-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

fresh rebuild, first start, advance mech destroyed?

I found the pin and now it seems like the cam has moved in. When i put the pin in, it is hitting the inside of the bearing cover and it wasn't like that before i started it. What would cause the cam to move towards the ignition side? Now there is some chipping around the hole where the pin goes that was caused by this accident.

the bearings were seated all the way on to the cam. I think the pin hitting the back side of that advance unit forced the cam in a little. I just tapped it with a hammer from the ignition side and it now sits correct. I probably have to re-seat those bearings on the ignition side. Is there a way to do it without removing the head cover? big socket maybe?

do any other bikes share the same unit? If im going to spend 70 on a new unit I might as well by the e-advancer that pamco sells.

Look at it this way....................this is actually a lucky day for you. The mechanical advance, while they worked quite well for the first 20 or 30 years, have now lost their precision and best to retire them to a museum. The pamco E-advance works extremely well and will be reliable....................a great addition to your bike.

You could try loosening the head nuts on the points side and driving the bearings in with a socket. Be aware that this is a very precise setting. You want the cam perfectly centered in the head so its sprocket aligns with the one on the crank below it. The bearings will be inset on both sides. Measure that inset and make sure its equal.

pamcopete

Ride.Enjoy.Life is Simple

You could try loosening the head nuts on the points side and driving the bearings in with a socket. Be aware that this is a very precise setting. You want the cam perfectly centered in the head so its sprocket aligns with the one on the crank below it. The bearings will be inset on both sides. Measure that inset and make sure its equal.

5twins,

So, there is nothing that holds the cam and bearings laterally?

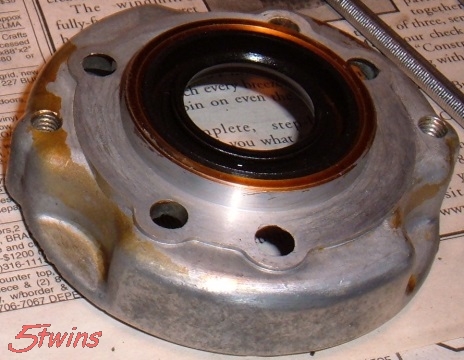

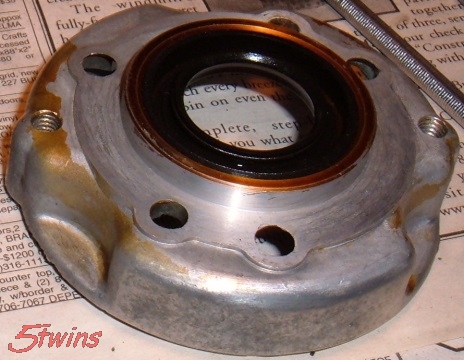

The top cover clamps down on the bearings and holds them (and the cam). At first glance, this looks wrong because the inner bearing hangs off the casting a little, but its the way it has to be. The bearings need to pushed in as far as they'll go on the cam so it can't "float" left and right while spinning, throwing the sprocket alignment off. The bearings must be inset into the head to allow the points and advance housings to seat fully and seal. The housings have a step on the back that sits into the bearing inset .....

tonyc

XS650 Guru

Brew he stated That the bearings need to be pushed far as they can go on the cam. Then the cam is centered on the head. Good luck Tony C

Last edited:

With the head cover on and bearings seated all the way to the stops on the camshaft, the outer bearing races should be inset an equal distance on their journals. You can measure this with the depth gauge of a caliper.

pamcopete

Ride.Enjoy.Life is Simple

The top cover clamps down on the bearings and holds them (and the cam). At first glance, this looks wrong because the inner bearing hangs off the casting a little, but its the way it has to be. The bearings need to pushed in as far as they'll go on the cam so it can't "float" left and right while spinning, throwing the sprocket alignment off. The bearings must be inset into the head to allow the points and advance housings to seat fully and seal. The housings have a step on the back that sits into the bearing inset .....

I have had reports of the PAMCO plate protruding to the extent that the components make contact with the magnetic rotor. This is caused by a too thick gasket for the points and advancer housings which would then leave the cam and bearings with no actual limit to their lateral movement and be dependant entirely on the proper placement of the cam and bearings upon installation. So, if the gaskets are too thick, can the cam and bearings move laterally? Or are the housings supposed to contact the cam bearings?

Once the top cover is installed and tightened down, the cam and bearings shouldn't move side to side, even if there is a little space between the housings and the bearings. I've never checked whether the housings actually touch the bearings, but I'm going to. I want to find out if I can drive the housing seals in a bit further, so they protrude out the back of the housing slightly and don't hit the bearings. The ends of the cam don't stick out through the seals very much at all so setting them in further may help them seal better. In particular, this can be a problem with the MikesXS "improved" triple lip seals. The added lips are on top, towards the outer side of the seal, and sometimes don't even get bearing on the cam. That makes these replacements more prone to leaking than originals.

Similar threads

- Replies

- 42

- Views

- 966

- Replies

- 8

- Views

- 801