BigBoreSwede

XS650 Addict

Hello.

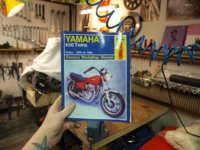

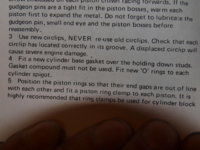

According to the "Holy Bible" there should be O-rings on the cylinder spigots. This makes me go

since I simply don´t know where to put these O-rings.

since I simply don´t know where to put these O-rings.

It was not any O-rings when I lifted the cylinder from the bottom.

Hmmm.......

/BigBoreSwede

According to the "Holy Bible" there should be O-rings on the cylinder spigots. This makes me go

It was not any O-rings when I lifted the cylinder from the bottom.

Hmmm.......

/BigBoreSwede