There's a guy up in Michigan using Nascar used titanium 7 or 6mm stem valves for his super exotic XS 900 that pumps out over 100HP,so any time you can reduce resistance as the air encounters a turn,you'll most like see an increase in flow,what you want to stay away from is cut down valve stems. Those liners can be just as costly as new guides but what would a custom set guides cost for 7mm valves?

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

MikesXS Stainless Valves - Anyone else having trouble with them?

- Thread starter Punkskalar

- Start date

-

- Tags

- engine

Punkskalar

Hugh's HandBuilt

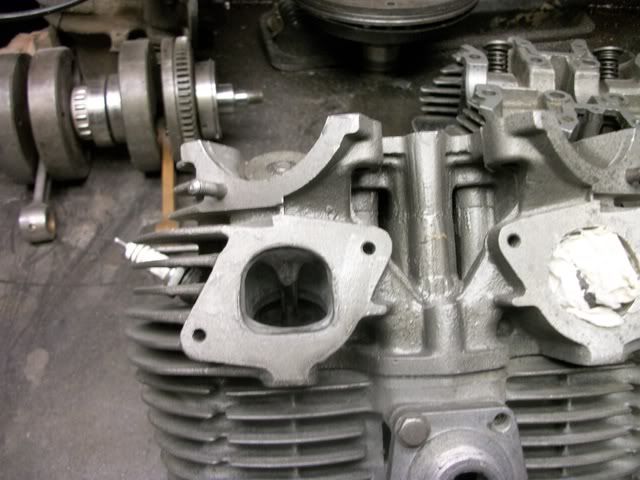

OK, tore into the engine again today. I measured all the stainless valves, the guides, etc... Brand New Viton Valve Seals looked fine with no damage or tears.

Found a set of 35 Year Old XS650 Valves on my shelf, and measured the valve stem in 3 locations on them.

35 Year Old Stock XS650 Intake Valve Measurements

Bottom of valve stem - .3141"

Middle of valve stem - .3141"

Top of valve stem - .3141"

Pretty Consistent Measurements on that valve.

35 Year Old Stock XS650 Exhaust Valve Measurements

Bottom of valve stem - .3136"

Middle of valve stem - .3136"

Top of valve stem - .3136"

Consistent Measurements on that valve as well.

------------------------------------------------------------------------------------

MIKESXS Stainless Valves

Intake #1

Bottom - .3136"

Middle - .3135"

Top - .3134"

An Obvious Taper on the stem, and smaller than a 35 year old stock stem.

Intake #2

Bottom - .3139"

Middle - .3137"

Top - .3136"

Again, an Obvious Taper on the stem, and a smaller OD than a 35 year old stock valve.

Exhaust #1

Bottom - .3138"

Middle - .3138"

Top - .3138"

Consistent Stem Diameter, Larger than stock valve (not by much, probably dead on to what it needs to be)

Exhaust #2

Bottom - .3137"

Middle - .3139"

Top - .3140"

Another tapered stem, tapered in the opposite direction than the intakes though. Size is larger than stock 35 year old Exhaust Valve

I measured all my guides as well.

Intake #1 - .3154" ID

Intake #2 - .3153" ID

Exhaust#1 - .3155" ID

Exhaust#2 - .3152" ID

I am going to get the valves and measure the side to side play as suggested in the manual, but for now, all I can say is that the NEW Stainless Valves are not consistent in sizes, nor do have they straight stems. Exhaust Valves OD seem to be a proper measurement, but the Intake Valves are consistently smaller than 35 year old stock XS valves. Might be why I could see oil coming down the valve stems into the intake when I pulled my carbs off..

Im back down to the shop, just wanted to record these measurements and get an update on this thread for you guys. After I measure the side-side play in the valves/guides, I will get back as well. I'll measure the stock valves and the new MikesXS Stainless Valves.

Hugh

Valve End Play @ 10MM above the seat.

Intake #1

Stock Valve - .0030

MikesXS SS - .0075

Intake #2

Stock Valve - .0030

MikesXS SS- .0057

Exhaust #1

Stock Valve - .0031

MikesXS SS - .0042

Exhaust #2

Stock Valve - .0032

MikesXS SS - .0041

Conclusion! My valve guides are in fair shape, but matched with the MikesXS Stainless Steel Valves, there is way to much slop in the valves to guide clearance.. If I use stock 35 year old valves, it appears as though I will be well within stock specs. It is a shame that these Stainless Valves are not useable, and I will be asking MikesXS for a refund or store credit. Im not holding my breath though. The intake valves appear to much worse, but there is a much more allowable tolerance in the Exhaust Valves, so that helps.

I will be installing new guides since I already have some here, and I will also be installing 35 year old stock valves. This should fix my oil in the intake problem. I guess I could reuse the stainless valves, but given the poor dimension consistency, I don't see the point in messing with it at this point...

A

Found a set of 35 Year Old XS650 Valves on my shelf, and measured the valve stem in 3 locations on them.

35 Year Old Stock XS650 Intake Valve Measurements

Bottom of valve stem - .3141"

Middle of valve stem - .3141"

Top of valve stem - .3141"

Pretty Consistent Measurements on that valve.

35 Year Old Stock XS650 Exhaust Valve Measurements

Bottom of valve stem - .3136"

Middle of valve stem - .3136"

Top of valve stem - .3136"

Consistent Measurements on that valve as well.

------------------------------------------------------------------------------------

MIKESXS Stainless Valves

Intake #1

Bottom - .3136"

Middle - .3135"

Top - .3134"

An Obvious Taper on the stem, and smaller than a 35 year old stock stem.

Intake #2

Bottom - .3139"

Middle - .3137"

Top - .3136"

Again, an Obvious Taper on the stem, and a smaller OD than a 35 year old stock valve.

Exhaust #1

Bottom - .3138"

Middle - .3138"

Top - .3138"

Consistent Stem Diameter, Larger than stock valve (not by much, probably dead on to what it needs to be)

Exhaust #2

Bottom - .3137"

Middle - .3139"

Top - .3140"

Another tapered stem, tapered in the opposite direction than the intakes though. Size is larger than stock 35 year old Exhaust Valve

I measured all my guides as well.

Intake #1 - .3154" ID

Intake #2 - .3153" ID

Exhaust#1 - .3155" ID

Exhaust#2 - .3152" ID

I am going to get the valves and measure the side to side play as suggested in the manual, but for now, all I can say is that the NEW Stainless Valves are not consistent in sizes, nor do have they straight stems. Exhaust Valves OD seem to be a proper measurement, but the Intake Valves are consistently smaller than 35 year old stock XS valves. Might be why I could see oil coming down the valve stems into the intake when I pulled my carbs off..

Im back down to the shop, just wanted to record these measurements and get an update on this thread for you guys. After I measure the side-side play in the valves/guides, I will get back as well. I'll measure the stock valves and the new MikesXS Stainless Valves.

Hugh

Valve End Play @ 10MM above the seat.

Intake #1

Stock Valve - .0030

MikesXS SS - .0075

Intake #2

Stock Valve - .0030

MikesXS SS- .0057

Exhaust #1

Stock Valve - .0031

MikesXS SS - .0042

Exhaust #2

Stock Valve - .0032

MikesXS SS - .0041

Conclusion! My valve guides are in fair shape, but matched with the MikesXS Stainless Steel Valves, there is way to much slop in the valves to guide clearance.. If I use stock 35 year old valves, it appears as though I will be well within stock specs. It is a shame that these Stainless Valves are not useable, and I will be asking MikesXS for a refund or store credit. Im not holding my breath though. The intake valves appear to much worse, but there is a much more allowable tolerance in the Exhaust Valves, so that helps.

I will be installing new guides since I already have some here, and I will also be installing 35 year old stock valves. This should fix my oil in the intake problem. I guess I could reuse the stainless valves, but given the poor dimension consistency, I don't see the point in messing with it at this point...

A

Last edited:

What's that old saying " you get what you pay for " you're not gonna get a quality product from Chinese labor camps

Punkskalar

Hugh's HandBuilt

What's that old saying " you get what you pay for " you're not gonna get a quality product from Chinese labor camps

If I paid Chinese Labor Camp prices, I'd be ok with it

But yeah, I feel like I have been the test bed for good and bad parts from Mikes...

But yeah, I feel like I have been the test bed for good and bad parts from Mikes...Instead of replacing valve guides, is knurling and resizing the guides a viable option.

When I was young knurling guides was often done. Some perfered it to replacement. Knurled guides had small indentations that held a small bit of oil in them. This helped maintain the oil film better than a smooth guide did. Like dimpling the piston skirts helped maintain the oil film and reduce skirt wear.

When I was young knurling guides was often done. Some perfered it to replacement. Knurled guides had small indentations that held a small bit of oil in them. This helped maintain the oil film better than a smooth guide did. Like dimpling the piston skirts helped maintain the oil film and reduce skirt wear.

Punkskalar

Hugh's HandBuilt

Instead of replacing valve guides, is knurling and resizing the guides a viable option.

When I was young knurling guides was often done. Some perfered it to replacement. Knurled guides had small indentations that held a small bit of oil in them. This helped maintain the oil film better than a smooth guide did. Like dimpling the piston skirts helped maintain the oil film and reduce skirt wear.

I have no idea how you would knurl the inside of the guides. Mine all measured to be in good spec. Got the engine reassembled last night and fired up with 35 year old valves. So far, no smoke

Wow I didn't know valves were so damn picky about tolerances! 3/10,000ths of an inch is tiny! You'd think the guides and seals wouldn't have a problem with that little of variance. Shit.. I've read about using 36mm forks seals on 35mm forks with no oil leak problems! That's 394/10,000ths of an inch difference!

Punkskalar

Hugh's HandBuilt

Yeah, some of them were almost a full .001" off though. If you ever get to do any machining like I do, you'll realize quick just how much material that is. I think it was the tapering of the stems and side-side play that allowed so much oil to make its way past the guides...

Talk to some oldtimers at a machine shop about knurling. As I remember the tool was expandable and you put it in and tightened the tool then turned it with a handle and as you turned the tool it knurled the guide and fed it self along the guide.

The knurling raised the metal inside the guide and makes the hole smaller diameter and then you reamed the guide back to the size you want.

This wouldn't help much on the tapered valve stems but you could make the hole in the guide match the straight stems.

In high school I went to a Vocational school for Agricultural Mechanics, working on farm eguipment. They had all the valve grinding eguipment including guide knurling and reaming tools. One kid brought in an old junk Chevy head and we used all thise tools on thatn head to learn how to do it.

I think if I have a head that needs guides I'll see about getting them knurled and reamed to spec.

The knurling raised the metal inside the guide and makes the hole smaller diameter and then you reamed the guide back to the size you want.

This wouldn't help much on the tapered valve stems but you could make the hole in the guide match the straight stems.

In high school I went to a Vocational school for Agricultural Mechanics, working on farm eguipment. They had all the valve grinding eguipment including guide knurling and reaming tools. One kid brought in an old junk Chevy head and we used all thise tools on thatn head to learn how to do it.

I think if I have a head that needs guides I'll see about getting them knurled and reamed to spec.

I remember knurled valve guides.

I'm glad for the info in this thread. I'm sure a lot here share my worst nightmare of a part that won't work after it's carefully installed and sealed up. Keep 'em coming.

I'm glad for the info in this thread. I'm sure a lot here share my worst nightmare of a part that won't work after it's carefully installed and sealed up. Keep 'em coming.

8mm Guide knurler here if interested:

http://cgi.ebay.com/ebaymotors/K-li...285QQptZLHQ5fDefaultDomainQ5f100#ht_500wt_956

Hope it helps.

Edit:

http://cgi.ebay.com/ebaymotors/K-li...285QQptZLHQ5fDefaultDomainQ5f100#ht_500wt_956

Hope it helps.

Edit:

Don't do it,leaves a path for oil to travel downwards into the ports.

Last edited:

Punkskalar

Hugh's HandBuilt

8mm Guide knurler here if interested:

http://cgi.ebay.com/ebaymotors/K-li...285QQptZLHQ5fDefaultDomainQ5f100#ht_500wt_956

Hope it helps.

Learning something new everyday... Mine were within spec, but I'll look into that next time...

Don't do it,leaves a path for oil to travel downwards into the ports.Learning something new everyday... Mine were within spec, but I'll look into that next time...

What jack said; Don’t do it- knurling that is. Jack will prolly have something to say about what Im gonna suggest; I built Triumph twins for most of my adult life, know all the go fast guys; we never ran anything but bronze valve guides. In turn I have never built a XS head with anything BUT BRONZE VALVE GUIDES and KIBBLEWHITE VALVES 1mm over on both the intake and exhaust. I live next door to Larry Morgan (pro stock Larry Morgan) I use his flow bench/tools to port my heads.(sold my superflow years ago) I’ll put my heads up agenst anyone’s on the street or track.; with that said, if your building a (proper XS motor) why use anything but bronze guides??? No, they don’t last as long , but they are sooo much better for your motor. and BUY GOOD VALVES. dont settel for he-said she-said BS

bikerjack

XS650 Enthusiast

This is good stuff to know about the valves. Just acquired a 77 XS650 that was sitting in the mud up past the bottom of the frame. After removing the left side cover, put the socket to it and got it to turn over. Looked in the exhaust ports and both valves move up and down, even though they are carboned beyond belief and dont seat all the way down.

BigJimmyW13

XS650 Guru

So your saying dont get the performance valves? I should just rework my current ones? Glad I hadn't ordered them yet...

Posted via Mobile

Posted via Mobile

What jack said; Don’t do it- knurling that is. Jack will prolly have something to say about what Im gonna suggest; I built Triumph twins for most of my adult life, know all the go fast guys; we never ran anything but bronze valve guides. In turn I have never built a XS head with anything BUT BRONZE VALVE GUIDES and KIBBLEWHITE VALVES 1mm over on both the intake and exhaust. I live next door to Larry Morgan (pro stock Larry Morgan) I use his flow bench/tools to port my heads.(sold my superflow years ago) I’ll put my heads up agenst anyone’s on the street or track.; with that said, if your building a (proper XS motor) why use anything but bronze guides??? No, they don’t last as long , but they are sooo much better for your motor. and BUY GOOD VALVES. dont settel for he-said she-said BS

: and so would I

: and so would IPunkskalar

Hugh's HandBuilt

: and so would I

You MIG welding up those chambers? What kinda filler you using? ER70 of some sort? No pop up pistons for those huh!

And I've been reading about Jack's Headwork long enough to know, that anyone wanting to compare their "Handywork" to Jack's is gonna have a tough fight ahead of them...

Similar threads

- Replies

- 32

- Views

- 1K