Hi,

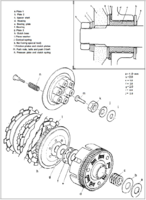

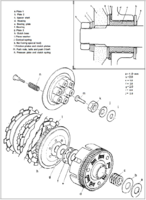

Couple years ago, i noticed my xs650 clutch worm gear has no ball in it so i bought one, but it never fitted there. Ball was right size but there was no slack at all with it. Clutch worked quite well so i drove that summer with smaller worm ball. Now clutch has started slipping and i decided to make some fix. I orderer clutch repair kit, needle bearing, 6 socket spring screws and sleeves. Also cushion springs behind the basket were broken so i bought repair kit and long type pushrod. When i swapped those short and long pushrod, i noticed there was all three bearing ball inside the engine. One was behind push crown rod and two was between the short rods. Also needle bearing was not between the washers. There was bearing against basket, thin and thick washer on it. I installed everything according this:

I adjusted clutch cable and worm and smoothly tested it without motor oil (friction plates were in bath) but it does not disengage. The clutch boss is moving when pulling lever. I guess i should not do that without oil..am i right? Anyway im wondering now did i do everything correctly..

Couple years ago, i noticed my xs650 clutch worm gear has no ball in it so i bought one, but it never fitted there. Ball was right size but there was no slack at all with it. Clutch worked quite well so i drove that summer with smaller worm ball. Now clutch has started slipping and i decided to make some fix. I orderer clutch repair kit, needle bearing, 6 socket spring screws and sleeves. Also cushion springs behind the basket were broken so i bought repair kit and long type pushrod. When i swapped those short and long pushrod, i noticed there was all three bearing ball inside the engine. One was behind push crown rod and two was between the short rods. Also needle bearing was not between the washers. There was bearing against basket, thin and thick washer on it. I installed everything according this:

I adjusted clutch cable and worm and smoothly tested it without motor oil (friction plates were in bath) but it does not disengage. The clutch boss is moving when pulling lever. I guess i should not do that without oil..am i right? Anyway im wondering now did i do everything correctly..

Last edited: