honda needles from a U.S. seller.

https://www.ebay.com/itm/192195452506

These are the cheapest ones on eBay in case anyone else wants to try this experiment.

This is 2M's pic from the second link in post #2 of this thread. It shows how to modify the float tang to accommodate the longer Honda needle. You don't want to just pry the tang up. The tang needs to be kept parallel to the rest of the float, and this requires two bends. This would be very fumbly, or even impossible to do with two sets of needle-nose pliers. But, it would be fairly easy to do by making a couple of little forms and and pressing the tang in a vice. This, I believe, is the way.

The angle of the Honda needle's Viton tip is 70°, and the angle of the stock BS38 needle is 60°. Presumably, that little bevel in the stock seat is also 60°. 2M regards the angle difference as a non-issue. In fact, he thinks it might actually aid in sealing and allow the Viton to seat-in better over time. 2M does recommend dressing that bevel. gggGary once described cleaning float valve seats by chucking up a Q-tip that has a bit of metal polish on it in a drill motor. This would be sufficient.

This is what I will try. I can no longer wait for the Chinese Honda needles that I bought and linked to in post #5 of this thread to arrive. So, I have bought more Honda needles from a U.S. seller.

https://www.ebay.com/itm/192195452506

These are the cheapest ones on eBay in case anyone else wants to try this experiment.

"Polishing" the BS38 seats with Q-tips is all I've ever done. The Q-tip is a perfect fit after hand spinning in there with a polishing compound. A guy must be careful to not ruin the roundness of the brass seat using any thing hard.

The needles on the other hand. That wear ring can likely be the whole sealing problem? I can see debris or even just contamination film disrupting that seal. Again I just lightly polish needles and discard the ones that don't pass inspection lol

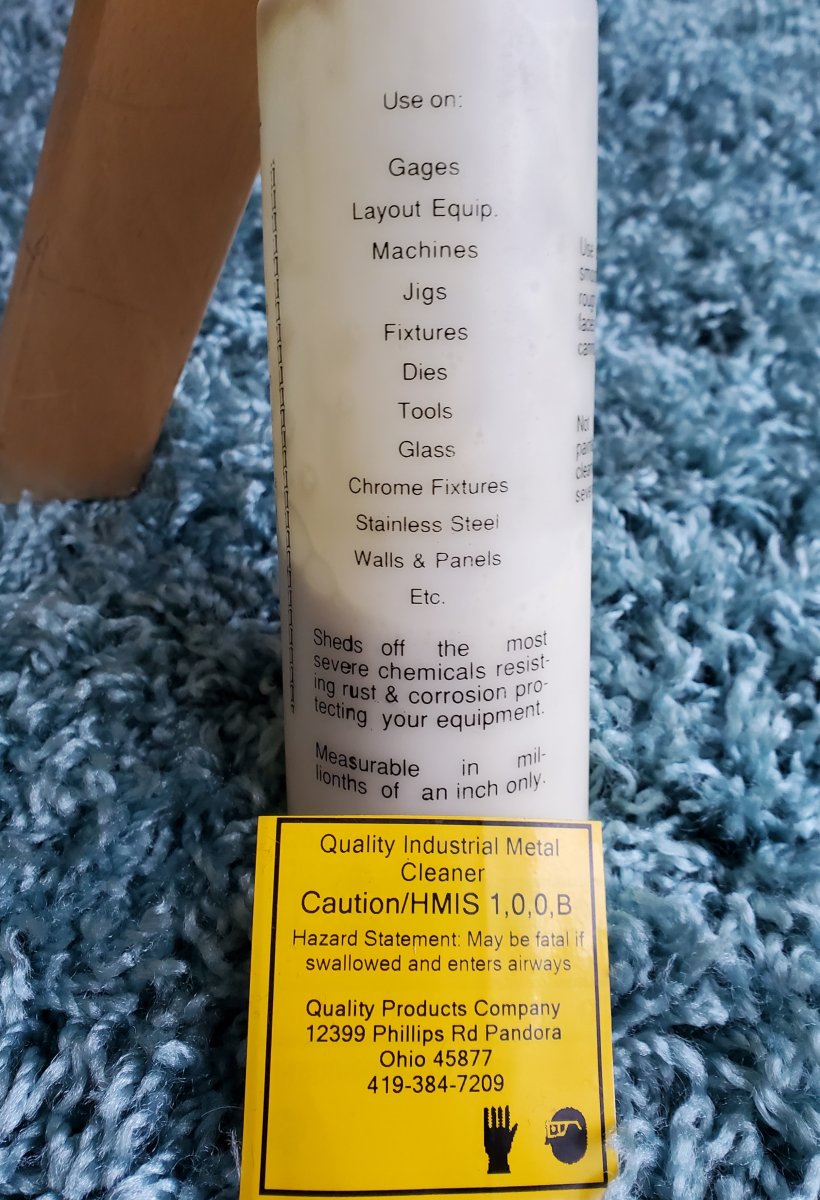

(fyi this is the best metal cleaner known to mankind)

The needles on the other hand. That wear ring can likely be the whole sealing problem? I can see debris or even just contamination film disrupting that seal. Again I just lightly polish needles and discard the ones that don't pass inspection lol

(fyi this is the best metal cleaner known to mankind)

Address is there on the bottle. Its "industrial" and doesn't even have a name. I've worked in many machine shops now, I can't even remember which cabinet shelf I found it on? (or can't say)

Still have 1/3rd of a bottle so lol. Its a very good chrome polish as well.

Still have 1/3rd of a bottle so lol. Its a very good chrome polish as well.

My U.S. seller Honda needles arrived. I have installed them, and they work great. I solved the needle height problem. The solution is incredibly simple.

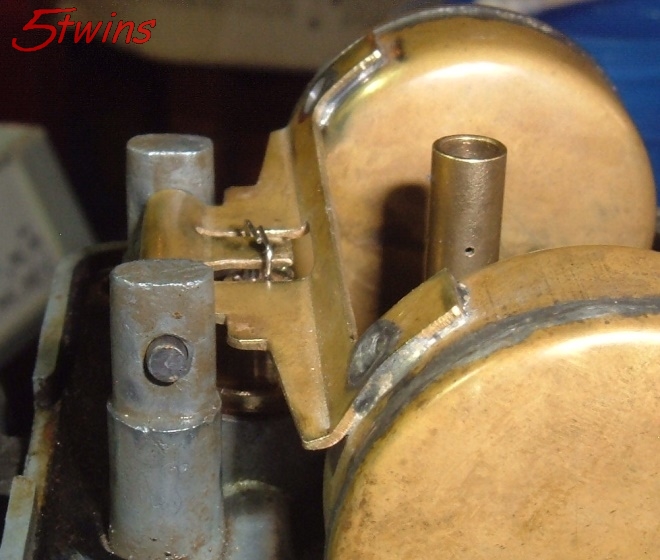

This is gggGary's pic from the other thread. A little hard to see, but it shows the steep tang angle that the longer Honda needle requires.

I initially got a similar result. I am using the same Honda needle, purchased from the same eBay seller. The truth is, after bouncing the tang up and down on the needle a few times, I think that this is probably perfectly adequate. But, we can do a lot better than this with a very simple change.

My tang after the change. Much improved. The other float looked even better -- the tang was pretty much perfectly parallel to the float yoke.

There is a washer that sits under the valve seat, Yamaha part # 214-14195-00-00. Actually, my pic shows the MikesXS replacement washer, which is aluminum. The stock washer is red and I think is fiber.

Anyways, all you have to do is eliminate this washer, and now the height of the Honda needle will be correct.

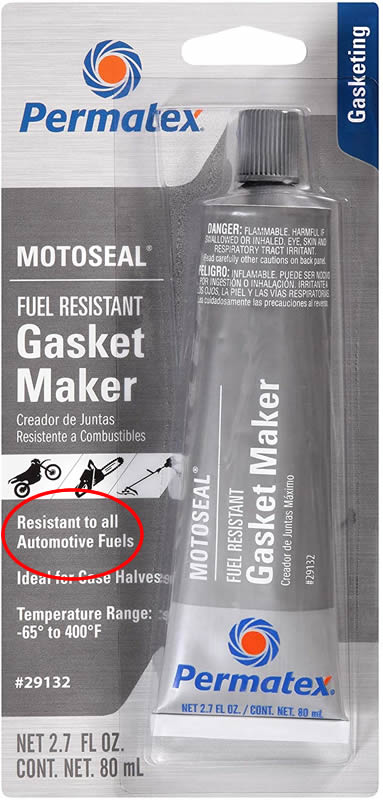

In place of the washer, I used this. ThreeBond, Yamabond, Hondabond, Motoseal -- I believe that all of these grey, non-hardening gasket makers are the same, and whichever you have on hand will work. I know that Motoseal is intended for surfaces that press together, not for surfaces that rotate together, but nonetheless, for this application it is working.

If you want to get really compulsive, you can use Permatex PermaShield Fuel Resistant Gasket Dressing & Flange Sealant, part # 85420. It specifically mentions ethanol resistance.

I applied the Motoseal to the mating surface. You could also try thread sealant applied to the threads. Even LocTite might work. Or Yellow Teflon tape.

I don't have long-term results yet, but I think this is a winner. I will probably never buy a stock Mikuni BS38 float valve again. Partzilla currently sells ONE float valve for $16.31, and that's before shipping.

https://www.ebay.com/itm/192195452506

I used the above listing, and bought FOUR Honda needles for $12.95 plus tax, delivered. Needles from Asian sellers are even less.

Obviously, you have to re-use your old seat. Polish the seat's orifice bevel by chucking up a Q-tip that has a bit of metal polish on it in a drill motor. Also polish the wall of the bore.

This is gggGary's pic from the other thread. A little hard to see, but it shows the steep tang angle that the longer Honda needle requires.

I initially got a similar result. I am using the same Honda needle, purchased from the same eBay seller. The truth is, after bouncing the tang up and down on the needle a few times, I think that this is probably perfectly adequate. But, we can do a lot better than this with a very simple change.

My tang after the change. Much improved. The other float looked even better -- the tang was pretty much perfectly parallel to the float yoke.

There is a washer that sits under the valve seat, Yamaha part # 214-14195-00-00. Actually, my pic shows the MikesXS replacement washer, which is aluminum. The stock washer is red and I think is fiber.

Anyways, all you have to do is eliminate this washer, and now the height of the Honda needle will be correct.

In place of the washer, I used this. ThreeBond, Yamabond, Hondabond, Motoseal -- I believe that all of these grey, non-hardening gasket makers are the same, and whichever you have on hand will work. I know that Motoseal is intended for surfaces that press together, not for surfaces that rotate together, but nonetheless, for this application it is working.

If you want to get really compulsive, you can use Permatex PermaShield Fuel Resistant Gasket Dressing & Flange Sealant, part # 85420. It specifically mentions ethanol resistance.

I applied the Motoseal to the mating surface. You could also try thread sealant applied to the threads. Even LocTite might work. Or Yellow Teflon tape.

I don't have long-term results yet, but I think this is a winner. I will probably never buy a stock Mikuni BS38 float valve again. Partzilla currently sells ONE float valve for $16.31, and that's before shipping.

https://www.ebay.com/itm/192195452506

I used the above listing, and bought FOUR Honda needles for $12.95 plus tax, delivered. Needles from Asian sellers are even less.

Obviously, you have to re-use your old seat. Polish the seat's orifice bevel by chucking up a Q-tip that has a bit of metal polish on it in a drill motor. Also polish the wall of the bore.

XSJohn reccomended cleaning the seats by stripping the cotton off a Q-tip and replacing it with 40 steel wool. Some spray carb cleaner and spinning this steel Q-tip with just you fingers. This cleans off the crud very well.

My float valves seal well.

No chuck it up, no need for power here. To easy to over do it and change the seats.

Leo

My float valves seal well.

No chuck it up, no need for power here. To easy to over do it and change the seats.

Leo

I took a look at some old BS34 viton needle seats and it seems they have very little, if any, bevel on their holes where the needle seats. So, I guess the lack of much bevel on the BS38 seats is a non-issue.

I will have to try this on the next bike.

Okay , now where did I leave that BS ....

"

Worn needle valve . Seems obvious , replace .

The damage from constant contact with a needle seat will show as a definite ring around the Nitrile rubber tip . This just won't work . However in most cases the best cleaning agent for even the most green and ugly needle valve is simply your fingers and a bit of mineral spirits . The problem with this repair is its only half of the sealing element .

Dirty , worn or damaged needle valve seat . Simple enough ,replace .

Simple yes but not always the cause . A needle valve seat can be brought back to life with a little ingenuity . Remove the needle valve and leave the seat in the carb body for now . Find a drill bit whose shank , not drill , just fits in the seat . Cut the shank off the drill and chuck it up in a drill motor . Go over to a grinding wheel and attempt to reproduce the angle of the needle valve Viton/Nitrile tip on the exposed end . Finish this pointed down onto the side of the wheel . The reason for this is we are building a make shift valve seat cutter and using the grind marks as cutting teeth . Turn the shank around and do the same to the other end only this time the angle should be around 15 to 20 degrees . Those of you that have ground valve seats get busy as I explain the rest . Take a q-Tip and a bit of scotchbrite and either by hand or in a well controlled cordless drill and clean the valve seat . By hand take a few turns with the 15 degree end of the shank in the seat and observe the results . If you can see a definite bright ring all the way around the seat you're done . If more work is needed it may help to stick a bit of fuel line over the shank and use that to turn the shank . If that doesn't work by all means get out the fine valve grinding compound and use the drill motor . The seat was wasted anyway all you can do now is waste time . Do the same with the other end of the shank and attempt to establish the seat . This takes very little pressure and happens usually very quickly . Problem is after all this you may still have the problem and the needle and seat despite initial observations were not the cause ."

from https://www.xs650.com/threads/carburettors-from-the-grave.34737/

"

Worn needle valve . Seems obvious , replace .

The damage from constant contact with a needle seat will show as a definite ring around the Nitrile rubber tip . This just won't work . However in most cases the best cleaning agent for even the most green and ugly needle valve is simply your fingers and a bit of mineral spirits . The problem with this repair is its only half of the sealing element .

Dirty , worn or damaged needle valve seat . Simple enough ,replace .

Simple yes but not always the cause . A needle valve seat can be brought back to life with a little ingenuity . Remove the needle valve and leave the seat in the carb body for now . Find a drill bit whose shank , not drill , just fits in the seat . Cut the shank off the drill and chuck it up in a drill motor . Go over to a grinding wheel and attempt to reproduce the angle of the needle valve Viton/Nitrile tip on the exposed end . Finish this pointed down onto the side of the wheel . The reason for this is we are building a make shift valve seat cutter and using the grind marks as cutting teeth . Turn the shank around and do the same to the other end only this time the angle should be around 15 to 20 degrees . Those of you that have ground valve seats get busy as I explain the rest . Take a q-Tip and a bit of scotchbrite and either by hand or in a well controlled cordless drill and clean the valve seat . By hand take a few turns with the 15 degree end of the shank in the seat and observe the results . If you can see a definite bright ring all the way around the seat you're done . If more work is needed it may help to stick a bit of fuel line over the shank and use that to turn the shank . If that doesn't work by all means get out the fine valve grinding compound and use the drill motor . The seat was wasted anyway all you can do now is waste time . Do the same with the other end of the shank and attempt to establish the seat . This takes very little pressure and happens usually very quickly . Problem is after all this you may still have the problem and the needle and seat despite initial observations were not the cause ."

from https://www.xs650.com/threads/carburettors-from-the-grave.34737/

One time I noticed a needle on a BS34 could or was getting cocked sideways in a seat, hanging on the edge, and wouldn't go down. I made a small bevel around the opening with the tip of a pocket knife and it wouldn't hang after that. Non-Mikuni replacements if I remember right, not recommended parts.

Last edited:

Can a compressible O-ring be used, or maybe a thinner copper washer? (Thanks).In place of the washer,

'TT'

If the mating surfaces look good, a paper-thin copper washer might be a good idea. But, now you're spending more money. Would be interesting to see if they make any in a size that would work, and for how much.Can a compressible O-ring be used, or maybe a thinner copper washer? (Thanks).

'TT'

There is always a grinder and a dremel. But would the crush conform without obstruction.If the mating surfaces look good, a paper-thin copper washer might be a good idea. But, now you're spending more money. Would be interesting to see if they make any in a size that would work, and for how much.

'TT'

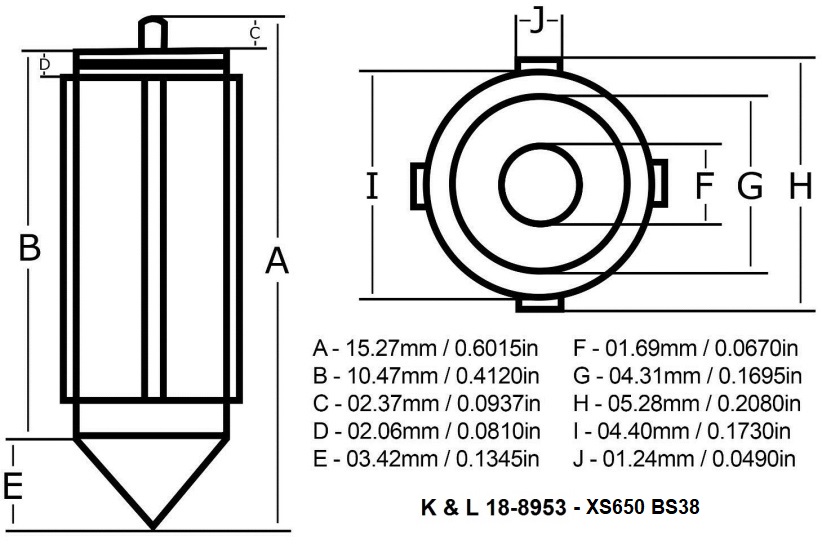

I'm trying out a couple of these viton needles (K&L 18-8953) right now. I pulled them from some Honda VT600C rebuild kits I got off Craigslist for a song. I bought them just to get the needles. I looked up this bike in the K&L catalog and verified it took the 18-8953 needles .....

Yes, they are a bit longer than the originals .....

..... but I didn't encounter the sharp tang angle issue like DB did. They installed quite nicely .....

I think there's several reasons for this. First, these went in some carbs being set to '76-'77 specs and they call for a float level of 25mm. Most other years use 24mm and that would give a sharper tang angle. Next, I'm using the original red fiber washers on the seats. I think they're probably thinner than the aluminum ones. And the last thing - even though these kit needles should be the 18-8953 ones, they are a little shorter than the ones in an 18-8953 package I ordered.

Anyway, so far they seem to be working well. That's why I ordered more. If they hold up well, I'll be using them in more BS38s.

Yes, they are a bit longer than the originals .....

..... but I didn't encounter the sharp tang angle issue like DB did. They installed quite nicely .....

I think there's several reasons for this. First, these went in some carbs being set to '76-'77 specs and they call for a float level of 25mm. Most other years use 24mm and that would give a sharper tang angle. Next, I'm using the original red fiber washers on the seats. I think they're probably thinner than the aluminum ones. And the last thing - even though these kit needles should be the 18-8953 ones, they are a little shorter than the ones in an 18-8953 package I ordered.

Anyway, so far they seem to be working well. That's why I ordered more. If they hold up well, I'll be using them in more BS38s.

Wouldn't it work just like the stock washer? Assuming good mating surfaces.

Interesting observation. Strange that the same part number from the same supplier yields two different lengths. The shorter ones you got look prefect. But the longer ones can be made to work too.even though these kit needles should be the 18-8953 ones, they are a little shorter than the ones in an 18-8953 package I ordered.

The shorter kit needles are several years old so probably from a different production run. The length difference was in how much pin was sticking out, the bodies appeared the same. I've found some dimensioned drawings of the needles and while I haven't actually measured one for comparison, I probably should. I should probably measure some original all steel ones as well. Here's the 8953 .....

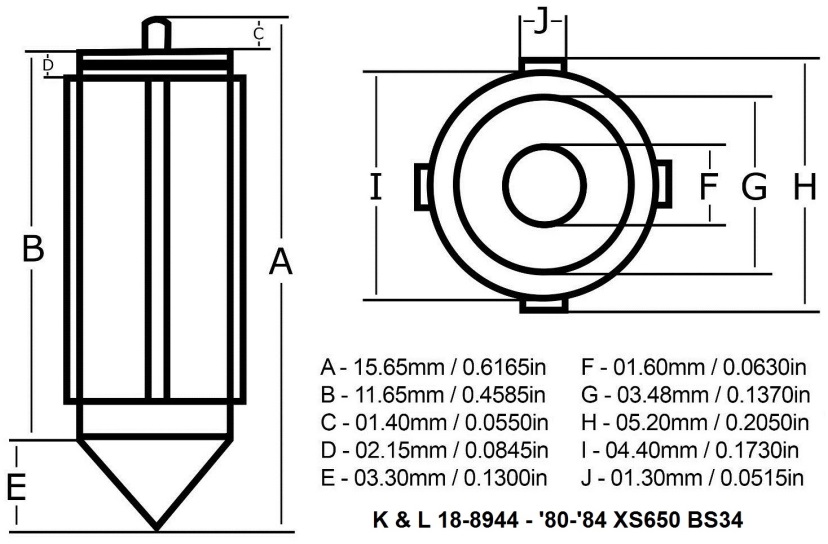

..... and here's the 8944, their BS34 replacement. It's even longer than the 8953 so we wouldn't want that .....

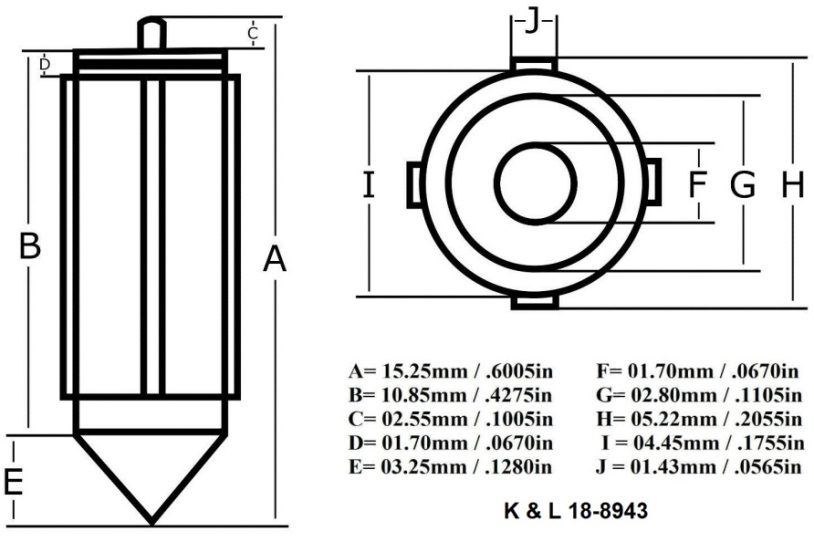

The only other viable alternative I ran across was the 18-8943. This one is a hair shorter than the 8953 but it's diameter is also smaller, so I'm not sure that would work. That's why I should check some originals .....

..... and here's the 8944, their BS34 replacement. It's even longer than the 8953 so we wouldn't want that .....

The only other viable alternative I ran across was the 18-8943. This one is a hair shorter than the 8953 but it's diameter is also smaller, so I'm not sure that would work. That's why I should check some originals .....

Just a heads up @JRP1 tried viton tipped needles in his TX-A and ended up removing them after much frustration with intermittant flooding. Replaced with Mikuni needles and seats all good. Not sure of the brand YRMV etc. Really hope 5twins experiment goes well long term.

Similar threads

- Replies

- 100

- Views

- 15K

- Replies

- 69

- Views

- 17K